| Back to Back Issues Page | |||||||||||

|

|||||||||||

|

PWL#123 - Computer Modeling in NDE, Aluminum Tubing Brazing Overlap, Proceedings from the 5th IBSC November 01, 2013 |

|||||||||||

| We hope you will find this Letter interesting and useful. Let us know what you think of it.

PWL#123 Computer Modeling solving Problems in NDE, Aluminum Tubing Brazing Overlap, Proceedings from the 5th International Brazing and Soldering Conference, Changes in the 2013 Edition of ASME BPVC, Section IX, Aerospace Materials Competition between CFRP+Titanium and New Aluminum Alloys, Revised Website pages on Fume Hazards (R) and Heat Treatment (R) and much more...

November 2013 - Practical Welding Letter - Issue No.123

The Mid October 2013 Issue of Practical Welding Letter, Bulletin 90, introducing Online Resources on Integrated Computational Materials Engineering was NOT distributed by e-mail.

DON'T USE REPLY to send your messages! Use the Contact Us form instead.

You are urged to pass-along this publication to your friends, if you like it, and if you think it may help them. If you received this from a friend and if you like what you read, please subscribe free of charge and you will also receive a bonus book on Practical HARDNESS TESTING Made Simple. The addresses reported hereafter were live and correct at the time of their publication. There is no guarantee that they will always be so, because they are administered by the sources themselves and are under their control. Note: References to articles or other documents are given here in If they are URL's (Uniform Resource Locator), which is the analogue of an address, they begin with "http://..." or "www.". These are not live and must be copied and pasted entirely into the browser (after having been selected with the mouse or otherwise). If they are long they may be displayed in two or more lines. In that case one has to care that the URL be copied completely in a single line without any space, and Enter. If the information is important to you as we hope, you may save the selected pages in a suitable folder on your Computer for easy reference. You are welcome to forward this page to those of your friends who may profit of this information.

(Sponsored Links)

1 - Introduction 2 - Article - Computer Modeling 3 - How to do it well: brazing overlap 4 - Advancements in Filler Metal for Brazing and Soldering 5 - Online Press: recent Welding related Articles 6 - Terms and Definitions Reminder 7 - Article: Changes in the 2013 Edition of ASME BPVC, Section IX 8 - Site Updating: Fume Hazards (R), Heat Treating (R) 9 - Short Items 10 - Explorations: beyond the Welder 11 - Contributions: Aerospace Materials Competition 12 - Testimonials 13 - Correspondence: a few Comments 14 - Bulletin Board

2 - Article - Computer Modeling

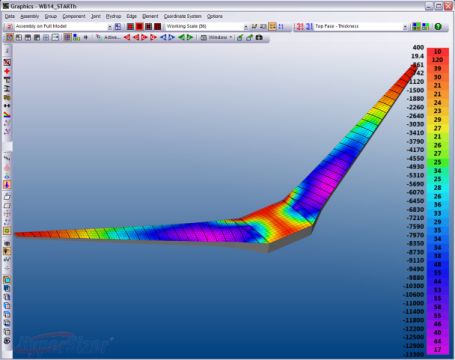

The trend of enlarging the scope and deepening the reach of computational tool development for advancing materials engineering and manufacturing capabilities, exposed in the last issues of PWL (PWL#122 and Bulletin 90), appears also from other sources that work on different applications. The October 2013 Issue of AM&P, a publication of ASM International, mentions at page 10 the combined efforts of two university researchers that, with the help of a grant obtained from the National Science Foundation, will join forces for developing computing systems in support of material activities and computational models based on geometry, materials, and physics. "The next step is to create models and languages that include information about the materials, physics, and design intent. The scope of the grant is to create an abstract, foundational link between computers and materials and their behaviors. If successful, this research should lead to a systematic reexamination of how design and manufacturing are taught and practiced at all levels". At page 18 an article explains how "Computer Modeling Solves Practical Problems in NDE" (Nondestructive Examination) by offering examples of work in Ultrasonic Testing (UT) and in Eddy Current (EC) inspection. Modeling can be helpful in the fast evaluation of sensor response to various inspection parameters, determining its impact on procedure performance. Fine details in the manufacturing and finishing of sensitive probes or sensors can be significant in the response of devices to actual inspection conditions: modeling studies aim to identify possible ways of sensor and inspection technique optimization. The article goes on by giving detailed description of typical instances where the proper use of modeling provided insight that helped substantially in solving the problems. It concludes that the use of modeling tools in NDE development and evaluation process brings about numerous potential benefits, mainly time and cost savings. Modeling reduces significantly the time required to optimize procedures used to inspect structures with complex geometries. The number of experimental specimens and mock-ups needed for technique and procedure validation is remarkably reduced, providing substantial cost savings, while increasing also inspection reliability and repeatability. Another article, at page 22 of the same issue outlines the challenges confronting designers of modern airframe, especially where composite materials are used. This is because there are still barriers to innovation even with the most advanced CAD (Computer Aided Design) and FEA (Finite Elements Analysis) software. Optimization tools are not yet as integrated as they should be, and procedures are needed to enable a faster design cycle. Nevertheless new software programs developed at NASA, that offer design, analysis, and optimization tools for both composites and metals, help to advance development by automating data exchanges without loss of information. By using the software during preliminary design, engineers can explore more options and perform tradeoff studies involving thousands of alternatives. This enables validation of strength and minimal weights for each option, to explore the greatest overall weight savings and multiple opportunities to reduce cost. The article concludes that "As the commercial aircraft and aerospace industries continue to embrace composites and other advanced materials in search of lightweight structures, new challenges are on the horizon. Solutions will emerge from optimization modeling that can address every variable, identify substantial weight savings, and generate several alternative designs. Doing all of this seamlessly and without disrupting existing processes will help engineering teams achieve the best results possible. In an ideal airframe design process, wide-open design space exploration will lead to lightweight, structurally sound designs that are easily manufactured and certified to fly". Readers are urged to seek the original articles in the publication referred to above.

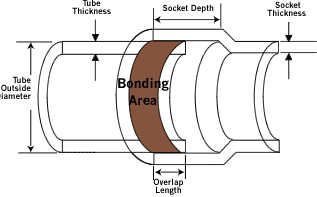

3 - How to do it well: brazing overlap Brazing aluminum alloy tubing joints, where the smaller diameter tube is inserted for some overlapping length into the larger diameter one, requires that two geometric parameters, overlap length and clearance at brazing temperature, be correctly established by design. As a rule, the overlap length should be as short as possible, compatible with sufficient strength in a simple tensile test. In practice, for aluminum alloys, the acceptable length should be between one and three times the thickness of the thinnest member. This is less than what is acceptable for brazing other materials. If possible, brazing filler metal should be preplaced at the inside end of the joint and made to flow toward the free end, where the result of the operation could be easily inspected. It should never be supplied from both sides. Clearance at the brazing temperature should be minimal, between 0.05 and 0.1 mm (0.002" - 0.004"), as shear strength drops rapidly with the thickness of the brazing material in the joint.

4 - Advancements in Filler Metal for Brazing and Soldering The Proceedings from the 5th International Brazing and Soldering Conference on April 22-25, 2012 in Las Vegas, Nevada, USA (IBSC 2012) are available. The contents (11 pages) of the proceedings are downloadable from By viewing the Table of Content, readers can find out the articles that could provide information on their applications. In that case they may read those pages from the following reference. Selected pages can be viewed from Filler Metal Properties Symposium, includes 6 papers and is part of IBSC 2012, Sponsored by ASM International and American Welding Society.

5 - Online Press: recent Welding related Articles Laser welding leads to Corvette's strength, refinement and quality EWI gets $5M slice of innovation funding pool for research project The Future of Welding - Laser Hybrid Welding HIGH-SPEED IMAGING: Sunnybrook Welding innovation helps farmers save time, money and fuel Laser welding of composites meeting draws a crowd

6 - Terms and Definitions Reminder Intermediate weld bead results from the deposition of an intermediate weld pass. Longitudinal bend test specimen is a weld test specimen welded along its axis, presented to the bend testing fixture in such a way that the bend axis be transversal to the weld. Molten metal, same as weld metal. Powder Flame Spraying is a process variation where the surfacing material is in powder form. Reaction Stress is generated by thermo mechanical deformations when the member is connected to other parts of the structure. It would not exist if the member were an isolated free body. Stress relief heat treatment means heating uniformly a stressed structure or a part of it to a suitable temperature for relieving most of residual stresses, followed by uniform cooling. Throat crack appears on the surface of a fillet weld. Weld Crack is located in the weld metal or in the heat affected zone.

7 - Article: Changes in the 2013 Edition of ASME BPVC, Section IX

An article by Walter J. Sperko, published at page 87 of the October 2013 issue of the Welding Journal, summarizes the significant changes that become mandatory with the new year. All of the changes can be readily identified in the "Summary of Changes" found in the new edition of Section IX. The original article referred to here, may help readers who have only occasional interaction with the said Code, to find out how the new document now organizes basic requirements. The introduction of two new Parts: QG General Requirements, and QF Plastic Fusing is the big change in Section IX 2013. Part QG is an extract of the general and administrative requirements found in the previous Parts dealing with Welding and Brazing, established to avoid repetitions, by instructing to refer to the process in cause, as required. The article explains that the new QG-101, Procedure Specification, specifies the requirements for the written instruction document, with no significant changes, except that "manufacturer or contractor" is now substituted by "organization". It also point out that, while specific requirements have been relocated in the new Part QG, the administrative rules were not changed, so that any practices that were acceptable or prohibited under the previous editions of Section IX are acceptable or prohibited in this edition. A new Appendix K has been introduced to give guidance to other standards developers and engineers who want to invoke the requirements of Section IX, on the proper way to do so. Part QF establishes the present rules for Plastic Fusing processes: by now it covers only hot plate fusion of high-density polyethylene (HDPE), but its open structure allows future additions. It has four Articles that parallel the organization of Parts QW and QB. Three new welding processes have been added in Welding Procedure (QW-200): Hybrid plasma-GMAW, hybrid laser-GMAW and Friction stir welding. To preclude the current interpretation that, in a 10-in. (250-mm-) thick test coupon only depositing ¾ in. (19 mm) of weld metal with a single welding process, without welding the full thickness of the test coupon would qualify for the whole thickness, a note has been added to QW-451 specifying that test coupons more than 6 in. (150 mm) must be welded for their full thickness. A note has been added to QW-451.4 pointing out that fillet welds qualified by groove weld test are subject to restrictions imposed by supplementary essential variables when qualification of the WPS with impact testing is a requirement. The Article reviews the rules in QW-462.1(d), for accepting machined specimens violating machining tolerances, provided the actual diameter (instead of the nominal) is used to calculate the area of the specimen section. Additional specifications refer to hardness testing requirements, to metal overlay qualification and to welder qualification changes. A correction of conflicting instructions relative to current tolerance in stud welding has been resolved. Information on changes relative to base and filler metals should be looked for in the original article or in the new 2013 Code because of the risk of introducing errors by incomplete summary. The article encourages readers to check published interpretations that can be found at:

These were issued under IX-13-03. To seek the white paper Auditing Welding under ASME Section IX one should do a Web search for the paper by its title. The article referred to above is recommended to all.

8 - Site Updating: Fume Hazards (R), Heat Treating (R) The Pages of this Month that were revised and updated in our website refer to subjects quite important for every welding operation. On the subject of Fume Hazards, every welder should know what means must be used to avoid dangers to the personal health of those involved. Managers should instruct their welders on the long term damages likely to affect those who don't apply the required precautions. They should provide welding fume extractors and care that they be well maintained and in good working condition. Their use should be always enforced. Heat Treating is a most comprehensive term. Very often some kind of it must be applied, before, during or after welding. It is imperative that welders know the means for performing these operations and how they should be applied to achieve their purpose. Readers can browse the Site Map for finding main subject pages, the Welding Topics page for the titles of main PWL Articles, and the Welding Resources page for lists of Online Links to rich sources of knowledge. Comments, questions and feedback are welcome. Use the Contact Us Form. 9 - Short Items

9.1 - Abrasive Jet Machining consists in material removal from a workpiece by impingement of fine abrasive particles that are entrained in a focused, high-velocity liquid or gas stream. Similar to Abrasive (water)jet cutting. 9.2 - Back Draft is a reverse taper on a casting pattern or a forging die that prevents the pattern or forged stock from being removed from the cavity, unless it is built with special provisions to permit removal. 9.3 - Carbon Steel is that having no specified minimum quantity for any alloying element (other than those commonly accepted) and containing only an incidental amount (less than 0.5%) of any other element. Low-carbon steels contain up to 0.30% C, medium-carbon steels contain from 0.30 to 0.60% C, and high-carbon steels contain from 0.60 to 1.00% C. 9.4 - Deep Etching refers to macroetching for metallographic examination, especially for steels, to determine the overall character of the material, and the presence of imperfections, such as seams, forging bursts, shrinkage-void remnants, cracks, and coring. 9.5 - Emission Spectroscopy is the branch of spectroscopy treating the theory, interpretation, and application of spectra originating in the emission of electromagnetic radiation by atoms, ions, radicals, and molecules. 9.6 - Gutter is a depression around the periphery of a forging die impression that allows space for the excess metal. It surrounds the finishing impression and provides room for the excess metal used to ensure a sound forging. 10 - Explorations: beyond the Welder Business Aims to Replace Diesel as Fuel for Trucking Search Escalates for Key to Why Matter Exists also How Electric Vehicles Play a Key Role in the Grid of the Future Why Australia's Wildfires Are So Extensive Now Threats to Sharks Destabilize Entire Ecosystems

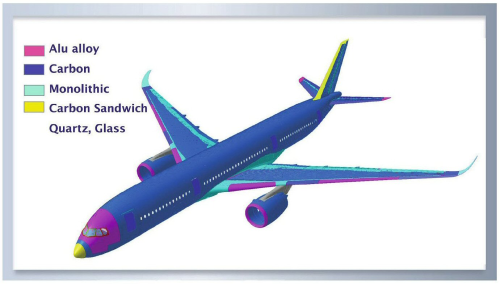

11 - Contributions: Aerospace Materials Competition Recent publications outline the success of Carbon Fiber Reinforced Polymers (CFRP) for building load sustaining airframe parts, mainly for its high strength-to-weight ratio and rigidity. It has been established that these materials have good compatibility with Titanium alloys, as their stiffness and coefficient of thermal expansion are similar. Furthermore Titanium is electrochemically compatible with CFRP and resists galvanic corrosion. That cannot be said of aluminum alloys which tend to corrode when placed in contact with CFRP. The design of new generation of large passenger aircraft, the A380 and A350 from Airbus and 787 from Boeing, use greater volumes of CFRPs in the airframe. Concurrently a larger consumption of Titanium alloy parts is projected for the near future, to be met by an increase in the estimated metal production. Reacting to these developments, aluminum producers have invested heavily in research to find ways to combat corrosion and promote lighter alloys containing Lithium to be joined successfully to CFRP structures. The competition is assured to advance the understanding of the basic engineering issues so that each application will benefit of optimized solutions. The results of the researches will be compiled in the databases to be used with the new software being developed as mentioned in the last article reviewed in section 2 above. Read the last article pointed at in section 5 above and also: Titanium Producers Positioned for Growing Demand Aluminum Fights Back!

12 - Testimonials On Tue Oct 01 14:42:08 2013, the following results were submitted from the Name: Paul Ipolito Kindest regards

On Mon Oct 28 14:35:04 2013, the following results were submitted from the Name: Eric Hild I own a tool welding shop. I use your website as an information source I have your page bookmarked and I look at it often. It is one of the few (if only) Eric

13 - Correspondence: a few Comments 13.1 - This is not the first time that an inquirer sends a void message. He does not ask for any information. Therefore I am relieved from the task of writing an answer. But can someone explain me what is the purpose? 13.2 - A reader asked: Could you please give a suggestion [...]. Unfortunately I could not, because essential details were missing. 13.3 - Should I insist that inquirers follow a rigid format for asking questions, that would make sure that all key details are included? The sloppiness of asking is appalling. 14 - Bulletin Board 14.1 - International Symposium for Testing and Failure Analysis 14.2 - Introduction to Friction Stir Welding. 14.3 - Hypertherm Cutting Institute Online.

BUILT BY: Click on this Logo NOW!

Copyright (©) 2013, by Elia E. Levi and

See you next time...

|

|||||||||||

| Back to Back Issues Page |