| Back to Back Issues Page | ||||||||||||

|

||||||||||||

|

PWL#144,Last HandBook Volume,Changes to ASME Sect. IX,Filler Metal Spec. Changes, Additive Mfg.iTSSe August 03, 2015 |

||||||||||||

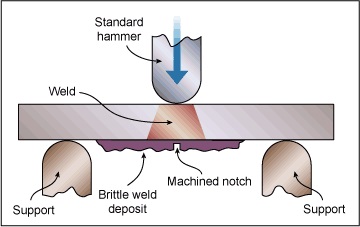

| We hope you will find this Letter interesting and useful. Let us know what you think of it.

PWL#144

PWL#144 - The last (fifth) Volume of the Ninth Ed. of AWS Welding Handbook, Changes to ASME Section IX, Filler Metal Spec. Changes, Additive Manufacturing, Welding Engineering and relevant Resources, ASM Thermal Spray Society Newsletter (iTSSe) and much more...

August 2015 - Practical Welding Letter - Issue No.144

Important NoticeThe Mid July 2015 Issue of Practical Welding Letter, Bulletin 110, dealing with online Resources on Welding Engineering (NEW) was not distributed by e-mail but it is available at Bulletin 110 and from the updated Welding Resources Page.

DON'T USE REPLY to send your messages! Use the Contact Us form instead. This publication brings to the readers practical answers to welding problems in an informal setting designed to be helpful and informative. You are urged to pass-along this publication to your friends, if you like it, and if you think they may enjoy it. The addresses reported hereafter were live and correct at the time of their publication. Note: References to articles or other documents are given here in one of two forms. If they are URL's (Uniform Resource

Locator), which is the analogue of an address, they begin with "http://..." or "www.". If the information is important to you as we hope, you may save the selected pages in a suitable folder on your Computer for easy reference.

1 - Introduction 2 - Article - The Last Volume 3 - How to do it well: Changes to ASME BPVC Section IX 4 - Filler Metal Spec Changes 5 - Online Press: recent Welding related Articles 6 - Terms and Definitions Reminder 7 - Article: Additive Manufacturing 8 - Site Updating: Welding Engineering and Resources 9 - Short Items 10 - Explorations: beyond the Welder 11 - Contributions: ASM Thermal Spray Society Newsletter 12 - Testimonials 13 - Correspondence: a few Comments 14 - Bulletin Board

2 - Article - The Last Volume

I hold in my hands, with pleasure and confidence, the Volume 5 of the AWS Welding Handbook 9th Edition, just delivered: WHB-5.9 WELDING HANDBOOK VOLUME 5 - MATERIALS AND APPLICATIONS PART 2 This volume covers non ferrous metals and non metallic materials including ceramics, plastics and composites. In its ten Chapters all the main nonferrous materials are presented, with practical hints on how the different processes should be used to obtain successful weldments. Readers who need a broad introduction to specific aspects of welding, will peruse this volume as a learning source, rich with the condensed experience of several contributors. Those who need an encyclopedic source, where the most important subject affecting the welding of these materials are exposed with clarity, will enjoy the ease with which one can find the important factors affecting results. It is practically impossible to summarize usefully the abundance of examples, illustrations and practical suggestions for applying successfully welding or other joining processes. Readers with the most different interests will find easily what they need. In the aluminum alloys section, different alloys are introduced with their components and properties, with indication of useful heat treatments where applicable. Filler metals and their selection rules are explained, to achieve the properties sought. Arc welding processes and their main parameters are introduced to help in establishing practical welding procedures. Modern processes including linear friction and friction stir welding are briefly mentioned and illustrated, while a thorough section is dedicated to properties and performance. In the magnesium metal section the various alloys are introduced, with their components and their influence on mechanical and corrosion resistance properties. Available and recommended consumables are introduced and their use is highlighted. An interesting Refill Friction Stir Spot Welding is illustrated: the spot weld is made without leaving an indentation or a mark on the surface when completed. Copper and nickel are treated in two rich chapters, covering also transition elements used for joining incompatible dissimilar materials that cannot be fusion welded together. Lead and Zinc, Titanium and its alloys, Reactive, Refractory and Precious metals are dealt with in three thorough chapters, and then the subject changes to Plastics, Ceramics and Composites, which may be new subjects to those of us who work generally with metals. AWS should be praised for their cooperative effort which concludes the publication of the Ninth Edition of the Welding Handbook. These five volumes should be in the bookshelf of every professional, for learning and consultation.

3 - How to do it well: Summary of Changes to ASME Section IX, 2015 Edition

Those who work with ASME Boiler and Pressure Vessel Code should be advised of a new 2015 Edition of the Section IX. An article with the above title, written by Walter J. Sperko, was published in the Welding Journal for July 2015 at page 74. The changes become mandatory on Jan. 1, 2016. Code users can readily see revisions and corrections at The article is made of several sections dealing with the following subjects. Administrative Changes Welding Procedure (QW200) Changes Welder Qualification (QW300) Changes Base Metals and Filler Metals Brazing (QB) Changes Plastic Fusing – Part QF Simultaneous Qualification of Welding Personnel under Both ISO and ASME Standards The presentation in the article is thorough and complete although the author advises that the opinions expressed there are not necessarily those of ASME. Not daring to attempt to summarize the article, for the risk of inducing readers in error, we will limit this note to report on the new edition and on the introductory article pointed at above. Readers are urged to seek the original article pointed at above. 4 - Updating of Metal Filler Specifications

In the article reported above in section 3, the section on Base Metals and Filler Metals at page 76 of the Welding Journal for July 2015 shows an updated list of consumables specifications in the ASME 2015 Edition of Section IX. The list includes recently updated ASME SFA or AWS welding filler metal specifications. Also several new alloys are mentioned, which were assigned P numbers, with comments where applicable. And several new aluminum alloy filler metals are indicated, which were added to the F-number table. Those who are bound to ASME Code should care to make due diligence work to assure meeting the new requirements as soon as necessary. 5 - Online Press: recent Welding related Articles Extending weld life Namibia: Simulator Teaches Advanced Welding Chinese rebar: BAR's new technical guidance note AUTO FOCUS: As automation evolves, collaboration between labor and machine becomes paramount Download for metal heads: AHSS Guidelines (276 pages) 6 - Terms and Definitions Reminder Magnetic Arc Blow is a magnetic disturbance causing the arc to point away from the point of welding due to change of direction of the current flow as it enters the work, and to asymmetric arrangement of magnetic materials around the arc. Nil-ductility transition (NDT) temperature of ferritic steels is the temperature at which the fracture mode of steel changes from ductile to brittle. It is determined by the ASTM E208 drop weight test. Oxygen Lance is a length of pipe used to convey oxygen to the point of cutting in oxygen lance cutting. Pulse start delay time is the interval from current initiation to the beginning of current pulsation. Quench hardening in ferrous alloys, is produced by austenitizing and then cooling at a rate such that a substantial amount of austenite transforms to martensite. Recycled Slag is fused submerged arc welding slag, recovered and processed for reuse. Seal bonding material, in thermal spraying, partially forms, in the as-sprayed condition, a metallic bond with the substrate. Taper delay time is the interval, after upslope, during which the maximum welding current or high pulse current is constant.

[From Compact tension and J integral tests

7 - Article: Additive Manufacturing We last made reference to this subject in PWL#106 of June 2012. It may be the right time now to come up with updates. It is common knowledge that 3D printing has gained enormous popularity as a technology for building physical objects

from a drawing and a software program without the use of tooling. The advantages sought in the new approach to manufacturing of bodies with intricate geometries are essentially reducing component lead time, cost, material waste, energy usage, and carbon footprint. For aerospace applications the economic use of material has significant importance because, to make useful parts with traditional subtractive processes, the largest part of a block is removed and wasted by machining. In medical applications, individually adapted details are essential for personal suitability. In the maintenance of older machinery or installations, rapid production of single spare parts is often a necessity, to keep operational availability. It is probably important, to the curious professional, to get a balanced view of the progress gained in the past several years, and at least an idea of the development of sophisticated technologies to produce parts to be used for most demanding applications. A short historical review may help in building a mental image of the various attempts that were done to translate the idea into working systems. A detailed description of the various approaches of the different technologies with their specific requirements becomes clear with examples of realized parts. The following article is recommended as an overview of the recent progress in Additive Manufacturing. Development and Implementation of Metals Additive Manufacturing (14 pages)

It was designed by Shapeways shop owner Bathsheba Grossman.

From: Hot Trends in Additive Manufacturing 8 - Site Updating: Welding-Engineering and relevant Resources This Month our Pages have an ambitious program. We would like to encourage people working in the welding industry not to think that their present position is the peak of their Career. On the contrary, it is an advantageous starting point for higher and higher achievements. There are many way to progress. Just study what is available and decide that you will do whatever it takes to improve your knowledge and your experience. It may not be easy, it will take time and efforts but it is feasible and extremely rewarding. The first Page on Welding Engineering shows how you should take the initiative to put your good qualities to fruition. A lot of information is available at no cost in this website and elsewhere. Profit by learning and gaining experience to build your own career. The second page, Bulletin 110, called also the Mid July Bulletin 2015 or PWL#143B, is essentially a Resource Page, or a list of online sources from where the curious readers may be able to draw useful information. Large amounts of knowledge are freely available to anyone in the Welding Advisers website. One can review the Site Map and the Index Welding Page to find what one looks for. One can also perform a search, by typing the requested terms in the box that appears in almost every page of the Welding Advisers website: the Results Page(s) will include also the pertinent articles of all issues of this Practical Welding Letter. Questions, comments and feedback are always welcomed. Don't use Reply, use the Contact Us form instead. 9 - Short Items

9.1 - Mineral dressing is physical and chemical concentration of raw ore into a product from which a metal can be recovered at a profit. 9.2 - Nuclear grade is Material of a quality adequate for use in nuclear application. 9.3 - Overbending means bending metal through a greater arc than that required in the finished part, to compensate for springback. 9.4 - Pyrometallurgy is High-temperature winning or refining of metals.

9.5 - Quench-age Embrittlement of low-carbon steels results from precipitation of solute carbon at existing dislocations, and from precipitation hardening of the steel caused by differences in the solid solubility of carbon in ferrite at different temperatures. 9.6 - Roughing Stand is the first of several stands of rolls through which a reheated billet passes in front of the finishing stands.

10 - Explorations: beyond the Welder What You Don't Understand about Suicide Attacks

Kepler 452 b: What It Would Be Like to Live on Earth's "Cousin"

Hillary Clinton Vows to Make U.S. a Clean Energy Superpower

Future Flying Car Solves Parallel Parking Problem

Decoding the Remarkable Algorithms of Ants

11 - Contributions: ASM Thermal Spray Society Newsletter

The July-August 2015 issue 3 (vol. 10) of the International Thermal Spray and Surface Engineering(iTSSe) was inserted in the July-August 2015 issue of Advanced Materials and Processes (AM&P) a publication of ASM International. It is also available for download (18 pages) from: http://www.asminternational.org/documents/10192/25622267/amp17307p35.pdf The main article discusses which options Plasma-Sprayed Heat Shields offer to Thermal Management, especially to reflect heat away from the transmission’s regulator and control cockpit temperatures of racing cars but also for other machinery where excess heating of sensitive components might affect performance. Besides the traditional methods of applying insulators, a UK company is offering products that feature ceramic platelets applied via plasma spray onto a metal substrate to create a heat shield that provides additional temperature resistance. One can specify one or more layers, all very thin, suitable for diverse applications, including those for restoration and maintenance of classic cars. A sandwich structure of ceramic and stainless steel, provides ceramic coating protection together with the strength and ability to form structures. The blend of materials enables these panels to protect components from both conductive and reflective heat. These capabilities are essential for downsized engines with tighter packaging, where heat management becomes a pressing concern.

12 - Testimonials Mon Jul 06 08:25:02 2015 Name: Thomas Stewart

I am really enjoying your site - found it over the weekend and will make this part of my library of knowledge. Thank you very much.

13 - Correspondence: a few Comments - A call for articles. A few readers kindly agreed, once prompted, to declare their readiness to contribute a note highlighting their experience in some aspects of welding technology, inspection matters or problems with materials. Others, who work for organizations dealing with education, offered to explain which learning aids are available to the public. PWL opens its pages to collaborators who are ready to write on anything they feel instructive and interesting to a wide public. Of course some editing may be needed, but in principle, provided some quality is present, many contributions will be accepted. We were compelled to reject only a few writings that did not stand up to basic criteria. But promising is easy. 14 - Bulletin Board 14.1 - Workshop on Weld Residual Stress and Distortion Prediction

14.2 - HighTemperature Steels Conference

14.3 - Pipeline Conference

14.4 - 18th Annual Aluminum Conference

14.5 - U.S. and European Welding Standards: Conference

of GSI/AWS

Watch - The Video:

and also

Watch the following

POWERED BY: Click on this Logo NOW! Copyright © 2015, by Elia E. Levi and

See you next time...

|

||||||||||||

| Back to Back Issues Page |