| Back to Back Issues Page | ||||||||||||

|

||||||||||||

|

PWL#138,New Hybrid Process, Improving Operations,Low Hydrogen Electrodes,Underwater Laser Cutting February 02, 2015 |

||||||||||||

| We hope you will find this Letter interesting and useful. Let us know what you think of it.

PWL#138 PWL#138 - New Hybrid Induction Assisted Arc Welding, Improving Running Welding Operations, Low-Hydrogen Covered Electrodes Filler Metal, Underwater Laser Beam Cutting for Nuclear Decommissioning, Induction Heating Assisted Underwater Wet Welding, Bridge-repair (NEW) and Resources (NEW) on Bridge-repair and much more...

February 2015 - Practical Welding Letter - Issue No.138

Important NoticeThe Mid January 2015 Issue of Practical Welding Letter, Bulletin 104, dealing with online Resources on Bridge Repair (NEW), was not distributed by e-mail but it is available at Bulletin 104 and from the updated Welding Resources Page.

DON'T USE REPLY to send your messages! Use the Contact Us form instead.

You are urged to pass-along this publication to your friends, if you like it, and if you think they may enjoy it. The addresses reported hereafter were live and correct at the time of their publication. Note: References to articles or other documents are given here in one of two forms. If they

are URL's (Uniform Resource Locator), which is the analogue of an address, they begin with "http://..." or "www.". If the information is important to you as we hope, you may save the selected pages in a suitable folder on your Computer for easy reference. (Sponsored Links)

1 - Introduction 2 - Article - Hybrid Induction Arc Welding 3 - How to do it well: Improving Running Welding Operations 4 - Low-Hydrogen Covered Electrodes Filler Metal 5 - Online Press: recent Welding related Articles 6 - Terms and Definitions Reminder 7 - Article: Underwater Laser Cutting for Nuclear Decommissioning 8 - Site Updating: Bridge-repair (NEW) and Resources (NEW) on Bridge-repair 9 - Short Items 10 - Explorations: beyond the Welder 11 - Contributions: Induction Heating Assisted Underwater Wet Welding 12 - Testimonials 13 - Correspondence: a few Comments 14 - Bulletin Board

2 - Article - Hybrid Induction Arc Welding

Advancements in welding are frequently produced by synergic combinations of different processes. This latest innovation, of which we got notice from the current issue of Advanced Materials and Processes, an ASM International publication, is described there at page 34. From the acknowledgment notice one learns that it was a cooperative endeavor of several US National Agencies together with a few welding equipment manufacturers. The new process is called Hybrid Induction Arc Welding (HIAW) or High Deposition Arc Welding (HiDep). It is affirmed that the hybrid approach helps to reduce or even eliminate weld distortion and greatly increases productivity.

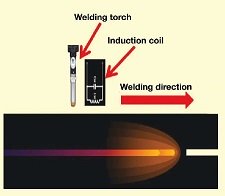

A movable induction coil that operates directly before the welding (GMAW) torch preheats the joint edges at or near the melting temperature. The welding arc heat melts the filler metal. The major benefits claimed are twice to four times faster speed, relative to conventional arc welding, and substantially reduced weld distortion. Furthermore simple square butt joints are possible, even for thick parts, remarkably simplifying joint preparation. Relative to other hybrid systems, above all the most popular that employs laser beam and GMAW, induction heating is claimed to be the best auxiliary heating method, for lower initial equipment and operating and maintenance costs. Water cooling of the induction coil allows heat generation up to 95% efficient, with power levels of 35 to 140 kW, much higher than welding arc heat. The process was used to weld steel plates up to 19 mm (0.75") thick. In higher strength and fracture toughness structural steels, the strength, ductility, and fracture toughness of the weld and heat-affected zone (HAZ) exceeded typical code and standards requirements. It is claimed that welding distortion is minimized due to induction heating being much more uniformly distributed. It is also claimed that by using an independently controllable heat source, significant flexibility is achieved in the amount and distribution of heat to the weld. Numerical modeling of the new process was carried out and verified with test data. Induction Heating Equipment was available from existing systems, while further development for adaptive fill, seam tracking and coil height stand-off control is ongoing. The purpose is to integrate new systems with robotic or mechanized welding operations. Additional development will address welding of thicker steel plates and adapting the process to other materials. Hybrid induction-plasma cutting is also in development. Interested readers are urged to seek the quoted article for complete information and references. Without recommending nor endorsing this innovation, as a service to our interested readers, we would like to address them to the developer, to get additional information:

From the quoted article of AM&P, January 2015, page 35

3 - How to do it well: improving running welding operations

It is common knowledge in the industry that most of the running welding lines, especially the oldest ones, are not optimized. Therefore they present a wide margin of potential improvement, if the problem is dealt with properly, and if some effort is invested in clarifying the issues. First one should establish the actual costs by recording all expenses. A simple spread sheet listing all the items should be drawn, and someone should be in charge of keeping it updated. Waste and losses to be reduced are found by checking the entries in the above spread sheet against the minimum needed for each of the voices in order to perform the production assignment. In parallel one should keep track of the time actually needed to execute all the elementary operations, to find out why delays happen and what should be done to reduce them. It is quite probable that the costliest losses come from lost working hours, due to failure to provide smooth production sequences. Examining all recorded occurrences will provide a pattern, suggesting causes and remedies to unsatisfactory results. Failure to produce the required quality at the first attempt may become another costly issue, to be reduced by finding the reasons for defective work and the means to achieve the goals. Just following a given operation in detail and recording its daily performance may produce a better response from the workers, if these are associated to the struggle for improvement as a necessary condition for continuing success.

4 - Low-Hydrogen Covered Electrodes Filler Metal

A useful reminder of the reasons for selecting this type of electrodes and of the rules on how to store them before use, is the content of an article published by the January 2015 issue of the Welding Journal at page 28. When the economics of the job at hand favor the use of manual Shielded Metal Arc Welding (SMAW), which uses covered electrodes as filler metal, one should just check if special requirements should be placed on the hydrogen content of the covering. There may be a code requirement not subject to individual judgement. But if the base metal is a steel of improved mechanical properties, it tends to have 0.4% or higher Carbon Equivalent (see Alloy Steel Welding). These steels have increased susceptibility to Hydrogen cracking. Therefore it is quite important to select low hydrogen covered electrodes if welding is performed by the SMAW method. See also Hydrogen Embrittlement. Low hydrogen electrodes come with different requirements relative to the maximum acceptable level of diffusible hydrogen like H16, H8, H4 or H2 (where the number indicates the maximum value in measured milliliters of hydrogen per 100 g of weld deposit [mL/100g] ). However it is not sufficient to specify the correct low hydrogen electrodes: once delivered in moisture proof packages, the responsibility to keep them dry rests with the welding shop. It is imperative to use heated rod ovens to store them before usage. The quoted article reminds that AWS E7018 electrode is the most popular low-hydrogen covered electrode type presently in use, an ideal choice for all position welding, with the exception of downhill welds. They offer smooth, quiet arc characteristics with low spatter and easy slag removal, making it the electrode preferred by welders of all skill levels. Several welding codes prescribe the use of specific low-hydrogen electrodes for critical welds. Readers whose responsibility requires the selection of low-hydrogen electrodes for SMAW, may profit by seeking the original article quoted above.

5 - Online Press: recent Welding related Articles Technology Strategy Board Study Explores NDT testing Virtual welder saves metal, money at CCC Welding course filling an industry need Robots Fill the Welding Gap Guidance for mechanised GMAW of onshore pipelines

Workers exposure to electromagnetic fields from welding processes

6 - Terms and Definitions Reminder Plasma Arc Spraying Torch is a device where an electric nontransferred arc is maintained between a tungsten electrode and a constricting nozzle, heating a pressurized inert gas to plasma state. Powder parts injected in the plasma jet are heated and propelled at high speed against a substrate, creating a dense surfacing material layer. Quality Costs should be identified as additional time, materials and operations necessary to perform the job, and included in cost estimates. Robotic Arc Welding Systems use gas metal arc welding or flux cored arc welding processes for performing roboting welding using an automatically controlled reprogrammable multipurpose manipulator programmable in three axes or more. Stationary Shoe is a backing shoe that remains in a fixed position during welding. Thermal Spray Deposit Tensile Strength is determined by separating in a tensile testing machine a thermal sprayed specimen adhesive bonded to an unsprayed specimen. The minimum strength of the adhesive must be verified to correspond to specification. Ultrasonic Examination Calibration Test Blocks are used to perform calibration of equipment to verify the detection of the smallest unacceptable defect equivalent. Visual Standards images or sample weldments, submitted by the fabricator and accepted by the purchaser can be used as guides to acceptable appearance. Weld Pass Sequence is the order in which weld passes are deposited.

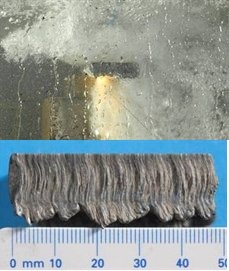

7 - Article: Underwater Laser Cutting for Nuclear Decommissioning How many welding maintenance contractors are actively engaged in maintenance and decommissioning of nuclear equipment? Probably not many. But the information relative to what is needed to do the job is open to all interested professionals who could possibly learn new techniques available to perform special tasks. Maintenance and Decommissioning of nuclear reactors are serious endeavors, to be performed at the right time in order to avoid dangerous outcomes. Previous systems based on Abrasive Water Jet Cutting generated disposal problems of large amounts of contaminated waste. Accepting a contract by the UK's Nuclear Decommissioning Authority, TWI developed prototype equipment for cutting of metal pipework and concrete scabbling in environmental acceptable ways. Laser cutting in air required complex personal protection gear (see the following TWI video:) A special underwater process, using a remotely operated high power fibre laser with a concentric air jet to blow away molten material drops, was developed to reduce the environmental impact. It proved useful both for tube cutting and for removing the contaminated surface of concrete with a device for collecting debris. For a summary of the program see: Gas-assisted underwater laser cutting of pressure tube stubs of pressurized heavy water reactor (PHWR)

Photo from

Underwater Laser Cutting The photographs show the cutting in progress and the resulting cut edge. .xtend- life.com/img/d/b003.gif" border="0"> 8 - Site Updating: Bridge-repair (NEW) and Resources (NEW) Both Pages of this Month deal with welding repair of metallic construction bridges, than need continuing monitoring and maintenance to remain safe. The first page on Bridge-repair introduces the routine examinations of the majority of existing metallic bridges done to find premonitory signs of danger requiring urgent repair to avoid catastrophies. It reviews also continuous automatic monitoring systems designed to deliver signs of distress as soon as the sensors detect suitable signals from the construction they are built to protect. The second page, Bulletin 104, provides links to online Resources on Bridge Maintenance and Repair, likely to display pertinent information to all interested people in search of such references. It is hoped that both pages might be useful to all in need to know. As usual readers already know, large amounts of information are freely available to anyone in the Welding Advisers website. One can review the Site Map and the Index Welding Page to find what one looks for. One can also perform a search, by typing the requested terms in the box that appears in almost every page of the Welding Advisers website: the Results Page(s) will include also the pertinent articles of all issues of this Practical Welding Letter. Questions, comments and feedback are always welcomed.

9 - Short Items

10 - Explorations: beyond the Welder Will Falling Oil Prices Kill Wind and Solar Power? China Says Its Gender Imbalance "Most Serious" in the World Lost Mars Lander Found in NASA Photos Popular Cable-Stay Bridges Rise Across U.S. to Replace Crumbling

Spans Deep-Fried Graphene Spheres Could Make Good Battery Materials

11 - Contributions: Induction Heating Assisted Underwater Wet Welding

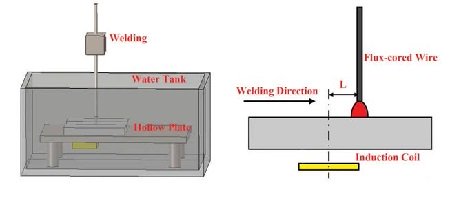

Induction Heating is described in section 2 above as an essential component of an innovative combined process recently introduced. It is amazing to find it again in a different application where it provides substantial advantages as described further on. Tinkering with combining different processes seems to be one of the preferred ways used by innovators to come up with interesting suggestions. Of course it will take time and further toil to sort out the real advantages of the combined process and to assess its economic potential. But it should be interesting to follow present research in order to get a feeling of active trends, even if it may still be far the day when they mature to actual applications. The investigation that took our attention was published at page 8-s of the Welding Research Supplement of the Welding Journal, January 2015 issue. The abstract informs that the addition of induction heating to regular underwater wet welding could reduce the cooling rate of the joint. Moreover the mechanical properties of the joint were improved through addition of induction heating. Fracture morphology changed as well, showing characteristic uniform dimples belonging to ductile fracture. The article opens with a review of current applications in offshore oil drilling structures, affirming that the demand for underwater welding processes that can produce quality wet welds at greater depths, and on a variety of materials, will continue to increase. The authors explain the main problems facing innovators. The high carbon equivalent, greater than 0.4%, of High Strength Low Alloy (HSLA) Steels used for offshore structures, and the considerable amounts of diffusible hydrogen, which combine to cause brittle weld microstructure and porosity, due to the high cooling rate in the aqueous environment. As the usual means to improve the outcome rely on Post Weld Heat Treatment (PWHT) which is difficult to apply in water submerged structures, and does not provide reliable results, the authors investigated how Induction Heating could reduce the cooling rates of the joint in underwater wet welding, by extending the t8/5 (the cooling time range from 800° to 500°C). The experimental setup placed an induction coil parallel to the weld bead. Several welds were performed after changing parameters to obtain different temperature profiles. The distance between the axis passing at coil mid length and the flux cored wire torch position was established at 20 mm as that giving the most stable arc. The study included detailed examination of the relevant microstructures obtained under various conditions, tensile tests and fracture morphology. Also impact testing and bend testing were employed, and a special y-slit restraint test helped determine cracking susceptibility. The results support the conclusion that induction heating could reduce the cooling rate of the welded joint in water and improve microstructural and mechanical properties. Readers are urged to read the original article on

From the above paper, page 9s

12 - Testimonials On Wed Jan 07 08:35:34 2015, the following results were submitted from the "Form 5" on welding-advisers.com: Name: Dani Cass

E-Mail Address: removed for security

Country: United Kingdom Dani

On Wed Jan 21 06:06:02 2015, the following results were submitted from the "Form 5" on welding-advisers.com: Name: Laxman Gurav

E-Mail Address: removed for security

Country: India

13 - Correspondence: a few Comments I understand that readers are busy with their own worries and have little time and patience for activities perceived as nuisance. It is a pity, because with a little attention, readers with experience could contribute interesting pieces to enrich this publication. They could also express their opinion on this letter, and could steer the arguments treated toward those more interesting to a larger public. Without direct exchange of ideas it is difficult to imagine which opinion readers have of my efforts. If a few kind readers could take the time to express their comments on what they read, that would provide me the best encouragement to try even harder.

14 - Bulletin Board 14.1 - 2015 North American Iron Workers/IMPACT Labor-Management Conference 14.2 - Association of Welding Manufacturers WEMCO 2015 Annual Meeting 14.3 - 9th Shipbuilding Conference 14.4 - 2015 International Brazing & Soldering Conference (IBSC 2015)

Watch - The Video: and

also BUILT BY: Click on this Logo NOW! Copyright (©) 2015, by Elia E. Levi and

See you next time...

|

||||||||||||

| Back to Back Issues Page |