| Back to Back Issues Page | ||||||||||||

|

||||||||||||

|

PWL#137,GMAW Efficiency, Weld Tasking & Quality Monitoring, Brazing copper,New SAW Technology,Impact January 05, 2015 |

||||||||||||

| We hope you will find this Letter interesting and useful. Let us know what you think of it.

PWL#137 Improving GMAW Efficiency by studying gas properties, using software for Weld Task Assigning & Quality Monitoring, Brazing copper problem and solution, a new development in SAW Technology, Maintenance-Welding-Tips (NEW) and Updated Resources (NEW) on Hybrid Laser Arc Welding, NDT to assess Mechanical Performance Loss In Impact-Damaged Composites and much more...

January 2015 - Practical Welding Letter - Issue No.137

Important NoticeThe Mid December 2014 Issue of Practical Welding Letter, Bulletin 103, dealing with Updated Resources (NEW) on Hybrid Laser Arc Welding was not distributed by e-mail but it is available at Bulletin 103 and from the updated Welding Resources Page.

DON'T USE REPLY to send your messages! Use the Contact Us form instead.

You are urged to pass-along this publication to your friends, if you like it, and if you think they may enjoy it. If you received this from a friend and if you like what you read, please subscribe free of charge and you will also receive a bonus book on Practical HARDNESS TESTING Made Simple. The addresses reported hereafter were live and correct at the time of their publication. There is no guarantee that they will always be so, because they are administered by the sources themselves and are under their control. Note: References to articles or other documents are given here in one of two forms. If they are URL's (Uniform Resource Locator), which is the analogue of an address, they begin with "http://..." or "www.". These are not live and must be copied and pasted entirely into the browser (after having selected them with the mouse or otherwise). If they are long they may be displayed in two or more lines. In that case one has to care that the URL be copied completely in a single line without any space, and Enter. If the information is important to you as we hope, you may save the selected pages in a suitable folder on your Computer for easy reference. You are welcome to forward this page to those of your friends who may profit of this information.

(Sponsored Links)

1 - Introduction 2 - Article - Improving GMAW Efficiency 3 - How to do it well: Weld Quality Monitoring 4 - Filler Metal for brazing a copper cable to a copper rivet 5 - Online Press: recent Welding related Articles 6 - Terms and Definitions Reminder 7 - Article: New SAW Technology 8 - Site Updating: Maintenance-Welding-Tips (NEW), and Updated Resources (NEW) on 9 - Short Items 10 - Explorations: beyond the Welder 11 - Contributions: Relating NDT Data To Mechanical Performance Loss In 12 - Testimonials 13 - Correspondence: a few Comments 14 - Bulletin Board

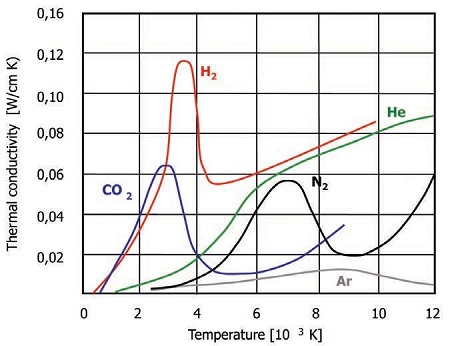

2 - Article - Improving GMAW Efficiency

If you think you know all you need to manage efficiently your current Gas Metal Arc Welding (GMAW) operations, well, you may be in for some surprises, when you read a recent article published on page 41 of the December 2014 issue of the Welding Journal. There may be room for substantial productivity improvement if you take into account the governing factors that influence the resulting outcome. The said article lists a long series of benefits, that sum up in improved quality and reduced costs, gained by thoughtfully selecting the recommended blending of argon-based, two components shielding gases. Among the different factors to consider are the ionization and dissociation energies of the gases, their thermal conductivity and the radial profile of the plasma arc, characterizing the energy transfer. The study reported checked two sets of welders employed each in welding a specific industrial product in one of two similar versions. All the data where automatically collected and then analyzed offline. If turned out that the largest expense was the consumable filler metal, at almost 70% of the total production cost. Also the shielding gas consumption was higher than the recommended, but leaks were suspected independent of welders discipline. The study detected unaccounted for parameter variability bringing to the conclusion that additional work is needed to reduce variation. Control in wire waste should be implemented. The authors conclude that understanding and establishing the actual weld costs involved and the factors that determine them are essential steps in the process of optimizing performance. This recommendation should be followed by all those responsible for the correct conduction of GMAW processes, with a view on improving productivity and assuring quality. Interested readers are urged to seek the above original article.

Thermal conductivity of different shielding gas components. [From the Welding Journal, December 2014, page 42]

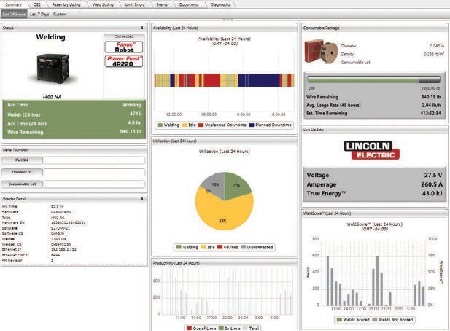

3 - How to do it well: Weld Quality Monitoring

It has been observed that certain welding production shops are perceived by management as too difficult to manage using the normal industry tools. Especially if one refuses to dedicate to the task the necessary resources. By being viewed as a craft, to be governed only by insiders, the sole source of knowledge, whole welding operations shun the normal checks and balances that any normal management would implement, and become the highest contributing factor to quality. An article, titled as this note, published at page 48 in the December issue of the Welding Journal, points out that new tools are now available for helping Management regain its say in production and quality monitoring. The tools described are those developed by a specific supplier. There in no reason to suppose that only these are available. Interested readers would probably gain knowledge and benefits by researching the solution best adapted to their own specific conditions. Two types of software aids are described.

The article outlines the benefits to be obtained by implementing both of the two complementary tools. Avoiding mistakes and improving quality was never before achieved so easily by any management. Readers are invited to explore the tools introduced by the Author, without that this publication takes parts, endorsing or recommending them. See the Power Wave Software Solutions page at leading you to the download of more specific pages, like the Search page for "Weld Sequencer™" wherefrom you may download the "Top 4 results" and then look for Lincoln’s Weld Sequencer™ CheckPoint™, a Lincoln Electric production monitoring software package Readers wishing to comment on these ideas are welcome to share their views.

CheckPoint™, a Lincoln Electric production monitoring software package, offers dashboard views of arc time, consumable usage, weld parameters for each weld, and other data. [From the Welding Journal, December 2014, page 50]

4 - Filler Metal for brazing a copper cable to a copper rivet

In the brazing Q&A section in the December issue of the Welding Journal at page 26, a reader inquires on a proper copper based brazing filler metal, to join a braided copper cable to a copper post/rivet. The problem arises because the flux used with the 95%Cd - 5%Ag is difficult if not impossible to clean, leaving a corrosive residue. The internal proposal to search a solder instead, was abandoned because of high temperature service conditions ruling out soldering. Due to the dangers in working with Cadmium, specifically avoided in the European Restriction of Hazardous Substances Directive (RoHS), the brazing expert, Tim Hirthe, suggests to look for a different filler metal. The inquirer's suggestion to investigate the applicability of aluminum fluxes is eventually ruled out because residual aluminum in the flux might cause galvanic cell corrosion (instead of chloride corrosion), not a favorable alternative. The final suggestion (after having ruled out Zn-Sn [zinc-tin] which might include Cd) is to go to low temperature Copper Phosphorus alloy (AWS BCuP), which, although melting at higher temperature, needs no flux for copper to copper brazing. I am always fascinated by the thoroughness of the analysis of these practical recommendations and I think that much more than a simple answer can be learned in the process. Readers are addressed to the original WJ article for finding there the complete discussion of the alternatives.

5 - Online Press: recent Welding related Articles Manufacturing Components for Welding Applications EWI Engineer Wins 2014 Elihu Thomson Resistance Welding Award KUKA Systems Develops Robotic Riveting System for Research and Markets: Global Welding Products Market 2014 - 2020 Ford F-150 plant notable for lack of noise, sparks

6 - Terms and Definitions Reminder Laser Beam Air Cutting (LBC-A) is a laser beam cutting process variation where the laser beam melts the workpiece and an air jet removes molten or vaporized material. MIG Welding is a nonstandard term for Flux Cored Arc Welding or Gas Metal Arc Welding. Oxynatural gas cutting (OFC-N) is an oxyfuel gas cutting process where natural gas is the fuel. Pulsed Gas Metal Arc Welding (GMAW-P) is a gas metal arc welding where current is pulsed. Resistance Welding Weld Time is the duration of current flow through the workpieces in making a weld by single impulse. Stick Electrode is a nonstandard term for covered electrode. Thermal Spray Deposit is the coating or layer of surfacing material applied by a thermal spraying process. Weld Metal Crack is that occurring in the weld metal zone.

7 - Article: New SAW Technology

This publication introduced, along the years, several updates on productivity improvements in Submerged Arc Welding. The last one, on SAW Optimization, appeared in PWL#134 in the October 2014 issue. A new fully developed SAW Technology is now introduced in an article published on page 46 in the December 2014 Issue of the Welding Journal. With the possible exception of those fortunate visitors of major Welding Conferences and Exhibitions, and of the dedicated habitual readers of WJ, there is possibly a large public not yet reached by this information. This cold electrode technology uses a special twin torch which, besides accommodating two filler wires in the same contact device, connected to the same power source and polarity, integrates a third, electrically insulated cold wire, between and parallel with the two hot wires, in the same device. The third wire speed is controlled independently from the other two. Its function is to absorb excess thermal energy and to increase the amount of deposited material without requiring additional heat. This permits to perform heavy welds with heat input below 76 kJ/in as demanded by ISO 15614 to satisfy impact toughness requirements for offshore applications. A specific industry using four such units is described. The major parameter used to evaluate productivity gain is weld deposition rate at the reported linear welding speeds. Remarkable increases are indicated, relative to regular twin SAW applications. While not intending to endorse or recommend the specific innovation described, we feel that interested readers may wish to explore for themselves if the advantages proposed might provide any benefits to their operations. Besides the article indicated above, readers may find a press release at From that same page a commercial brochure can be downloaded.

Welding head with two parallel hot wires and an electrically isolated middle cold wire.

8 - Site Updating: Maintenance-Welding-Tips (NEW), and Updated Resources(NEW) on Hybrid - Laser Arc Welding The new Pages of this Month cover thoroughly, possibly in a more useful way, subjects and operations that were already introduced in the past. Maintenance and Repair are important subjects that need to be confronted with open mind, without being unduly disturbed by the urgent need to put equipment back to work in the shortest time. In the new page a check list is introduced which may be helpful in trying not to forget essential considerations. A reference is provided to a logical decision model program, available from a renowned Handbook, that can be followed to build a repair plan. It is hoped that this new page might come in handy when in need of some assistance for dealing with emergencies. Read it by clicking on Maintenance-Welding-Tips. The other page, the Mid December 2014 - PWL#136B - Bulletin_103 with links to Updated Resources on Hybrid Laser Arc Welding, is available by clicking on Bulletin 103. We hope it might be useful to those using the Hybrid Laser Arc Welding Technology. If you need specific reference difficult to find out, please let us know and we will do our best to come up with useful answers. A large amount of information is freely available to anyone in the Welding Advisers website. One can review the Site Map and the Index Page to find what one looks for. One can also perform a search, by typing the requested terms in the box that appears in almost every page of the Welding Advisers website: the Results Page(s) will include also the articles of all issues of this Practical Welding Letter. Questions, comments and feedback are always welcomed. Don't use Reply, use the Contact Us form instead.

9 - Short Items

9.1 - Alloy Steel is an iron base metal containing specified quantities of alloying elements (other than carbon and the commonly accepted amounts of manganese, copper, silicon, sulfur, and phosphorus) within the limits recognized for constructional alloy steels, added to effect changes in mechanical or physical properties, generally following well defined heat treatment cycles. 9.2 - Bearing Test is a method of determining the response to stress (load) of sheet products that are subjected to riveting, bolting, or a similar fastening procedure. The purpose of the test is to determine the bearing strength of the material and to measure the bearing stress versus the deformation of the hole created by a pin or rod of circular cross section that pierces the sheet perpendicular to the surface. 9.3 - Compaction is forcing particulate or granular material together (consolidation) under pressure or impact to yield a relatively dense mass or formed object. In powder metallurgy, the preparation of a compact or object produced by the compression of a powder, generally while confined in a die, with or without the inclusion of lubricants, binders, and so forth. With or without the concurrent applications of heat. 9.4 - Degradation is a deleterious change in the chemical structure, physical properties, or appearance of a material. May be due to an uncontrolled treatment or to changing service conditions. 9.5 - Extractive Metallurgy is the branch of process metallurgy dealing with the winning of metals from their ores. 9.6 - Fold is a defect in metal, usually on or near the surface, caused by continued fabrication of overlapping surfaces. A forging defect caused by folding metal back onto its own surface during its flow in the die cavity.

10 - Explorations: beyond the Welder First Maps from Carbon-Monitoring Satellite Show Global CO2 Levels Could Extinct Clouded Leopards Be Reintroduced in Taiwan? NASA Rover Finds Mysterious Methane Emissions on Mars How Lithium Ion Batteries Grounded the Dreamliner The Dark Corners of Our DNA Hold Clues about Disease

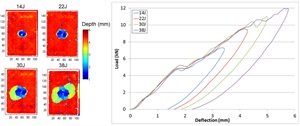

11 - Contributions: Relating NDT Data To Mechanical Performance Loss In Impact-Damaged Composites The ability of predicting the residual useful life of structural fabrications is essential to guarantee economic continuing operation of critical life-affecting constructions. Although the specific methodology used to plan and investigate the monitoring of useful life left in a composite construction, may be remote from the pressing needs of welding professionals, it seems important to be open to accept new concepts which might help one in unexpected ways. While the knowledge and practice of periodical monitoring of the integrity of metallic manufactured structures are standing on solid (Fracture Mechanics) bases, the same cannot be affirmed regarding increasing numbers of composite materials objects. Therefore studies were initiated by the Welding Institute (TWI), managing with partners a joint industry project to try to correlate the results of nondestructive tests with numerical simulations of compression-after-impact (CAI) failure in uni-directional, carbon fiber-reinforced plastic (CFRP) composites, previously impact damaged specimens. The paper reported hereafter explains in its introduction that there is currently no accepted method of incorporating non-destructive test data, gained from inspection of impact damaged composite directly into finite element models capable of predicting mechanical performance. It then describes the composite tested and provides its original mechanical properties. Impact loading damage was then inflicted on selected specimens with different energy blows, within a testing machine designed to provide measurable and repeatable impacts. The resulting impact damage was assessed using ultrasonic testing (UT) for all panels and computed tomography (CT) was undertaken on four panels containing damage from each impact energy for validation purposes. The paper explains how the UT results were interpreted and analyzed, and how the delamination patterns were detected and recorded. A finite element model was prepared for evaluating the residual life of each one of the specimens with internal damage. A delamination prediction was elaborated for each interface, and incorporated into the simulation. The simulation was used to predict the failure mode within the load parameter selected for stressing the specimens. The specimens, mounted in a special fixture, were tested to failure in the proper conditions. For each test, strain stress and load were recorded in real time. Within the initial assumptions of the project, the study succeeded in predicting the CAI (residual) strength and in indicating that the buckling modes inducing final collapse are well predicted. Interested readers are urged to seek the original paper at the link indicated hereafter. Relating NDT Data To Mechanical Performance Loss In Impact-Damaged Composites

[From the above TWI Paper]

12 - Testimonials On Tue Dec 09 07:57:11 2014, the following results were submitted from the

"Form 5" on welding-advisers.com: Name: Alexander Barth Hi Elia, Kind regards

On Thu Dec 18 12:13:57 2014, the following results were submitted from the

"Form 5" on welding-advisers.com: Thanks so much, I hope to hear back from you.

13 - Correspondence: a few Comments I got a message of a Reader with specific experience in a certain welding sector, proposing to write for this publication an article on current technologies and future developments. I was delighted by such an offer and accepted it immediately. I would like to get the same offer by many other readers with experience, willing to share it for the benefit of all this readership. Unfortunately, for the time being, he left after reading my comment that I would have preferred enriched content with more informative paragraphs. I did not want to dishearten him, I just pointed out that together we could come up with a more instructive note. I hope he will try again, and I invite all Readers to contribute their special interesting input.

14 - Bulletin Board 14.1 - 2nd Arabia Essen Welding & Cutting

14.2 - Metal + Metallurgy China 2015.

14.3 - 6th International Conference on

14.4 - Dissimilar Material Welding Joining Workshop

Watch - The Video: and also BUILT BY: Click on this Logo NOW! Copyright (©) 2015, by Elia E. Levi and

See you next time...

|

||||||||||||

| Back to Back Issues Page |