| Back to Back Issues Page | |||||||||||||||

|

|||||||||||||||

|

PWL#141,Welding Engineering Career, Dry Gas to Brazing Furnace, Low Hydrogen Filler Metal, New Exten May 01, 2015 |

|||||||||||||||

| We hope you will find this Letter interesting and useful. Let us know what you think of it.

PWL#141

PWL#141 - Welding Engineering as a Career, How to get dry Gas at the Brazing Furnace, Benefits of Low Hydrogen Filler Metal Electrodes, Modern Non Contact Extensometers, Learning through Games, High Entropy Alloys (NEW) and Resources (NEW) and much more...

May 2015 - Practical Welding Letter - Issue No.141

Important NoticeThe Mid April 2015 Issue of Practical Welding Letter, Bulletin 107, dealing with online Resources on High Entropy Alloys (NEW) was not distributed by e-mail but it is available at Bulletin 107 and from the updated Welding Resources Page.

DON'T USE REPLY to send your messages! Use the Contact Us form instead.

You are urged to pass-along this publication to your friends, if you like it, and if you think they may enjoy it. The addresses reported hereafter were live and correct at the time of their publication. Note: References to articles or other documents are given here in one of two forms. If they are URL's (Uniform Resource Locator), which is the

analogue of an address, they begin with "http://..." or "www.". If the information is important to you as we hope, you may save the selected pages in a suitable folder on your Computer for easy reference. (Sponsored Links)

1 - Introduction 2 - Article - Welding Engineering as a Career 3 - How to do it well: How to get dry Gas at the Brazing Furnace 4 - Benefits of Low Hydrogen Filler Metal Electrodes 5 - Online Press: recent Welding related Articles 6 - Terms and Definitions Reminder 7 - Article: Modern Non Contact Extensometers 8 - Site Updating: High Entropy Alloys (NEW) and Resources (NEW) 9 - Short Items 10 - Explorations: beyond the Welder 11 - Contributions: Learning through Games 12 - Testimonials 13 - Correspondence: a few Comments (HELP!) 14 - Bulletin Board

2 - Article - Welding Engineering as a Career

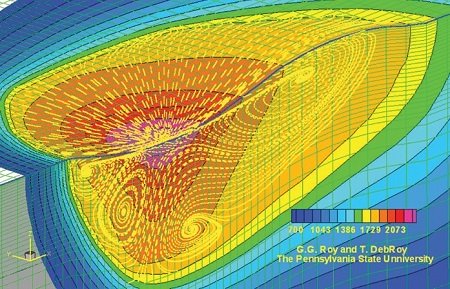

"Is becoming a welding engineer a good career choice today?". This is the question that opens an article published in the April 2015 issue of the Welding Journal at page 58. It was written by Professor Tarasankar Debroy, Materials Science and Engineering, Penn State University, University Park, Pa., who is known for published papers on his research work. The article makes a point in stressing the importance of welding in many present and future realizations of projects, vital to the well being of society at large. No question about that. The arguments presented explain why deep understanding of fundamental processes is necessary to clarify otherwise mysterious results occurring in daily welding practice. Problem solving is helped by the analytical capability recently available through advancements in computer hardware and software, that made fluid flow and heat transfer calculations accurate and affordable. The article explains in some detail the latest developments and new understanding achieved in the study of flow in the welding pool as a function of certain important factors. This same subject was treated in a past issue of Practical Welding Letter, but new progress was achieved meanwhile. In PWL#045, an article was published on Welding Effects of S Content on Stainless Steels kindly contributed (11) by Ph.D. Timothy E. Volin. The author conveys the excitement of discovery upon understanding basic phenomena in welding. It is certainly very true not only in welding but in every field of scientific investigation. There is still much more to study and clarify in many aspects of welding operations. And pursuing a research career in welding metallurgy is a worthy endeavor likely to provide challenges and satisfactions to whoever likes and finds pleasure in this exacting pursuit. This very specific occupation is however not necessarily the job of the average welding engineer. While a strong scientific base is necessary to the person embracing this career to perform satisfactorily in any productive industry, the basic research illustrated in the enlightening article is possibly quite remote from the engagements of an engineer in his/her daily struggle. Besides metallurgical problems, daily productivity requirements and quality goals are perhaps more pressing exigencies, depending on the structure of the job and on the nature of interpersonal relations. One of the most important appeals of welding engineering is probably the versatility, or the breadth of different specific tasks that may be required from a dedicated individual. That gives chances to find in the organization congenial jobs, rewarding in terms of challenge, interest and satisfaction, waiting to be filled and providing inviting ways to advancement. To get a fair idea of what kind of preparation needs the individual wishing to become a Welding Engineer, look at the source. Find the Description of requirements for obtaining AWS Welding Engineer Certification. Then browse through the various titles and review in depth the Body of Knowledge (4 pages). Interested readers may find personal points of view of people who chose welding as their career for life. Short interviews were published in several Practical Welding Letter. Look for issue 42 and all the issues from 73 to 79 from the Index of Past Issues of PWL. To encourage the selection of this profession as a career for life, academic institutions and industries in need of future professional employees should show, to young people looking for advice, the varied facets and the many opportunities of careers in welding engineering.

Computed flow of weld metal during arc welding. The colors represent temperatures

in K and the dotted lines represent the lines of flow of liquid. The two loops shown

near the surface are from the Marangoni flow and the two loops below the surface result

from electromagnetic force (Ref. 4).

3 - How to do it well: How to get dry Gas at the Brazing Furnace

Answering a question from a worried reader, Dan Kay, an expert brazing consultant contributing to the Q&A column in the Welding Journal (April 2015, page 30), agrees that "for most brazing operations the dew point must be -60°F/-50°C or colder to achieve good brazes." He then lists the precautions that should be in place to make sure that the gas from the tank will not absorb moisture along the pipeline to the furnace. These are his recommendations: 1. Use only certified gas piping, beware of standard copper and steel tubing, See also:

4 - Benefits of Low Hydrogen Filler Metal Electrodes

An Article published at page 66 in the April 2015 issue of the Welding Journal reminds the well known danger of letting hydrogen enter welds and produce cracks, especially in high strength steels, and provides the viewpoint of manufacturers on the benefits of using proper consumables. This is imperative for certain industries like pipelines, offshore structures and heavy equipment where high strength materials are increasingly used, and for service where temperature extremes may be normal. The use of low hydrogen filler metals is just one more precaution to be taken when confronted with demanding applications. Knowledge of the common designators per AWS Standards helps in the selection. Along the years, several articles were published in this Practical Welding Letter on topics related to this concern. Those can be found in #08, #88, #96, and #115, reachable from the Index of Past Issues of PWL. The article above reminds that Hydrogen-induced cracking typically occurs at temperatures below 600°F (316°C) (commonly around 300°F/140°C or below) and appears within a day or two of completing the weld. Shielded metal arc welding electrodes with 18 classification are a good choice for low-hydrogen applications that require portability. These include AWS E7018, E8018, and E9018 SMAW electrodes, which all meet the H4 designation, indicating less than 4 mL of diffusible hydrogen per 100 g of weldment. Some low-hydrogen SMAW electrodes may feature R designators, defined in AWS A5.1-91 (for example, AWS E7018 H4R), which indicate the product meets additional moisture-resistant requirements, making it even less prone to picking up hydrogen, which could result in cracking. To obtain this designation, the SMAW electrode must have successfully undergone testing that proves it is moisture resistant (within a specified range) after being exposed to 80°F (26.7°C) temperature and 80% relative humidity for 9 h. These products, in addition to offering low hydrogen levels, are usually user-friendly, having a forgiving arc and low spatter levels, and providing good penetration. Solid wires and metal cored wires of correct hydrogen content suffix designation are usually preferred options when hydrogen induced cracking is a possibility. Flux cored wires can be made to satisfy low hydrogen requirements, although their manufacture is possibly more difficult. According to the author, formulations have improved remarkably over the years, and presently many smooth-operating flux cored wires are available. Furthermore electrodes for different steel strength ranges are available depending on requirements, with options from 70 ksi (AWS E71T-1MJ H4) up to 128 ksi (AWS E111T1-K3MJ H4) for crack sensitive quenched and tempered steels or for offshore structural fabrications that will be subject to temperature extremes. Storage of this type of consumables should be given adequate attention, especially after the original hermetic package has been opened. Interested Readers are urged to seek the original article mentioned above.

Using filler metals with low-hydrogen designations helps minimize one source of hydrogen in the welding process. In today's marketplace, there are several options available for welding high-strength steels, each with their own characteristics that can also benefit the welding process. [From the above Article, the Welding Journal, April 2015, page 68]

5 - Online Press: recent Welding related Articles The Basics of Weld and Process Monitoring Laser welding facilitates order from e-mobility industry What’s the Difference Between Resistance-Welded Fasteners and Arc-Welded Studs? (Downloadable pdf) Hydraulic Solution for Flash-Butt Welding Clamp it down Optical Clarity: Why It's Important and What It Means for You

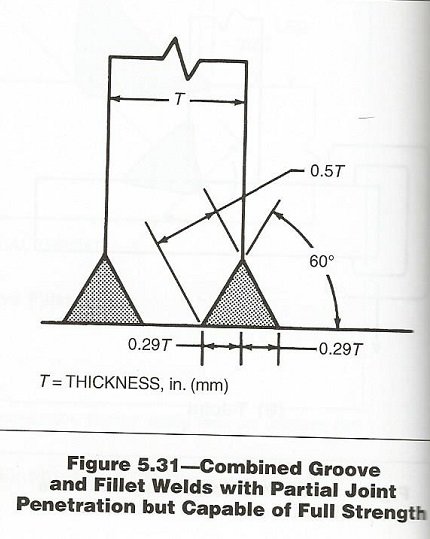

6 - Terms and Definitions Reminder Acid Core Solder is a solder wire or bar containing an acid flux in the core. Backup, in flash and upset welding, is a locator used to transmit the upset force to the workpieces and to prevent them from slipping during upsetting. Cap is a non standard term used to indicate the last final layer of a groove weld. Delayed Crack is a non standard term used instead of cold crack or underbead crack. Edge Shape means the shape of the edge of the joint member. Flux Cover is a layer of molten flux protecting the bath of molten filler metal in dip brazing or soldering. Groove-Fillet Weld Combination is a composite joint including both groove and fillet welds and capable of full strength even with partial penetration.

[Fig. 5.31 from page 194 of AWS Welding Handbook Ninth Edition Volume 1]

Hardfacing is a surfacing process variation in which suitable surfacing material is deposited to reduce wear.

7 - Article: Modern Non Contact Extensometers

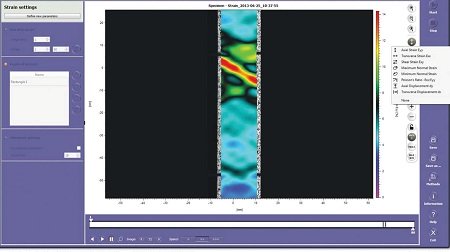

An introduction to extensometers, the instruments which measure the strain of stressed physical bodies, was published (7) in Issue 36 of Practical Welding Letter for August 2006. Click on PWL#036 to see it. Now an article, written by a technically competent employee of a commercial supplier, published in the April 2015 issue of AM&P (a publication of ASM International) at page 22, extols the benefits of using non contact extensometry when testing mechanical properties of delicate materials. For these applications, non contact optical instruments, have obvious advantages. But flexibility of use is also remarked as a special advantage in controlled environments. Then the selection of any one from various interchangeable lenses as best adapted to the situation is considered a bonus, and ease of use for automatically operating instruments requiring minimum human intervention. High temperature applications as in test furnaces, where mechanical contact with the specimen may be problematic, are much simpler and more reliable for non contact extensometers. Finally the robustness of the instruments, without moving parts, is remarked as a guarantee for long and consistent use without maintenance problems, and a recommendation for selection. It is reported that recently video extensometers have been employed to collect images for digital image correlation (DIC). Patterns engraved on specimen surfaces are sequentially recorded while the specimen is being stressed. The images are then analyzed to build a strain map that describes the strain condition on the whole surface examined. Such a map permits to locate singularities like discontinuous yielding, shear strain, localized necking and hot spots. The technique that was used for special research has now be simplified and integrated in commercially available modern extensometers, bringing this powerful analytical tool also to industrial laboratories. Interested readers are urged to seek the original article, gaining the opportunity to contact the author, if deemed necessary for clarification or demonstration of capabilities.

Digital image correlation analysis (strain map) shows localized strain on a metal tensile specimen.

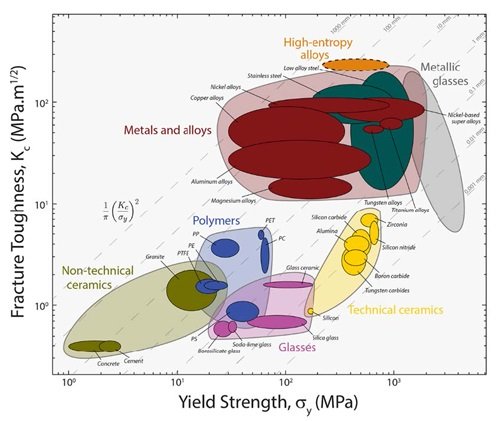

8 - Site Updating: High Entropy Alloys and Resources The Pages of this Month deal in depth and some more detail with the subject of High Entropy Alloys briefly introduced (7) in Issue 140 of Practical Welding Letter for April 2015. The new page on High Entropy Alloys describes the concepts at the root of this new metallurgical research field, far from what was known up to then, and shows that some remarkable properties were achieved. The initial successes forecast even more useful development in the future. But the road until new materials are conceived, made, tested and put to use is still long and uncertain. Much work and patience are still required. As a companion page, the new Mid April 2015 - PWL#140B - Bulletin_107, providing Online Links to useful Resources on High Entropy Alloys, was published in our website and is now available by clicking on Bulletin 107. Readers should appreciate the opportunity to learn on new materials in the making, and keep updated on this most interesting subject. Stay tuned for important new applications. As regular readers already know, large amounts of knowledge are freely available to anyone in the Welding Advisers website. One can review the Site Map and the Index Welding Page to find what one looks for. One can also perform a search, by typing the requested terms in the box that appears in almost every page of the Welding Advisers website: the Results Page(s) will include also the pertinent articles of all issues of this Practical Welding Letter. Questions, comments and feedback are always welcomed. Don't use Reply, use the Contact Us form instead.

High-entropy

alloys (orange) show an exceptional combination of toughness and strength relative to other materials. Image: Ritchie

9 - Short Items

9.1 - Surface Damage, in tribology, is damage to a solid surface resulting from mechanical contact with another substance, surface, or surfaces moving relatively to it and involving the displacement or removal of material. In certain contexts, wear is a form of surface damage in which material is progressively removed. In another context, surface damage involves a deterioration of function of a solid surface even though there is no material loss from that surface. Surface damage may therefore precede wear. 9.2 - Triple-Action Press is a mechanical or hydraulic press having three slides with three motions properly synchronized for triple-action drawing, redrawing, and forming. Usually, two slides, the blankholder slide and the plunger, are located above and a lower slide is located within the bed of the press. 9.3 - Uniform Corrosion is a type of corrosion attack (deterioration) uniformly distributed over a metal surface and proceeding over it at approximately the same rate. 9.4 - Vacuum Sintering of ceramics or metals is performed at subatmospheric pressure and elevated temperature. 9.5 - Wire Rod is a classification of Hot-rolled coiled stock that is to be cold drawn into wire. 9.6 - X-Ray Spectrum is the plot of the intensity or number of x-ray photons versus energy (or wavelength).

10 - Explorations: beyond the Welder China's Great Green Wall Helps Pull CO2 Out of Atmosphere Adaptive Headlights Could Help Drivers Avoid Hitting Bambi Hubble’s Repairman Reflects on the Telescope’s Legacy Dark Matter May Feel a "Dark Force" That the Rest of the Universe Does Not Robotic Surgery Opens Up

11 - Contributions: Learning through Games The article published in the April 2015 issue of the Welding Journal at page 48 is probably controversial. While the author maintains that games can create learning opportunities to be used for specific work training, he goes a long way to convince readers that young students (the gaming generation) were born into a technological revolution requesting early adaptation to the use of modern communication means. That is why they are completely at ease with all new gadgets. That gives them a jump start in exploiting available media, showing them useful information in an easily assimilable format. That means that traditional teachers must make an effort to agree that new ways like on screen games can and should be used to promote transmission of knowledge and of special skills. Serious games are those designed for a purpose different from pure entertainment. It is reported that industries like military, health care, emergency management, and engineering dedicate much thought to the production of games designed to impart specific capabilities. A new word, Gamification, is used to convey the concept of using game thinking to engage in problem solving. The article reports conclusions from the Education Arcade at Massachusetts Institute of Technology, that game players regularly exhibit persistence, risk taking, attention to detail and problem solving. Engagement makes the difference, as students see the advantage of using technology to make learning more meaningful. This may mean that the most practical games could be designed by recent students who got the message and who know how to apply successfully the technology to the benefit of other fellow students. Also the subject of Virtual Reality is mentioned, which was recently criticized in these pages by a skeptic reader. (See (11) in PWL#139). Using games to engage, teach and train future workforce is still

a challenge. Readers are urged to seek the original article mentioned above. Those with first hand experience are invited to share their insight here by writing their thoughts in the Contact Us form. See also:

[From http://top5onlinecolleges.org/gamification/]

12 - Testimonials Name: Raed Alanbari

Name: Isam Dkwr regards,

13 - Correspondence: a few Comments (HELP!) Note: - To be able to improve our service, we ask unsubscribing readers to comment on their decision. Here is what a kind unsubscribing reader had to tell us. I answered his call. I expressed my sympathy and compassion but I cannot really help him. 08 Apr 2015 Dear Elia

Levi, I will be as blunt as possible, as you have requested. I have no passion for welding. My passion was psychology. From the age of 12, which was 20 years ago, I was deciding between that, and computers, because I loved both equally as far as their effect on me. By 14, I had resolved the issue, because I realized (in my admittedly theoretical estimation) wise counseling would ripple through multiple generations. I probably didn't mention that I was never educated. Well, I was never educated. That is why I wanted to learn psychology. My deepest passion was to learn to teach other parents, like my own, how to raise children for the best. I took the ACT. I got a 32, which put me in the top 1% of the nation, or better. My dad and mom immediately took credit, in their tiny box-church. They didn't mention the many years I had no education whatsoever, or that the fact I had left the house once in one year meant leaving it twice was "too much." But I realized my suspicions were correct. I was not stupid. I was smart. If the people running it really were both smart and honest. *laughs* So my college years happened. I was offered multiple full- scholarships around the US. I picked the nearest one to me, because I didn't know how to function in society. I didn't know how people got, haircuts, for example. It turns out being raised in boxes doesn't lend itself to knowledge. Hell, anything more complicated than scheduling a haircut probably would have blown my mind. All I knew was, I wanted to know the right way to raise kids. My earliest memories were toddlering up to a mountain of flesh (Mr. Mustang of Arkansas) and informing him that "....It's...It's not nice to make mommy cry." And, after facing a showdown of death in the eyes, being slammed against our cheap trailer wall and choked until blacking out. I was never afraid of another man after that incident, btw. I figured you can survive anything if you survive a showdown with a man who weighs 15x what you do, and has murder in his eyes, and you're 3. It served me well when I was homeless in the fifth most violent city in the nation. I kept on with my passion, though, surviving off of potatoes bought with selling my blood plasma, sleeping in the university's underground drainage system. I wanted to know how to raise kids. I felt the world needed to know! I never really found out how. I was just an undergrad student, and our fucking PROFESSORS were all divorced, all clueless with what to do in their own personal lives, all at odds with their kids and step kids. Fucking worthless. I wasn't looking to teach a bunch of people for a $100,000+ plus benefits, plus strutting around like I was "SOMETHING" when I was.. failing the exact same god-damned thing I was trying to escape. Fuck them. I went to automotive school. That was complicated. I found I loved cars and mechanical systems. It was the first time I had ever loved anything other than psychology. The school I went to was pretty much a welfare scam, and didn't teach you how to do anything. I was okay with that. I just read books, multiple curriculums, and watched youtube videos. I ended up scoring #34 in the nation, for all mechanic school students. This was despite my teach[er] trying to prevent me from working on cars at all, because "it made the shop dirty." I asked him who his boss was (I forget what his title was) and marched into his office. I told him every single student for the past two years had simply flipped through several hundred pages of procedures and initialed, as directed, and it was very, very easy to prove, upon the slightest inspection. The next day, the professor told me I could do whatever I wanted. Ok! good. Well, you sit up here and take a nap. Accomplishing this, I was left with two options. GM was in a major shutdown phase.

But, when asked to address classrooms, I told them: there's always room for the best. But, my little brother invited me down to Jackson, MS. I desperately wanted to be with family. Which, I loved helping customers, and had many, many compliments to management for going above and beyond the call of duty. Other managers hammered me for everything they could find: dirtying my uniform, spending too much time on the telephone with a single customer (when there was no other thing to be doing!) etc. I went insane. I had to be institutionalized. And, despite working super full-time at autozone for 3 months, with super reviews, they denied my healthcare, and I was stuck with tens of thousands of dollars of debt. There was nobody I hated more than my parents. But, I told them my situation, and, I have to hand it to them in all their mis-management: they invited me in. I analyzed my options.. I needed to make money, and I didn't have much time.. I enrolled in welding school. In months, I was making more money than I have ever made in my life. And the job is so simple, my brain will explode if I don't find something (secretly) to listen to while doing my job. Sadly... none of the wonderful things you throw your brain at affect me. Keep your productivity low! Keep your quality low! I was shocked but, it made sense. No wonder american manufacturing is shutting down left and right! Honest workers, talented workers, are hated. I started drinking, heavily. I do my job, then I come home, and sit down, and turn on the tv. What more is there? But I respect you. You have such a serious amount of knowledge, and passion! and you gladly share it for free! It burns my chest, actually. I wanted to be that. I wanted to be that, for psychology, and child rearing. So, that is why I quit. Because I can't handle your passion anymore. I see no purpose. -jg.

14 - Bulletin Board 14.1 - ITSC 2015 - International Thermal Spray Conference and Exposition

14.2 - AWS 2nd Welding Education, Skills, and Certification Conference 14.3 - AWS HighTemperature - Metals Conference 14.4 - AWS 18th Annual Aluminum Conference. Sept. 22–24. Omni Hotel - San Diego, Calif. http://www.aws.org/events/detail/18th-annual-aluminum-conference

Watch - The Video: and also BUILT BY: Click on this Logo NOW! Copyright (©) 2015, by Elia E. Levi and

See you next time...

|

|||||||||||||||

| Back to Back Issues Page |