| Back to Back Issues Page | ||||||||||||||

|

||||||||||||||

|

PWL#145, Optimizing Robotic Welding, GMAW Troubleshooting, Research on Nb/SS Brazing, Ni-Co welding September 01, 2015 |

||||||||||||||

| We hope you will find this Letter interesting and useful. Let us know what you think of it.

PWL#145 PWL#145 - Optimizing Robotic Welding with the Right GMAW Gun, GMAW Gun Troubleshooting, Filler Metal for superconducting radiofrequency cavities, welding of Nickel and Cobalt alloys, Nuclear grade amendment, Contract Welding and Resources and much more...

September 2015 - Practical Welding Letter - Issue No.145

Important Notice The Mid August 2015 Issue of Practical Welding Letter, Bulletin 111, dealing with online Resources on Contract Welding (NEW) was not distributed by e-mail but it is available at Bulletin 111 and from the updated Welding Resources Page.

DON'T USE REPLY to send your messages! Use the Contact Us form instead. This publication brings to the readers practical answers to welding problems in an informal setting designed to be helpful and informative. You are urged

to pass-along this publication to your friends, if you like it, and if you think they may enjoy it. The addresses reported hereafter were live and correct at the time of their publication. Note: References to articles or other documents are given here in one of two forms. If they are URL's (Uniform Resource Locator), which is the analogue of an address, they begin with "http://..." or "www.". If the information is important to you as we hope, you may save the selected pages in a suitable folder on your Computer for easy reference.

1 - Introduction 2 - Article - Optimizing Robotic Welding with the Right GMAW Gun 3 - How to do it well: GMAW Gun Troubleshooting 4 - Filler Metal for superconducting radiofrequency cavities. 5 - Online Press: recent Welding related Articles 6 - Terms and Definitions Reminder 7 - Article: The welding of Nickel and Cobalt alloys 8 - Site Updating: Contract Welding and Resources on the same subject 9 - Short Items 10 - Explorations: beyond the Welder 11 - Contributions: Nuclear grade amendment 12 - Testimonials 13 - Correspondence: a few Comments 14 - Bulletin Board

2 - Article - Optimizing Robotic Welding with the Right GMAW Gun

The article published recently in the August issue of the Welding Journal at page 36 stresses the fact that part of the success of the robotic operation depends on the correct selection of the proper GMAW welding torch. The parameters to be checked are type and thickness of the material to be welded, weld length and amperage required. Driven by the necessity to increase productivity and to improve quality, welding automation is constantly expanding as more and more industries move into new robotics applications. Cables running through-arm in robots are becoming more prevalent in the industry because they reduce cable wear from routine torsion. In most applications, air-cooled GMAW guns provide the necessary cooling capacity to protect against premature failure. Water-cooled robotic GMAW Torches are chosen for to their ability to weld on thicker materials for longer times without overheating, especially if duty-cycles approach 100%. Then the neck of the torch should be selected to suit production requirements like accessibility. But also the length of the cables should be optimized for the application. A Nozzle cleaning station may be a useful addition. It may not be easy, though. Therefore articles like the one pointed at above should be studied thoroughly and acted upon. Readers are urged to seek it. Those with first hand experience are invited to share their observations.

In most applications, air-cooled GMAW guns provide the necessary cooling capacity [From the Welding Journal, August 2015, page 38] 3 - How to do it well: GMAW Gun Troubleshooting

We would like to address all those working with the Gas Metal Arc Welding process (also known as Mig) who may occasionally need troubleshooting because of malfunctions at the torch, to a useful article published in the August 2015 issue of the Welding Journal at page 44. The article deals with a dozen symptoms and helps in finding the culprit for each of them. From erratic arc (as judged by the sound) and porosity, to improper contact tip to work distance, from microarcing inside the conductor tube to wire drag and shavings, the welder should be alert to suitable working conditions and be ready to look for the root causes to improve quality and productivity of work. From the article one learns that many causes could generate what is commonly referred to as erratic arc, so that deep understanding of the torch working is essential for keeping it in its best working conditions and for finding how to repair faulty operations. Turbulent shielding gas flow can cause bad welds. It is therefore important to understand which conditions promote turbulence vs. laminar flow. A few checks may be sufficient to control the situation and to improve it if necessary. Interested readers are urged to seek the original article pointed to above and to review its recommendations. The author may be reachable for further explanations if necessary, or for covering subjects not dealt with in sufficient depth.

Test new components on a dedicated cylinder, and measure gas flow rates at the gun

[From the Welding Journal, August 2015, page 48]

4 - Filler Metal for superconducting radiofrequency cavities.

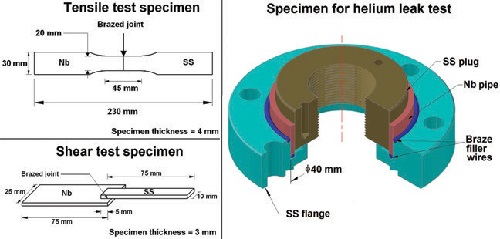

An article published in the research supplement to the Welding Journal of August 2015 at page 241-s reports on research conducted to improve brazed joints of special components needed in modern particle accelerator systems. The research was required because previous brazed joints using copper included brittle Niobium/Fe intermetallic compounds that translated in brittle rupture in delicate systems, making them unserviceable. The challenge of the research was to test new procedures for brazing vacuum tight transition elements of Niobium/316L stainless steel free of brittle intermetallic compounds. The selected brazing filler metal was BVAg8 (72Ag-28Cu eutectic; TM = 1053 K) per AWS specification A5.8. The poor wettability of the Niobium surface was adequately compensated by the excellent wettability of the Ni-plated stainless steel 316 L, that contributed to adequate capillarity. The vacuum brazing of the composite dissimilar joints was performed successfully on the nickel plated stainless steel specimens, while the joint was kept under compression at brazing temperature. The brazement was found leak proof by helium leak test and demonstrated its capability to withstand a ten hours degassing heat treatment at 873 deg. K as required by the application. No brittle intermetallic compounds were found in the brazed joints and the tensile strength was adequate, as needed. The tensile tested specimens failed by ductile fracture. The conclusion of the research confirmed that the tested lower temperature brazing procedure successfully meets all requirements for building transition joints of Niobium/316L stainless steel for the application sought. Interested readers can download the complete research paper from:

Details of vacuum-brazed niobium-316L stainless steel specimens used for the study.

[From the Welding Journal, August 2015, Supplement, page 242-s]

5 - Online Press: recent Welding related Articles Laser 2015: Audi speeds aluminum welding with remote laser Industry Demands Spark Welding Technology Changes Coating Brings MEMS Flexibility to Laser Welding TWI and Cambridge University create world welding first Improving coiled-tubing serviceability in sour environments through metallurgical design

6 - Terms and Definitions Reminder Laser Metal Deposition Welding is a surface treatment process that adds a layer or layers of material onto a workpiece for repairing or for adding wear-resistant surfaces. Metallurgy of welding is the science studying the structural modifications occurring in welded metals as a consequence of the thermal cycles applied to workpieces when making welds. Nickel and Cobalt Alloys, welding of, is the subject of Chapter 4 of the new volume 5 of the Welding Handbook, introduced in Section7 hereafter. Oxygen Arc Cutting is a process that uses an arc between the workpiece and a consumable tubular electrode, through which oxygen is directed to the workpiece. Performance Qualification is a testing procedure aiming to verify the ability of operators or equipment to produce sound applications. It applies to welding, brazing or to plasma spray operators per applicable standards. Robotic Spot Welding is performed and controlled by robotic equipment, especially in mass production of cars and vehicles. Spiking, in electron beam welding and in laser beam welding, is a faulty condition where the joint penetration is not uniform, and changes abruptly over the length of the joint. Thermal spraying operator conducts operations of automatic, mechanized or robotic thermal spray equipment and need qualification of performance before being authorized to work.

7 - Article: The welding of Nickel and Cobalt alloys

Nickel and Cobalt alloys have exceptional mechanical properties and good corrosion resistance both at elevated and at sub-zero temperatures. Therefore these are the materials of choice for demanding applications despite their high costs. The new Volume 5 of the ninth edition of the AWS Welding Handbook dedicates its Chapter 4 to these materials.

This Section as available for purchase for a nominal cost as a separate unit, Chapter 4 WHC5.04 NICKEL AND COBALT ALLOYS

from the American Welding Society, at Those who weld these materials would do well to procure at least this section (if not the whole Volume 5) for the wealth of information and practical answers offered in a practical and useful format. After a short Introduction explaining the characteristic of welding these alloys and their difference from stainless steels, some general observations are presented. Then a section is dedicated to physical and mechanical properties but starts with the crystallographic structure of the metals and on their solubility limits of other elements. The influence of small amounts of alloying elements is outlined including the adverse influence of residual elements. The main alloy groups are described with their characteristics, an detailed compositions are listed in Tables. The main characteristics of the main groups are described and their weldability is assessed. A few pages are dedicated to preparation for welding. The main welding processes are reviewed as applied to these alloys, and limitations are highlighted where applicable. New tables indicate which processes are adequate for which alloys, and notes are added on the influence of welding on corrosion resistance. Single processes are dealt with in detail, suggested joint designs are proposed and welding techniques and procedures are discussed, with indication of the causes for the faulty conditions observed. After SMAW, GTAW and SMAW are discussed in detail, specifying recommended conditions. Additional sections cover fabrication and design for high temperature service. Weld cladding by various processes is discussed in depth as this technique is widely applied in many fabrications. Alternatively the use of nickel alloy clad steel (i.e. by explosion welding) requires special techniques, fully explained, for welding the joints. Brazing, soldering, thermal and laser cutting are briefly mentioned, as are some applications of weld repair for some industries. The last section covers safe practices. The 77 pages of Chapter 4 cannot be condensed in a short note. It should be appreciated that the whole chapter covers the main subjects and that it is meant as a reference for orientation and basic learning. Readers whose practice covers the above materials are invited to explore if putting this knowledge at their fingertips is likely to improve their performance as providers of welding services. In our Welding Advisers Site the following pages are available to interested readers:

8 - Site Updating: Contract Welding and Resources on the same subject The Pages of this Month deal with a problem that may come up unexpectedly at many shops working steadily using established welding routines. It may happen that an urgent need appears requiring unknown processes to be performed with equipment that is not available in house. Without renouncing to take the job, one can learn something useful and find out which benefits can be gained by sub-contracting that part of the work to a professional company, willing and able to perform it. Contract welding can be trusted to specialized welding activities having knowledge and experience with aspects of the profession that where not yet investigated in depth to determine if they are interesting opportunities for the shop. These companies my have the additional advantage of being already approved for demanding applications requiring official endorsement by the established authorities in charge of administering the safety provisions required. Some less common processes requiring unique equipment and dedicated professionals may be found at relatively small enterprises which flourish around their particular specialization. The introduction to this specialized welding activity can be found in the first Page of this Month at Contract-Welding. The second Page is a list of online references to real companies offering to perform specific work by sub-contract. It can be found at Bulletin 111. The webpages of the various providers advertise their equipment and their capabilities. No endorsement or recommendation is intended. Readers with first hand experience on subcontracting are invited to share their experience and their recommendations with this readership for helping those who may need some friendly help.

Nord Steam Pipeline - courtesy of Stroygazconsulting [From The real face of Russia:

9 - Short Items

9.1 - Elastic limit is the maximum stress that a material is capable of sustaining without any permanent strain (deformation) remaining upon complete release of the stress. 9.2 - Fatigue limit is the maximum stress that presumably leads to fatigue fracture in a specified number of stress cycles. The value of the maximum stress and the stress ratio also should be stated. 9.3 - Gas atomization is an atomization process whereby molten metal is broken up into particles by a rapidly moving inert gas stream. 9.4 - Heat check is a pattern of parallel surface cracks that are formed by alternate rapid heating and cooling of the extreme surface metal, sometimes found on forging dies and piercing punches. There may be two sets of parallel cracks, one set perpendicular to the other. 9.5 - Impression-die forging is one that is formed to the required shape and size by machined impressions in specially prepared dies that exert three-dimensional control on the workpiece. 9.6 - Jig boring is made with a single-point tool where the work is positioned upon a table that can be located so as to bring any desired part of the work under the tool. Thus, holes can be accurately spaced. This type of boring can be done on milling machines or jig borers.

10 - Explorations: beyond the Welder Why People Oppose GMOs Even Though Science Says They Are Safe Adaptive Headlights Could Help Drivers Avoid Hitting Bambi The Future of Sewage Is Power and Profits 3 Years into Its Mission, Curiosity's Stunning Martian Panorama Can Airlines Protect Passengers from Malfunctions and Misuse?

11 - Contributions: Nuclear grade amendment A kind reader with lots of experience in Welding Codes, Mr. Anthony Rangus, who reads attentively since many years back every word appearing in this publication, took issue with an innocent note written in our last Issue PWL#144, in section 9.2 saying that "Nuclear grade is Material of a quality adequate for use in nuclear application." For correcting the erroneous conclusion that less expert readers might derive from this assertion, he sent us the following contribution. "This is misleading. Take a look at all the allowed ferrous & nonferrous materials (plate, sheet, strip, bar, forgings, castings, pipe, tube etc. shown in ASME Section II Part D that actually state "for nuclear applications" as referenced for ASME Section III components.

You should steer clear of this type definition.

Granted, Templestik or Neolube and others may state "nuclear grade" as may other manufacturers.

But anyone can slap the term "nuclear grade" on their product. If you intended the "nuclear grade" to refer to ASME Section III and its additional requirements, or other similar foreign codes, for materials, then state that. Also be aware that "nuclear applications" could just as well refer to plutonium production, or tritium production at one of the DOE weapons complex facilities. Which are not necessarily built to ASME Section III." PWL thanks Anthony Rangus for his important contribution of precise information, and would be delighted to be able to publish other instructive notes reflecting his wide experience if he graciously sent us such items for publication. Our meager excuse is that the statement above was taken from a respected Glossary of Terms, with no ambition to establish binding Code rules. Curious readers may wish to learn more on the subject by seeking the page on

12 - Testimonials

On Sat Aug 01 22:05:53 2015, the following results were submitted from the "Form 5" on welding-advisers.com:

On Wed Aug 05 20:05:10 2015, the following results were submitted from the "Form 5" on welding-advisers.com:

13 - Correspondence: a few Comments We got a touching query from a lady asking advice on how to sell a welding business that no one in the family wants to take it on. It was said that it "is too big to be a small welding business, but not big enough to be a big business." I suggested a few organizations that advertise online their capability to help business sellers. But if any of the readers would like to know more about the subject, or might be interested in exploring more fully the issue, please send me a short note that I would forward to the person asking for help.

14 - Bulletin Board 14.1 - AWS 18th Annual Aluminum Conference. International Collaborative Robots Workshop. 27th National Robot Safety Conference. International Congress on Applications of Lasers &

ElectroOptics (ICALEO®). The Assembly Show.

Watch - The Video:

and also

Watch the following

POWERED BY: Click on this Logo NOW! Copyright © 2015, by Elia E. Levi and

See you next time...

|

||||||||||||||

| Back to Back Issues Page |