| Back to Back Issues Page | ||||||||||||

|

||||||||||||

|

PWL#122 - More on Duplex Stainless Steels, Aluminum Welding Safety Tips, Hydrogen control for filler October 01, 2013 |

||||||||||||

| We hope you will find this Letter interesting and useful. Let us know what you think of it.

PWL#122 More on Duplex Stainless Steels, Aluminum Welding Safety Tips, Care of Filler Metal for Hydrogen Control, Integrated Computational Materials Engineering (ICME), Welding Remote Control for Improved Safety, Friction Welding Processes (R), Friction Stir Welding Equipment (R) and much more...

October 2013 - Practical Welding Letter - Issue No.122

The Mid September 2013 Issue of Practical

Welding Letter, Bulletin 89, introducing Online Resources on Duplex Stainless Steels was distributed by e-mail.

DON'T USE REPLY to send your messages! Use the Contact Us form instead.

You are urged to pass-along this publication to your friends, if you like it, and if you think it may help them. If you received this from a friend and if you like what you read, please subscribe free of charge and you will also receive a bonus book on Practical HARDNESS TESTING Made Simple. The addresses reported hereafter were live and correct at the time of their publication. There is no guarantee that they will always be so, because they are administered by the sources themselves and are under their control. Note: References to articles or other documents are given here in If they are URL's (Uniform Resource Locator), which is the analogue of an address, they begin with "http://..." or "www.". These are not live and must be copied and pasted entirely into the browser (after having been selected with the mouse or otherwise). If they are long they may be displayed in two or more lines. In that case one has to care that the URL be copied completely in a single line without any space, and Enter. If the information is important to you as we hope, you may save the selected pages in a suitable folder on your Computer for easy reference. You are welcome to forward this page to those of your friends who may profit of this information.

1 - Introduction 2 - Article - More on Duplex Stainless Steels 3 - How to do it well: Aluminum Welding Safety Tips 4 - Filler Metal Care for Hydrogen Control 5 - Online Press: recent Welding related Articles 6 - Terms and Definitions Reminder 7 - Article: Integrated Computational Materials Engineering (ICME) 8 - Site Updating: Friction Welding Processes (R), 9 - Short Items 10 - Explorations: beyond the Welder 11 - Contributions: Welding Remote Control for Improved Safety 12 - Testimonials 13 - Correspondence: a few Comments 14 - Bulletin Board

2 - Article - More on Duplex Stainless Steels by Naddir M Patel

Note: Thank you for the very informative article on duplex stainless steels. [The article Duplex Stainless Steels - Best Practices for Selection and Welding was published (2) in Issue 121 of Practical Welding Letter for September 2003. Click on PWL#121 to see it. I have a suggestion regarding welding procedure qualification. In addition to Charpy specimens, I would also encourage having a set of micrograph samples made by a metallurgical lab to verify the austenite/ferrite balance in the weld metal

and HAZ has been achieved. The article Author, Mr. Naddir M Patel, kindly offered the following Comment: Thanks for the feedback. I had not suggested the requirement for microstructure analysis because that is standard procedures suggested in API technical report 938C. API TR 938-C As such, a reference to this API specification in the follow up note to the article would definitely give good information to a reader new to DSS. Additional Testing: The ferrite content of the weld and parent metal shall be determined by the point counting method detailed in A standard 25 points grid will be applied at a 400X, magnification for

the weld and 700X minimum for the Heat Affected Zone (HAZ).

Cross referencing to be carried out by the same electromagnetic measurement devise (EMD) planned for use on production welds. A ferrite count will be carried out on production welds to verify the % ferrite within the control limits set in the Welding Procedure Specification (WPS) and Procedure Qualification Record (PQR). Production ferrite testing should be performed ideally with a Fischer Feritscope or equivalent EMD that can measure both FN (ferrite numbers) and % ferrite. The production testing is to be performed at intervals of 3 tests every 5 feet of weld; one in each of the base metal and weld. Whereas the acceptable range for ferrite is 35 to 55%, preferably at the lower side of this range, all single point measurements should be within the range specified on the PQR. [Note: We reported in PWL#119, section 3, on a study that questioned the interlaboratory correlation of results obtained by metallographic methods, and recommended that "Ferrite requirements for weld metals should be based as much as possible upon measurement of FN by instruments calibrated according to the ISO 8249 or AWS A4.2 standards".

Presence of Intermetallic Phases or precipitates in welds: ASTM A923 (see above), Method B or C. Austenite Spacing: For sub-sea applications, all fabrication techniques that tend to decrease austenite spacing (free ferrite path) are favoured to ensure resistance to HISC (Hydrogen Induced Stress Corrosion) cracks. Corrosion Testing: ASTM G48 - 11 Hardness Survey: Depending on the DSS (Duplex Stainless Steel) grade and service environment. A Vickers hardness traverse averaging HV(10) 310, with no individual reading exceeding 320HV. For conversion of units refer to API 938C, figure 2. In production, hardness traverse should sample the HAZ and the weld metal. Hardness conversions to be referenced from API-938C, figure 2. For sour service hardness values should comply with NACE MR0175 Impact Testing: Depending on Minimum Design Temperature and engineering recommendations, 45J average @ -46°C. according to ASTM A923 (see above), method B. Test quantities shall be as per Table B.1, Appendix B of API technical report 938-C. Good impact test results are also a good indication of a successful welding procedure. A production test plate for impact testing is good practice. Associated with the minimum design temperatures and engineering recommendations, minimum CVN (Charpy V-notch Number, the output of a Charpy impact test) of the parent and weld metal should be 45J @ -46°C as per ASTM A923 method B. PMI: Positive Material Identification either by X-ray Fluorescence (XRF) or by Optical Emission Spectroscopy (OES) to be carried out on all production welds. The report should include Cr, Mo, Si, W, Ti, Nb, C, O, N Ni, Mn and Cu. A good description of these 2 PMI procedures is available at

3 - How to do it well: Aluminum Welding Safety Tips

While safety practices risk to be dismissed and neglected by busy welders, it is essential that they be studied and rehearsed at regular intervals by all involved, and be enforced by management. This is important both at the single individual level, for the responsibility one has for proper self well being (including one's family) and at the working place, where accidents should not be tolerated. An Article titled as this note was published at page 34 of the September 2013 issue of the Welding Journal. It should be studied thoroughly by all involved, by dedicating sufficient attention to each precaution and by translating each recommendation in action items to be implemented as required. The article singles out specific considerations affecting aluminum welding. In particular the following areas are dealt with in detail: Hot Metal Burns, Electrical Shock and Radiated Light. To avoid the described painful consequences of these hazards, one should be aware of the dangers of careless behavior, and one should make a habit of using the prescribed personal protective equipment. Additional factors to keep in mind are excessive Noise, Fume Emissions, Cleaning Fluids and Explosions, to be taken care of with suitable attention. Serious reading of the original article in the magazine quoted above is recommended to all involved with aluminum welding. Safety in the workplace is imperative. Precautions are never excessive. Avoidable accidents should never occur. 4 - Filler Metal Care for Hydrogen Control

An Article published at page 82 in the September 2013 issue of the Welding Journal summarizes the risks posed by hydrogen finding its way in the weld pool, especially in high strength steels. A short introduction reminds of the destructive dangers looming on welding production, if inadequate care is exerted to prevent absorption of this light gas in the molten metal, where it can easily diffuse. Five practical steps are then suggested to implement methods to control hydrogen diffusion in the welding process. The first, to minimize joint stress, is a requirement of any good design, and beyond the reach of the welder. Anyhow a diligent welder who remembers past successes and failures may be able to provide useful hints to a careless engineer who overlooked dangerous details. The second is the reminder of the importance of careful application of well conceived welding procedures, with reference to adequate thermal cycles before and after welding. The third, considering the selection of suitable filler metals, may be imposed on the welder from above, even by an over conscious purchasing agent willing to spare a few pennies in consumables. The recommendations of an experienced welder may be invaluable to the organization, if due attention is paid to the consequences of improper selection. Suitable storing and handling of filler metal is certainly in the welder's hands and under his/her responsibility. Prevention of moisture absorbency is of utmost importance, as good welders should know. The application of baking cycles should be thorough and adequate, not too difficult to take care of. Assuring suitable condition of consumable packaging at all times should become most natural to all. Making sure that anyone involved in fabrication is aware of the catastrophic consequences of hydrogen induced cracking, can be a necessary condition to take always utmost care of hydrogen prevention in all phases of welding. Readers are invited to seek and read the original article mentioned above. See also our page on Hydrogen Embrittlement. 5 - Online Press: recent Welding related Articles Laser hybrid welding: Powerful factory floor process Laser Spectroscopy Overcomes Measurement Challenge Plastic Bench Welder utilizes directed infrared system Bay Bridge: Weld inspection and repairs ongoing in tower base Engaging the workforce of the future in the skills-gap era

6 - Terms and Definitions Reminder Infrared radiation is that part of the electromagnetic energy spectrum with wavelengh between 770 and 12000 nanometers. Laser beam oxygen cutting is a variation using heat from a laser beam to cut metal. Oxygen arc cutting is a process that uses an arc between the workpiece and a consumable tubular electrode through which oxygen is blown to the workpiece to cut into the metal. Pulse time in resistance welding is the duration of a current pulse. Root pass is a weld pass made to produce a root bead. Synchronous timing in resistance welding, is the initiation of each half cycle of welding transformer primary current on an accurately timed delay relative tothe polarity reversal of the powewr supply. Thermite mold is formed around the workpiece joint to receive and shape the molten metal. Workpiece lead is the electrical conductor between the welding current source and the workpiece connection. 7 - Article: Integrated Computational Materials Engineering (ICME)

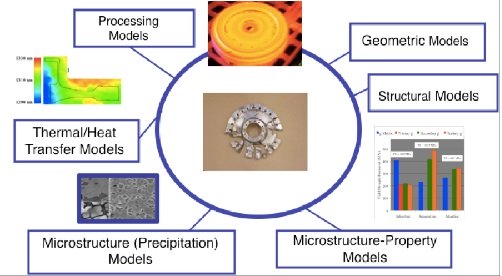

Technological Experience is an important asset developed through a long and successful professional career. Those who were determined to achieve a substantial level of competency in their field are rightfully recognized as fundamental pillars in their organizations and enjoy the coveted status of mentors and leaders. In times of accelerated development however, it is essential to recognize that new techniques become available. Managers and Engineers should be alerted that significant progress has been achieved quite recently in a branch of Materials Engineering relying heavily on recently developed Computational methods. While the practical applications are quite specialized and require long and thorough preparation to learn and use the new tools available, the decisions to dedicate efforts toward specific applications rest with informed managers who should know which advantages could be reaped by developing suitable complex problem solving routines. Two articles published in the September issue of Advanced Materials and Progress, an ASM International magazine, highlight some of the uses and results recently implemented. At page 17 the first article explains how this versatile tool is instrumental in drastically reducing the development time of new materials for aerospace applications. By using ICME tools these new alloys are obtained not only faster, but also can be designed much more inexpensively, to meet specific property targets such as strength, toughness, corrosion resistance, and others. ICME computational tools help tap the resources of materials science, applied mechanics, quantum physics, and advanced properties modeling using extensive thermodynamic and kinetic databases. Property targets are established in the design stage by specifying and developing precise chemical composition and processing parameters. Using grants and support generated by specific US government initiatives to promote projects, originating by several Departments and Science Research institutions, a private company undertook to develop entirely new alloys to solve serious materials-related problems. The article describes, without much detail, how proprietary thermodynamic and kinetic databases provide the data that feed into precipitation prediction and microstructural evolution models. These are used to adjust chemistry and thermal processing parameters that help predict equilibrium phases needed to provide the sought properties. Obviously the initial specifications must be fine-tuned by practical experimentation, but the outcome is generally improved performance at much reduced development costs. The article lists several different new alloys developed to achieve specific target requirements, in particular four ultrahigh performance steels. The time span of five to eight years from development to production and field testing is considered a remarkable achievement. Given the proven successes realized by using ICME in the last 15 years, there is well founded expectation that the future integrated computational design of novel materials will impact industry, as both demand and successful implementation of advanced ICME-designed alloys grows.

The following book may provide essential information:

Integrated Computational Materials Engineering (ICME) for

Metals: Author(s): Mark F. Horstemeyer Available from:

The second article on page 55 is titled It illustrates how the use of advanced computational tools enables accurate simulation of gear heat treatment to predict phase transformation kinetics and distortion. The article refers to general disciplines [Computational fluid dynamics (CFD), Computer-aided engineering (CAE), Finite Elements Analysis (FEA), Noise, vibration, and harshness (NVH)] and to specific proprietary software programs [The Abaqus (Dassault Systèmes) FEA model and DANTE (Deformation Control Technology Inc.) microstructure model]. It explains how the need to predict heat transfer during high pressure gas quenching and to couple it with phase transformation distortion analysis, led to the development of a special Computational program, called ICME-GearHT. The capability of this model, that incorporates even latent heat release due to phase transformation, was validated using experimental data. This tool enables accurate simulation of the transmission gear heat-treatment process, predicts phase transformation kinetics and distortion, and provides cost-effective, time-efficient evaluation of new gear designs. Practical experimentation including temperature measurements at different fan speeds permits to validate the model predictions with actual results. The model was used to evaluate properties of furnace-fixture materials, chamber configurations, and parts loading in the furnace. Distortion calculations are compared with experimental results. The model can be used to identify the best effective heat treatment solutions for minimized distortion and to provide guidelines for process design and optimization. Recent experimental studies have shown that use of carbon-fiber composite (CFC) fixtures reduces distortion by 25%, and by 50% if combined with step quench. Readers involved with research of improved materials for special applications or with gear deformation problems following heat treatment might consider looking deeper into the issues described to benefit from these advanced technological development. All readers are invited to seek the quoted articles.

Note: A new Mid Month Bulletin was recently issued, providing Online Links to authoritative Internet Sources that published articles and information on:

It is available by clicking on Bulletin 90. Interested readers wishing to learn the subject in more depth are advised to download this publication. 8 - Site Updating: Friction Welding Processes (R), Friction Stir Welding Equipment (R) The two reviewed and updated Pages of this Month in our website (www.welding-advisers.com) deal with related processes. The first page concentrates on friction processes, which were developed also for unique repair applications of costly items like the main shaft of gas turbine engines. The revised and updated page is found at Friction Welding Processes. The other page gives a short story with references of the innovative process which enjoyed successful applications in most demanding fields like aerospace. Readers can browse the Site Map for main subject pages, the Welding Topics page for the titles of main PWL Articles, and the Welding Resources page for lists of Online Links to rich sources of knowledge. Comments, questions and feedback are welcomed. Use the Contact Us Form. 9 - Short Items

9.1 - Abrasive Wear is the removal of material from a surface by hard particles sliding or rolling across the surface under pressure. 9.2 - Ball Milling is a method of grinding and mixing material, with or without liquid, in a rotating cylinder or conical mill partially filled with grinding media such as balls or pebbles. 9.3 - Canning is enclosing a highly reactive metal preform within a can of relatively inert material for the purpose of hot working without undue oxidation of the active metal. 9.4 - Deep Drawing is forming deeply recessed parts by forcing sheet metal to undergo plastic flow between punch and dies, usually without substantial thinning of the sheet. 9.5 - Electrochemical Reaction is caused by passage of an electric current through a medium that contains mobile ions (as in electrolysis); or, a spontaneous reaction made to cause current to flow in a conductor external to this medium (as in a galvanic cell). In either event, electrical connection is made to the external portion of the circuit via a pair of electrodes. 9.6 - File Hardness is determined by the use of a steel file of standardized hardness on the assumption that a material that cannot be cut with the file is as hard as, or harder than, the file. Files covering a range of hardnesses may be employed; the most common are files heat treated to approximately 67 to 70 HRC.

10 - Explorations: beyond the Welder Scientists Deploy Underwater Observatory to Track Warming, Acidification New Technology Allows Better Extreme Weather Forecasts 400 PPM: Can Artificial Trees Help Pull CO2 from the Air? 5 Techniques for Maintaining Web Confidentiality Kepler Space Telescope's Broken Wheel Could Aid Stellar Physics 11 - Contributions: Welding Remote Control for Improved Safety

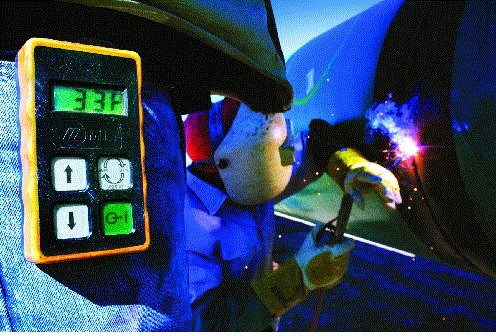

An article published in the September 2013 issue of the Welding Journal at page 44, makes the point that implementing remote control for welding equipment has distinctive advantages. Wireless commands permit continuous control of welding parameters and shutoff switch operation without leaving the weld location, while eliminating additional cords and control cables cluttering the working space. In construction places power sources may be quite far from the welder. Remote controls avoid needless displacements of welders, involving danger of falls, while removing the control cable tripping hazard. Such controls are available for SMAW (Shielded Metal Arc Welding) and GTAW (Gas Tungsten Arc Welding) as well as for GMAW (Gas Metal Arc Welding) and FCAW (Flux Cored Arc Welding). Wireless remote controls typically operate within line of sight between command and power source. Other remote controls relate signals through the welding cables, eliminating additional control cables, and solving the line of sight issue. As many job sites have multiple power sources in one area, full control tracks cables back to the correct power source eliminating possible errors, and it helps improve productivity and quality. Error messages can be transmitted, alerting the welder of incorrect polarity. Information to be transmitted back and forth includes the same details available on the power source itself and on the wire feeder. Processes controllable from a distance include modified short circuit GMAW and Pulsed GMAW. Full remote control capabilities, process selection, material type, and wire diameter, gas type, wire feed speed, and voltage need connection of the power source with a specially designed "smart" wire feeder. This type assures that the waveform selected extends to the point of use in an optimal state because it is only traveling the length of the GMAW torch cable. Safety, productivity and quality are powerful incentives recommending the adoption of this advanced remote control welding technology wherever the sheer number of power sources active at the same time in the same place may be cause for confusion and errors. Readers are urged to seek the original article in the magazine pointed at above.

12 - Testimonials Name: Samir Kumar SenGupta Thank you very much for knowledge enrichment. Samir Kumar SenGupta

Name: Paul Ipolito Thank you for the very informative article on duplex stainless steels. Paul Ipolito 13 - Correspondence: a few Comments 13.1 - One more example of a preposterous query: Date: 12 Sep 2013 "I want to know welding method, edge preparation, voltage, current for metal arc welding" Could anyone find a better example of a query whose enquirer has no idea of the subject? 13.2 - An unfortunately recurring pattern: A reader sends a question. 14 - Bulletin Board 14.1 - Materials Science & Technology 2013 (MS&T’13) 14.2 - FABTECH 2013 Including: 14.3 - FABTECH India colocated with Weld India.

If you think that this page might be useful, you are invited to forward it to a Friend. Practical HARDNESS TESTING made simple. If you want to contribute from your thoughts and experience visit our new page reachable by clicking on Welding Talk and typing or copying directly in the form.

Here are some short testimonials from real SBI! customers whose lives have been changed by SBI!. Anyone with self confidence can take the test and mess around with SBI! for three months at no cost and at no risk. Visit this page: http://buildit.sitesell.com/Quark.html

"SBIers just "get it." They are too busy building their web business to worry about "how it all happens" and are full of enthusiasm and ideas. It's contagious to watch everyone working and moving ahead."

Fiona McCardle/Jim Andrew

Rent a Villa in Tuscany

http://case-studies.sitesell.com/Quark.html#LEADGEN

BUILT BY: Click on this Logo NOW!

Copyright (©) 2013, by Elia E. Levi and

See you next time...

|

||||||||||||

| Back to Back Issues Page |