| Back to Back Issues Page | |||||||||||||||

|

|||||||||||||||

|

PWL#143,Advice to Welding Engineer,Acoustic Imaging for process QC, Rotating Arc Welding Technology July 01, 2015 |

|||||||||||||||

| We hope you will find this Letter interesting and useful. Let us know what you think of it.

PWL#143 PWL#143 - Wise Advice to the New Welding Engineer, Acoustic Imaging for process quality control, A New, Rotating Arc Welding Technology, Metallurgical call up, HTPro - June 2015, Using Magnetic Barkhausen Noise to analyze Case Depth, the use of the Residual Gas Analyzer to evaluate the performance of heat sources, Welding-materials, Resources on Welding Inspection and much more...

July 2015 - Practical Welding Letter - Issue No.143

Important NoticeThe Mid June 2015 Issue of Practical Welding Letter, Bulletin 109, dealing with online Resources on Welding Inspection (NEW) was not distributed by e-mail but it is available at Bulletin 109 and from the updated Welding Resources Page.

DON'T USE REPLY to send your messages! Use the Contact Us form instead. This publication brings to the readers practical answers to welding problems in an informal setting designed to be helpful and informative. You are urged to pass-along this publication to your friends, if you like it, and if you think they may enjoy it. The addresses reported hereafter were live and correct at the time of their publication. Note: References to articles or other documents are given here in one of two forms. If they are URL's (Uniform Resource Locator), which is the analogue of an address, they begin with "http://..." or "www.". If the information is important to you as we hope, you may save the selected pages in a suitable folder on your Computer for easy reference.

1 - Introduction 2 - Article - Wise Advice to the New Welding Engineer 3 - How to do it well: Acoustic Imaging for process quality control 4 - A New, Rotating Arc Welding Technology 5 - Online Press: recent Welding related Articles 6 - Terms and Definitions Reminder 7 - Article: Metallurgical call up 8 - Site Updating: Welding-materials (NEW), Resources on Welding Inspection (NEW) 9 - Short Items 10 - Explorations: beyond the Welder 11 - Contributions: HTPro - June 2015 12 - Testimonials 13 - Correspondence: a few Comments 14 - Bulletin Board

2 - Article - Wise Advice for the New Welding Engineer

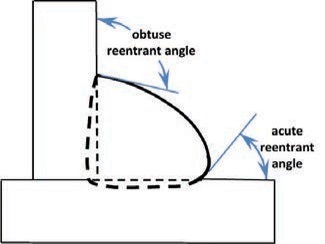

The position of Welding Engineer in any industrial organization risks not to be fully appreciated by those in charge of establishing lines of responsibility and authority. It can so happen that a conscientious welding engineer, especially if new to the profession, be required to endorse decisions contrasting his/her best judgement. That is why it is essential that welding engineers be aware of the requirements of their important task, in view of applying an enduring effort to build and enlarge the base of their own career by accumulating knowledge and experience. A helpful hand is extended by an old professional, to young people in need of wise advice, in the form of an instructive article, published in the June 2015 issue of the Welding Journal at page 66. The Author, acknowledging that some schools of welding engineering may lack to provide sufficient instruction in all the required aspects, so summarizes his thoughts: Becoming proficient requires years of experience. At the beginning of a long and rewarding career in this job, those who can profit the most should be open to accept the words of wisdom so graciously offered. It is recommended to read and study the instructive original article. Deep familiarity with the most common and useful welding standards helps in the interpretation of welding requirements for qualification, inspection and acceptance. The Author confirms the statement that "some designers...don't understand welding [...] and this often results in overly conservative designs [...], less manufacturable". Therefore he further recommends that the welding engineer perform routinely the Weld-design-review, as we emphasized elsewhere at this link. He then reviews some of the most useful standards, stressing that learning their contents provides a larger view of applicable requirements, useful also for establishing, when required, qualification tests. A practical suggestion to young welding engineers is his encouragement to pursue the recognition of AWS Certified Welding Inspector, that would provide much needed experience in deciding if certain welds meet quality requirements or not. It is important to know and recognize the classification of structures as introduced by D1.1, because that may affect different acceptance criteria. Specific examples of different weld profiles are shown, with additional considerations relative to their acceptability. The article concludes that existing standards provide the technical basis of success in their coverage of qualification, fabrication and inspection. The final advice of this important article is that when confronting other individuals attempting to apply their own "requirements" (in excess of those required by applicable Code or specification), "Your best defense is to have a better understanding of the real requirements through your knowledge and experience". Readers are urged to seek the original article pointed at above. Interested readers and young welding engineers may enjoy also another article, published in the same June 2015 WJ at page 80, reminding essential elements of Welding Procedure Specifications (WPS).

[From the Welding Journal, June 2015, page 69]

3 - How to do it well: Acoustic Imaging for process quality control

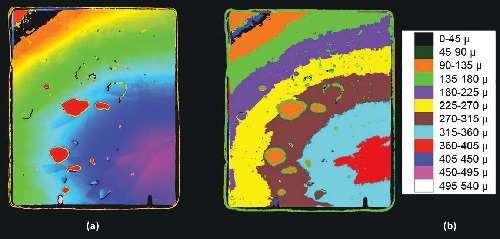

An Article published at page 18, in the June 2015 issue of Advanced Materials and Processes (AM&P), an ASM International publication, sheds new light on acoustic microscopy advancements helping to control delicate manufacturing processes and to assess the quality of individual material layer thickness in costly items playing important industrial functions. This is achieved by mapping of the point-by-point contour of interfaces and by measuring layer dimensions. Tilted or warped interfaces, as well as voids or solder irregularities, stand out in the display, as color differences readily appreciable at a glance. Two quite different examples are presented. The first, insulated gate bipolar transistor (IGBT) should be able to handle heavy electrical current loads in critical applications. Its makeup should assure that large amounts of heat produced during operation are dispersed effectively by the heat sinks. Minor irregularities in the various layers may compromise performance. The second example uses the same technology to examine internal material interfaces in a much different application, namely manufacturing polycrystalline diamond (PCD) material for use in cutting tools such as oilfield drill bits. The material is made by sintering a layer of PCD on top of a tungsten carbide layer. These sintered layers form a wafer that can be cut into individual tool bits, with the top PCD layer used to perform the actual cutting. In both examples discussed in the article, one face of the buried layer is flat and horizontal. If buried layers were distorted on both surfaces, this acoustic method can image both layer surfaces and map the thickness of the distorted layers. Scanning Acoustic Microscopy as a nondestructive examination method was briefly introduced (9.4) in this

publication, in Issue 17 for January 2005. An Article on Nondestructive Acoustic Cross Sectioning was published (7) in Issue 135 of Practical Welding Letter for November 2014. Interested readers are encouraged to seek the original article mentioned above.

[From AM&P June 2015, page 21]

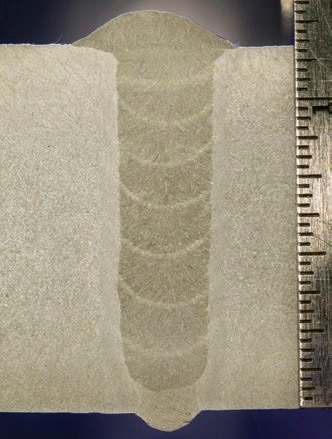

4 - A New, Rotating Arc Welding Technology

An article, published in the June 2015 Issue of the Welding Journal at page 34, introduces a new Rotating Arc Welding Technology, called SpinArc™ by Weld Revolution, Spring, Tex. The article was written by personnel of the company: while exposing the working principles and providing some information on results obtained, it does not reveal the originators of the idea, the process of developing it into a working system, the problems, if any, that had to be solved, nor if it was tested and evaluated by extraneous entities. The technology utilizes a unique welding gun and control system. It is similar to GMAW but the special torch makes the contact tip, tip holder and end of the wire spin in a conical shape. Because of this motion, centrifugal force propels the molten droplets towards the joint, creating a consistent and sound weld bead. It is affirmed that this process minimizes incomplete fusion, porosity and undercut. The article claims various productivity advantages, including higher wire feed speed and increased deposition rates, improved capability to weld successfully out of flat position and to fill narrow grooves without bevel. Besides the welding parameters, to be controlled through a standard constant voltage (CV) power source or in pulse mode (GMAW-P), three variables must be set for each weld: spin speed, diameter and direction (not specified, possibly of revolution, either clockwise or counter-clockwise). It is reported that, for surfacing with corrosion resistant alloys, it is advantageous to increase the spin diameter (up to the maximum, 8 mm). The article describes a few applications, giving the parameters used in practice. An interesting case is shown for a 0.5 in thick complete penetration groove weld, made from one side with two passes, both at 18.5 in./min (47 cm/min). Also fillet welds were produced successfully. Among the benefits mentioned by the author, increased productivity and improved quality. Certain applications will appear more fit than others to exploit successfully the advantages offered by this new technology. Until then the suppliers will have to demonstrate their practical applications in seminars and exhibitions, to win the attention of potential customers, always in search of increasing productivity and reducing costs. Interested Readers are urged to see for themselves the original article pointed at above. Those with practical experience in this new technology are invited to share here their valuations.

[From the Welding Journal, June 2015, page 36]

5 - Online Press: recent Welding related Articles Welding lighter materials Welding automation takes hold Fast silicon micromirrors improve laser cutting and welding K-TIG TAKES OUT DEFENCE INDUSTRY INNOVATOR AWARD, 2015 Explore the welding equipment market - global industry analysis and forecast 2015 - 2021 6 - Terms and Definitions Reminder Laser Hazards include eye damage, burns, electrical shock, respiratory system damage and chemical hazards. Manifold of gas cylinders is a header for interconnection of multiple gas sources with distribution points. Overhead Welding Position is that assumed by the welder when welding is performed from the underside of the joint. Protective Personal Equipment (PPE) items are devices or clothing accessories to be worn by the welder when performing work, to protect the body from being injured by the welding environment. Root surface underfill is a condition where the weld root face is below the adjacent surface of the base metal. Step soldering is a method for successive soldering of joints in a given part with solders of successively lower soldering temperature so as to accomplish the joining without disturbing the joints previously soldered. Throat Area is the area bounded by the physical parts of the secondary circuit in a resistance spot, seam or projection welding machine. Used to determine the maximum dimensions of a part that can be welded. Weld Symbol is a graphic character connected to the reference line of a welding symbol specifying the weld type. 7 - Article: Metallurgical call up

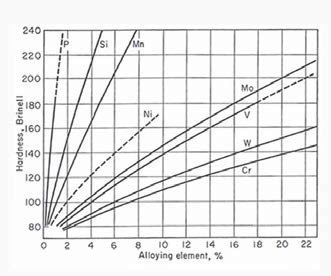

The influence of steel composition on its weldability should be well understood when planning to weld a new steel. But also more traditional materials may require some study to check if old procedures are still valid or if some changes might provide interesting improvements. New materials may offer advantages that require knowledge to exploit their properties to their full potential. An Article reminding basic metallurgical information on exactly such consequences on weldability was recently published in the June 2015 issue of the Welding Journal at page 72. It is certainly useful to rehearse from time to time basic knowledge that might be overlooked, essentially the influence of different ingredients in the makeup of steels on basic weldability or ease of welding, as given in this article. Carbon equivalent, the article reminds, provides a measure of weldability, quantifying the cumulative effects in a single calculation result, intended to give guidance in selecting proper conditions for successful welding. Furthermore it may be useful to check different formulas for Carbon Equivalent as given in the article, that may be more exact in certain cases, more accurately predicting preheating temperatures and risk of cracking. The diagrams reported in the article and the references given at its end may help to reach a deeper understanding of unexplained results compromising the outcome of welding operations and to find suitable precautions like additional thermal treatments to assure success. Interested readers are urged to seek the original article pointed at above, to assure their understanding and to learn more proficiently the teachings offered in the article. They may find also complementary information in our pages on Alloy Steel Welding and on Weldability Testing.

8 - Site Updating: Welding-materials, Resources on Welding Inspection The new Pages of this Month cover two unrelated subject. Obviously not all materials are weldable with the same ease. The overall property addressing this problem is called weldability. The new volume, In the next issue of this publication a short review of the new volume will probably be included. The first of our pages addresses some common problems regarding all weldable materials. It can be found at Welding Materials. While it reviews general concepts concerning all weldable materials, it should be supplemented by the pages dedicated to the specific ones, available in this website. The other page, published as a Mid Month Bulletin, provides links to online resources relative to Welding Inspection. It should be useful when searching specific inspection means or techniques. Large amounts of knowledge are freely available to anyone in the Welding Advisers website. One can review the Site Map and the Index Welding Page to find what one looks for. One can also perform a search, by typing the requested terms in the box that appears in almost every page of the Welding Advisers website: the Results Page(s) will include also the pertinent articles of all issues of this Practical Welding Letter. Questions, comments and feedback are always welcomed. Don't use Reply, use the Contact Us form instead.

9 - Short Items

9.1 - Electron Bands are Energy states for the free electrons in a metal, as described by the use of the band theory (zone theory) of electron structure. Also called Brillouin zones. 9.2 - Ferrite Banding are parallel bands of free ferrite aligned in the direction of working. Sometimes referred to as ferrite streaks. 9.3 - Grit Blasting is abrasive impact blasting with small irregular pieces of steel, malleable cast iron, or hard nonmetallic materials. 9.4 - Heat Tinting means coloration of a metal surface through oxidation by heating, to reveal details of the microstructure. 9.5 - Intergranular Stress-Corrosion Cracking (IGSCC) is Stress-corrosion cracking in which the cracking separation occurs along grain boundaries. 9.6 - Mandrel is a blunt-ended tool or rod used to retain the cavity in a hollow metal product during working. Or a metal bar around which other metal may be cast, bent, formed, or shaped. Or a shaft or bar for holding work to be machined.

10 - Explorations: beyond the Welder Researchers Study Three Promising Antiaging Therapies Graphene: Looking Beyond the Hype What Is the Big Secret Surrounding Stingray Surveillance? Extreme Temperatures Linked to Changing Air Patterns Gravity Kills Schrödinger's Cat

11 - Contributions: HTPro - June 2015

The new Issue 2 of Volume 3 of this HTPro, a publication of the Heat Treating Society of ASM International, is offered as an insert to the subscribers of Advanced Materials and Processes, June 2015 Issue. It is also available to the general public by performing a Search using the title above, or at: One remarks an

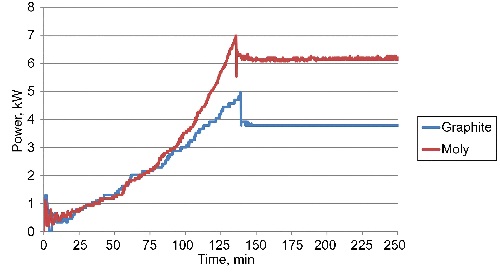

article on The Barkhausen effect was introduced in this publication in two short notes in Issue 22 of Practical Welding Letter for June 2005. Click on PWL#022 to see them. The first note is in section 6 under Terms and Definitions, the second is in section 9.2. The article reported in the above publication, referring to a specific commercial instrument for determining Case Depth, is somewhat disappointing in that the accuracy offered is lower than that of traditional destructive methods, despite its advantages as to higher speed of testing and less training requirements. The other article explains the use of a Residual Gas Analyzer in a study to assess performance of different heat sources (graphite vs. molybdenum) and the relative advantages of graphite. From the advertisement page of a furnace manufacturer on can get access to an informative page titled

Apart from the advertising tips, that readers should evaluate on their merits, one can get information on Specification requirements and on how to best equip one's furnaces to meet them.

It seems good and useful information, valuable to those having responsibility in furnace operations.

12 - Testimonials On Mon Jun 08 12:48:35 2015, the following results were submitted from the "Form 5" on welding-advisers.com: Name: Brian Collard [...] Do you know anything about this welding process?

On Wed Jun 17 12:09:37 2015, the following results were submitted from the "Form 5" on welding-advisers.com: Name: Cliff Buckner

13 - Correspondence: a few Comments From the question of a correspondent who wanted help to find an article of ours reported in a Google search, I understand that readers may not be aware of the fact that useful information can be found also in past issues of this publication, namely the Practical Welding Letter. Normally in a search, the location is also given, as a full URL (a kind of address). But if that information is incomplete, readers can consult the complete list at the Index of Past Issues of PWL. Another reader asked for business information in a certain geographic area: that is beyond the scope of our interests, and not covered in our publications.

14 - Bulletin Board 14.1 - 2nd Welding Education, Skills, and Certification Conference AWS HighTemperature Metals Conference 18th Annual Aluminum Conference MS&T 2015 - Materials Science & Technology 2015 FABTECH 2015

Watch - The Video:

and also

Watch the following

POWERED BY: Click on this Logo NOW! Copyright © 2015, by Elia E. Levi and

See you next time...

|

|||||||||||||||

| Back to Back Issues Page |