| Back to Back Issues Page | |||||||||||

|

|||||||||||

|

PWL#140, Welding Superferritic, Furnaces Heating Rates, Silver-Free Brazing, New Materials, Ass. Int April 01, 2015 |

|||||||||||

| We hope you will find this Letter interesting and useful. Let us know what you think of it.

PWL#140 PWL#140 - Welding Superferritic Stainless Steel Precautions, Measuring Heating Rates in Vacuum Furnaces, New Silver-Free Brazing Filler Metals, New Materials Breakthrough for Future Demanding Applications, Asset Integrity Management, Welding-Automation (NEW) and its Resources (NEW), and much more...

April 2015 - Practical Welding Letter - Issue No.140

Important NoticeThe Mid March 2015 Issue of Practical Welding Letter, Bulletin 106, dealing with online Resources on Welding Automation (NEW), was not distributed by e-mail but it is available at Bulletin 106 and from the updated Welding Resources Page.

DON'T USE REPLY to send your messages! Use the Contact Us form instead.

You are urged to pass-along this publication to your friends, if you like it, and if you think they may enjoy it. The addresses reported hereafter were live and correct at the time of their publication. Note: References to articles or other documents are given here in one of two forms. If they are URL's (Uniform Resource Locator), which is the analogue of an address, they begin with "http://..." or "www.". If the information is important to you as we hope, you may save the selected pages in a suitable folder on your Computer for easy reference.

(Sponsored Links)

1 - Introduction 2 - Article - Precautions when welding Superferritic 3 - How to do it well: Measuring Heating Rates in Vacuum Furnaces 4 - New Silver-Free Brazing Filler Metals 5 - Online Press: recent Welding related Articles 6 - Terms and Definitions Reminder 7 - Article: New Materials for Future Demanding Applications 8 - Site Updating: Welding-Automation (NEW) and its Resources (NEW) 9 - Short Items 10 - Explorations: beyond the Welder 11 - Contributions: Asset Integrity Management 12 - Testimonials 13 - Correspondence: a few Comments 14 - Bulletin Board

2 - Article - Precautions when welding Superferritic.

An introduction to welding Superferritic Stainless Steels was published (2) in Issue 115 of Practical Welding Letter for March 2013. Here we report on a note by Damian J. Kotecki in his Q&A section published in the March 2015 issue of the Welding Journal at page 20. Asked for pitfalls of welding such steels, the world renowned expert of anything stainless, cautions against contamination of shielding gas (argon or helium) with nitrogen or hydrogen entrained from surrounding air if turbulent (instead of laminar) flow occurs over the weld area. Hydrogen must be avoided also in the form of moisture from surrounding air. Also excessive heat input or exposure to high temperature may promote the precipitation of dangerous phases or intermetallic compounds that can embrittle the weld or the heat affected zone. Repair welding is risky and must be avoided or at least qualified by examining the resulting ductility that may be impaired. The recommended solution is adopting mechanized or fully automatic Gas Tungsten Arc Welding. Some grain growth in the weld and in heat affected zones (HAZ) is unavoidable, but a little can be tolerated. Grain growth is a cause for the loss of toughness (shift to higher ductile-to-brittle fracture transition temperature) in the HAZ. Undoing grain growth once it occurred is practically impossible in normal production situations involving welded heat exchangers of these superferritic stainless steels. The author concludes: "So it is essential to weld correctly the first time to avoid any need for repair".

3 - How to do it well: Measuring Heating Rates in Vacuum Furnaces

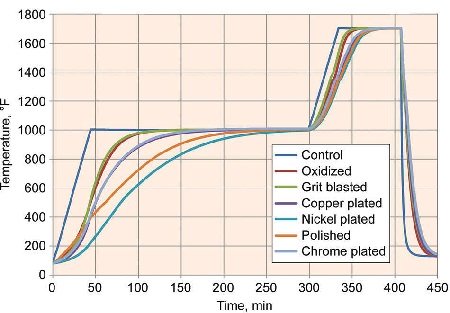

The accepted practice used to measure temperature in vacuum furnaces is to place suitable thermocouples into small holes drilled into dummy blocks. Except that researchers of a major furnace manufacturer found an unexpected surprise when trying to develop a vacuum carburizing cycle for a workload of a certain part. This indicated that the parts were not held at the correct temperature long enough before carburizing. The investigators reached the conclusion that surface emissivity is an important factor to consider. Therefore they set up an experiment to test the heating rates in various blocks with different surface conditions and finish. The testing program performed is summarized in an article published in the HTPro supplement of the ASM Heat Treating Society, included in the March 2015 issue of Advanced Materials and Processes (AM&P), a publication of ASM International, at page 40. The following conclusions are derived from this study and reported here from the publication above:

Interested readers are urged to seek the original publication.

on time to heat carbon-steel test blocks in a vacuum furnace. [From AM&P, March 2015, page 41]

4 - New Silver- Free Brazing Filler Metals

Once again our preferred source for innovations in Brazing is the insert Brazing and Soldering Today, published periodically in the Welding Journal. In the March 2015 issue at page 40 one can find the article on the evaluation of the new materials highlighted in the title to this note. The drive to look for alternatives to the excellent silver based brazing filler alloys is the high cost of silver. Those proposed till recently were unable to match the properties of the original alloys they were intended to substitute. A commercial company took the initiative to formulate and test new brazing alloys intended to be less costly due to the absence of silver. But the article recognizes that "there are still no silver-free brazing filler metals in the industry that provide low brazing temperatures and have sufficient ductility and strength of brazed joints". The difficulties with new alloys include the relative propensity to develop brittle intermetallic compounds and precipitates like carbides nitrides or phosphides. The article describes the brazing performed in air by heating with a propane torch low carbon steel both bare and nickel plated and 304 stainless steel, using the two proposed new silver free alloys. For comparison also two silver containing and another known silver free alloy were employed. Testing conducted on the samples included metallographic examination and spreading area evaluation. Shear strength and ductility were determined by tensile testing of brazed specimens. The conclusion of the study permits to assert that one of the proposed new commercial alloys provides sufficient strength and ductility to show performance comparable to the best silver based alloy. Unfortunately its melting range is much higher than that of the material it should have substituted. Interested readers are urged to seek the original article indicated above.

5 - Online Press: recent Welding related Articles Download TWI Connect Issue 8 - January/February 2015 from Transition to Welding Robotics Inevitable Across Industries Globally Coldwater joins Edison Welding Institute The Global Welding Products Market and the End-Users That Drive It Kongsberg delivers welding cameras for RPRS Applied Welding Engineering - Processes, Codes, and Standards (Book)

6 - Terms and Definitions Reminder Inspection Activities include formal review, verification and assessment of specific documentation, means and practices to be used before, during and after welding completion. Linear Elastic Fracture Mechanics (LEFM) first assumes that the material is isotropic and linear elastic. Based on the assumption, the stress field near the crack tip is calculated using the theory of elasticity. When the stresses near the crack tip exceed the material fracture toughness, the crack will grow. LEFM is a highly simplified, yet sophisticated, theory that deals with sharp cracks in elastic bodies. Mechanical Structure Sensitive Properties include Ultimate Strength, Yield Strength, Fatigue Strength, Hardness, Ductility, Elastic Limit, Damping capacity, Creep Strength, Rupture Strength and Toughness. Notched Specimens are used in various types of impact testing for evaluating materials under different testing temperatures. Oxygen Cylinder is the container used to store and transport pure compressed oxygen for industrial use. Projection Weld Size is the diameter of the weld metal in the plane of the faying surfaces. Resistance Welding denotes a group of welding processes that produce coalescence of the faying surfaces with the heat obtained from resistance of the workpieces to the flow of the welding current in a circuit that includes the workpieces, while mechanical pressure is applied. Single Bevel Groove is a joint formed between the beveled edge of one element and a planar surface of the other butting member.

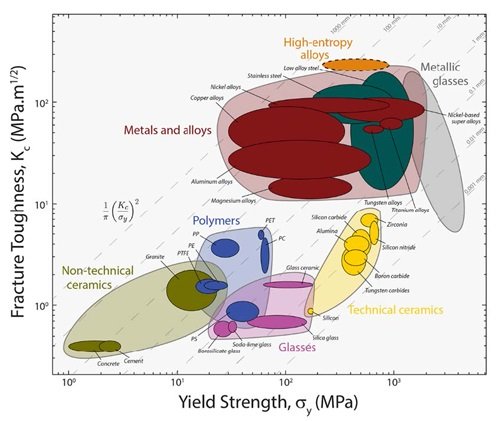

7 - Article: New Materials for Future Demanding Applications

More than a decade already passed from the first trials concerning a new class of complex metallic materials potentially capable of exceptional mechanical properties. Several research centers around the world are busy with exploring different aspects of this new field, developing these materials and testing their properties. They are different from conventional alloys in that they are built of five or more principal elements, all of them in large proportions of about the same molar concentration (equimolar ratio). This is a major change in alloy design from traditional physical metallurgy, and it opens up a new path for explorations of new materials and new properties. These are called High-entropy alloys (HEAs), standing at the new research frontier. The name comes from the fact that they appear as random solid solutions of many elements, much more stable than traditional alloys because of their large entropies of mixing, which are responsible for their lowered tendency to ordering and segregation. During solidification these alloys tend to form nanostructures of ultrafine crystallites, that greatly improve their strength and hardness. Some of the alloys behave as if their phases were undergoing a solution hardening mechanism. Other alloys show remarkable resistance to anneal softening. Some of these alloys, with good stability, high temperature strength and acceptable ductility are promising candidates for high temperature applications in that they provide also corrosion and oxidation resistance. But their most striking feature is possibly the potential for the development of countless new alloys, just by exploring the combinations of mutually miscible metallic principal elements, ready for further modification of processing and properties. The sheer number of those possible combinations is the main reason for the long development time that must be dedicated to experimental research before announcing any set of researched alloys ready for tentative applications. Traditional metallurgists may feel overwhelmed by this new information. It will take time until they absorb the fundamental knowledge in the field, summarized in the following book. A thorough presentation can be found in the Description, available from the reported link hereafter. High-Entropy Alloys A short page on the subject is downloadable from:

8 - Site Updating: Welding-Automation and its Resources The Pages of this Month deal with a hot subject: how can a shop upgrade productivity without taking excessive risks. Whenever a production line is fed continuously by a substantial order backlog, even if the batches are somewhat different, it is probably the right time to explore in detail what could be done to enhance production, how much the project would cost and what benefits could be gained. The problems have been mastered by equipment providers. Experience shows that with duly preparation and with personnel thoroughly instructed to deal with routine maintenance, the transition can be smooth and the targets of improved productivity can be reached, The new website page is available by clicking on the link Welding-Automation. The page of Resources on Welding Automation is available from the link Bulletin 106. Some useful information might be obtained from both pages for all curious people wishing to know more on the subject. As usual readers already know, large amounts of knowledge are freely available to anyone in the Welding Advisers website. One can review the Site Map and the Index Welding Page to find what one looks for. One can also perform a search, by typing the requested terms in the box that appears in almost every page of the Welding Advisers website: the Results Page(s) will include also the pertinent articles of all issues of this Practical Welding Letter. Questions, comments and feedback are always welcomed. Don't use Reply, use the Contact Us form instead.

9 - Short Items

9.1 - Galvanic Series is a list of metals and alloys arranged according to their relative corrosion potentials in a given environment. 9.2 - Hot Pressure Welding is a solid-state welding process that produces coalescence of materials with heat and application of pressure sufficient to produce macrodeformation of the base material. 9.3 - Impact Test is used for determining the energy absorbed in fracturing a test piece at high velocity, as distinct from static test. The test may be carried out in tension, bending, or torsion, and the test bar may be notched or unnotched. 9.4 - Ledeburite is the eutectic of the iron-carbon system, the constituents of which are austenite and cementite. The austenite decomposes into ferrite and cementite on cooling below Ar1, the temperature at which transformation of austenite to ferrite or ferrite plus cementite is completed during cooling. 9.5 - Milling Cutter is a rotary cutting tool provided with one or more cutting elements, called teeth, that intermittently engage the workpiece and remove material by relative movement of the workpiece and cutter. 9.6 - Nucleation is the initiation during recrystallization, of a phase transformation or of the growth of a new phase, and possessing an interface with the parent metallic matrix of a phase at discrete sites, with the new phase growing on the nuclei.

10 - Explorations: beyond the Welder Battle Over Science Funding Gets Fiercer In U.S. Congress Explained: The Supertide that Swallowed a French Abbey Total Solar Eclipse Wows Northern Tip of Globe Why Some of Google's Coolest Projects Flop Badly Hopped-Up Particle Accelerator Poised to Venture into the Realm of Exotic Physics

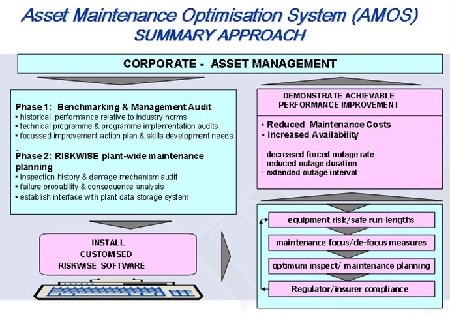

11 - Contributions: Asset Integrity Management Within an industrial organization involving the operation of complex plants, Assets Integrity Management is the function charged with demonstrating that, as far as it is reasonably practicable, the integrity of the assets is properly taken care of. Typical of the kind of environments bound to enact an effective policy, capable of achieving operational excellence and maximum asset performance with acceptable results at minimum cost, are oil and gas production, transportation and refining facilities, power generation plants, and chemical factories using dangerous materials. A well managed program helps operators identify deficiencies, care for health, safety and the environment and reduce safety risks before they escalate. Furthermore, by focusing on asset integrity, it can also play a major role in extending the life of aging assets. The purposes are obviously to avoid major disasters, likely to injury human lives and to compromise the returns on important financial investments, but it has slowly been accepted that this policy is also essential to the success of the business. It is important that the single individuals charged with the responsibility to promote actions and to take decisions affecting asset integrity be fully aware of their responsibility and be totally committed to their task. But the success of a company’s ability to operate safely and efficiently depends heavily on the cooperative spirit and on the mutual confidence that the management is able to instill in the organization and in all its members. Many commercial enterprises offer specialized investigations and other consulting services on the current fitness to service of individual components or of complete installations during the whole lifecycle of the asset. Recommended further reading on this subject:

[From the above TWI Document, Fig.1]

12 - Testimonials

On Sun Mar 08 01:03:04 2015, the following results were submitted from the Name: Sathish Kumar

On Thu Mar 19 07:40:19 2015, the following results were submitted from the Name: Ingvar Sveinsvoll

13 - Correspondence: a few Comments It should not come as a surprise to my readers that, implementing my new policy, I am now asking the payment of a modest price, USD 10.75, for any answer they may wish to get from me. It was not an easy decision from my part, but it came to me most naturally as I realized, after years of answering to the most strange and not-sufficiently-thought-through questions I got. For one thing, I can see a useless query from a distance, when essential details are missing in the formulation of the question, often vague and ill defined. It appears as if the inquirer signals me he/she is not really interested in the problem and any reaction would be accepted. What disturbed me most was the fact that most of the recipients, even as I dedicated quite some time to research and write down my answer, accepted it as due from me, without even thinking of thanking me for my effort. I would have expected, quite naively I admit, that they should be grateful for some real help, and care to provide some follow up on how their problem was finally resolved. It should not be understood that I am ready to study and provide useful answers for any project that might be thrown my way, for the meager price mentioned above. Far from that. A good project will cost quite a sum, proportional to the effort and time required, and to the benefits to be gained. I can see sometimes big problems that the inquirers have no idea how they should be tackled for saving substantial waste of efforts and resources. But they refrain from the idea of asking professional help, for some ill conceived conviction that they know better. I would be delighted to be asked to provide substantial benefits for solving some of the most nagging hindrances occurring in real production. But someone should be first convinced that it may pay to look after solutions.

14 - Bulletin Board 14.1 - AWS Weldmex 14.2 - International Thermal Spray Conference and Exposition 14.3 - Cladding Conference 14.4 - Shape Memory and Superelastic Technologies Conference and Exposition

Watch - The Video: and also BUILT BY: Click on this Logo NOW! Copyright (©) 2015, by Elia E. Levi and

See you next time...

|

|||||||||||

| Back to Back Issues Page |