| Back to Back Issues Page | |||||||||||

|

|||||||||||

|

PWL#146, Traceability in Cutting, Economic Automatic Deburring, Filler Metal for GTAW 304L to 904L October 07, 2015 |

|||||||||||

| We hope you will find this Letter interesting and useful. Let us know what you think of it.

PWL#146 PWL#146 - Traceability in Automated Cutting, Economic Automatic Deburring, Filler Metal for GTA Welding 304L to 904L, Filling the Welders Workforce Gap, Additive Manufacturing and related Resources, Information from the Hardness Test and much more...

October 2015 - Practical Welding Letter - Issue No.146

Important Notice The Mid September 2015 Issue of Practical Welding Letter, Bulletin 112, dealing with online Resources on Additive Manufacturing (NEW) was not distributed by e-mail but it is available at Bulletin 112 and from the updated Welding Resources Page.

DON'T USE REPLY to send your messages! Use the Contact Us form instead. This publication brings to the readers practical answers to welding problems in an informal setting designed to be helpful and informative. You are urged to pass-along this publication to your friends, if you like it, and if you think they may enjoy it. The addresses reported hereafter were live and correct at the time of their publication. Note: References to articles or other documents are given here in one of two forms. If they are URL's (Uniform Resource Locator), which is the analogue of an address, they begin

with "http://..." or "www.". If the information is important to you as we hope, you may save the selected pages in a suitable folder on your Computer for easy reference.

1 - Introduction 2 - Article - Traceability in Automated Cutting 3 - How to do it well: Economic Automatic Deburring 4 - Filler Metal for GTA Welding 304L to 904L 5 - Online Press: recent Welding related Articles 6 - Terms and Definitions Reminder 7 - Article: Filling the Welders Workforce Gap 8 - Site Updating: Additive Manufacturing and related Resources 9 - Short Items 10 - Explorations: beyond the Welder 11 - Contributions: Information from the Hardness Test 12 - Testimonials 13 - Correspondence: a few Comments 14 - Bulletin Board

2 - Article - Traceability in Automated Cutting

Traceability is the capability to trace back to the origin, by means of documented recorded identification, all essential manufacturing and testing information on any of the elements being used in complex assemblies. This fundamental requirement is by now spelled out in all specifications and codes regulating fabrication and use of structures where failure might endanger human life. Traceability requires to exclude from assembly any item whose identification history is not documented in acceptable ways established by the relevant specification. The responsibility stands on the manufacturer who must be capable to demonstrate by collected and organized documentation that such obligations were met in full. An article published at page 48 in the September 2015 issue of the Welding Journal explains how integrated cutting systems set up to cut large plates of qualified materials in a crowd of individual cut parts permit to maintain traceability by imprinting on each part before cutting essential identification symbols. The article lists a number of steps to integrate the cutting process, to be established in order to assign to each cut part a unique identifier to be organized in a searchable database. The data to be recorded include a unique identifier assigned to each work order. Individual parts processed in the same cutting process work order receive an additional unique identifier. The import of data from the system to the nesting program should be automated. Each part geometry receives its description by a unique name including the drawing revision. For identical parts a serial number should be used for identification. Work order identifier and unique part identifier should be automatically imported to the system. To these data assembled for existing plates but also for remnants to be cut, one has to add the information of the plate manufacturer, material heat number, and other traceability information needed. The parts are nested on the material. The nest is given a unique identifier. The unique identifier of the material to be cut is taken from the plate database and written directly from the controller to the database of the nesting system. It is understood that all the data, possibly transferred automatically, are registered in the system. But, lacking an explicit mention of marking on the cut parts, I asked the author, Mr. Holger Hahn, who kindly answered as follows. "Marking of parts (unique number, QR etc.) is done in many possible ways. Essential is to mark each part individually. Parts on cutting machines are usually marked with inkjet, pin stamp or a printed label. That depends on the following production processes." Possibly also laser engraving could be employed, if it can be easily integrated in the system. Readers having to meet these requirements are urged to seek the original article mentioned above. Anybody's personal experience on the subject, which might add information to inquisitive doubtful readers is also welcome.

An integrated cutting system allows manufacturers to use traceability to realize additional

[From the Welding Journal, September 2015, page 48]

3 - How to do it well: Economic Automatic Deburring

Deburring may be needed after cutting in welding operations. An article published at page 56 of the September 2015 issue of the Welding Journal explains the advantages of switching from manual to automatic deburring. Among the claimed benefits are quality and productivity improvements together with reduction of health and safety issues for the workers. Also better process consistency is mentioned, important especially with high volume production lines. Stabilizing the upstream process as much as possible is the first tip towards successful automatic deburring, that should be built around the worst case. Processes made to serve too large a range of different parts may be more expensive and should be avoided. Where such variability cannot be reduced, a wear compensation system should be built to handle the natural wear of the media, especially if burr is changing over time. Material, geometry and part specification should be taken into account for selecting properly the deburring tool. It should be sufficiently large to make the system more robust. Suitable motor power is essential. The deburring cycle time should be shorter than the preceding and following processes, so as not to cause delays in the flow. Part orientation is an important consideration as is the unimpeded access of the brush wires to the burred edges. New vision systems permit to identify parts arriving randomly to the deburring station. In conclusion an optimized automatic deburring system can contribute to the success of the enterprise. Interested readers who need more details are urged to seek the original article mentioned above. 4 - Filler Metal for GTA Welding 304L to 904L

Anyone preparing to weld the above materials together should look for the Stainless Q&A note by Damian J. Kotecki published at page 22 in the September 2015 issue of the Welding Journal. The wealth of information displayed there is simply amazing. No hope to dig out of standard Handbooks all the explanations of mutual influence of different factors affecting the final result and its corrosion resistance in harsh service conditions. The note starts with the historic observation that the 904L alloy was first developed in France in the thirties, and then introduced in the US seventies for sulfuric-acid environments. It is classified as a nickel base alloy despite the fact that its iron content makes it more like a stainless. The Author makes the point that due provisions should be put in place to avoid full austenitic microstructure that would be prone to solidification cracking. Among them low S and P content both in base and filler metals, low heat input and elliptical weld pool shape. The regular suggestion of ER385 is acceptable for 904L welded to itself. But the Author warns against its selection if optimum corrosion resistance is required. Also the selection of standard ER308L, ER309L or ER316L filler metal is discouraged because of austenitic solidification cracking risk. The final suggestion, reached after examining the position of the weld in the WRC-1992 diagram (a later version of the famous Schaeffler's diagram) is for ER2209 duplex stainless steel filler metal, that would allow higher heat input and speed and would produce higher strength joints. In case of tearing during side bend test for qualification, the above Author suggests the use of a wrap around fixture, to reduce the tendency of this failure. Interested readers facing this or similar problems are urged to seek the original article mentioned above. 5 - Online Press: recent Welding related Articles Tata Steel unveils new welded product range Pemamek: Advanced Laser-Hybrid Welding Station Delivered Miller expands Continuum™ advanced industrial system offering, adds new process capabilities New welding apprenticeship standards receive government approval Changing trends in semi-automatic MIG guns 6 - Terms and Definitions Reminder Brazing Symbols specify, in conventional form, specific requirements relative to clearance, filler metal, heating methods and dimensions, including inspection method required. See AWS A2.4:2012 Standard symbols for Welding, Brazing, and Nondestructive Examination. Compressed Gas Cylinders are pressurized containers at 2500 psig used to handle gases used in welding and cutting operations. (Note: Acetylene cylinders are a special case). Deposited Metal, is metal that has been added to the surface in the process by welding or surfacing. Electrical Safety is the complex of precautionary measures designed to prevent personal injuries by electrical accidents. Electrical training must be provided by a competent professional. Flash time is the duration of flashing action during flash welding. Highway Bridges Welding Specifications AASHTO/AWS D1.5 contains the requirements for the welding of structural Steel highway Bridges. Liquid Penetrant Examination Procedures are included in Standard ASTM E165. Shielding Gases for welding are pure inert gases or mixtures often including not completely inert ones, like oxygen or carbon dioxide. 7 - Article: Filling the Welders Workforce Gap

Several sources have been admonishing for years now that a substantial gap is forming in the United States, and possibly all over the world, between the number of available skilled welders and the open vacancies likely to remain in need of being filled in the next decade. What seems to be happening though, is that the industrial field is changing at an accelerating pace, so that the quality and the traditional skills that used to be in demand, risk of not meeting anymore the actual requirements of new and developing technological levels. Under the market pressure and that exerted by advancing techniques, also the welders tasks to be accomplished are evolving, becoming more articulated and exacting. A welder, to be useful and required in modern industry, must be capable of dealing with the requirements of increasingly complex robotic welding cells, that may need a deeper and larger preparation with disciplines extraneous to welding proper as was described until recently. Young people are now exposed from their earliest youth to the wonders of electronic communication, so they are quick to grasp the mysteries of automatic controllers, and can master quickly and easily complex protocols used in modern instrumentation. Older people cannot compete adequately with learning new complex tasks. Not only the schools must be aware of the changes, but the individual trainees must be open to increased loads of knowledge and dexterity they must be willing and able to master in order to find their place in the manufacturing industries of tomorrow. More and more companies struggling with their way to prepare for an uncertain future, are opening internal courses and curricula offered at no cost to selected individuals with basic welding skills, to elevate their ability to cope with the demanding challenges likely to confront them during their working career. This is also a very attractive feature of modern welding craft, open to so many different and attractive specialties, giving to the curious and bold individuals unique unimaginable opportunities to find the best position for the fulfillment of their dearest wishes. The fact that this problem is felt in general, and possibly as a limiting factor in certain industrial segments, finds its expression in the September 2015 edition of the Welding Journal. There, three articles debate the questions: One, at page 34, titled "Educated Welders: the Real Employment Issue", by Dr. Jason Scales, manager of Educational Services, The Lincoln Electric Co., Cleveland, Ohio. It explains that the welders required in today's workforce are different from those of the past decades. Meanwhile the number of trained welders decreases, while talent shortage has an impact on business operations. Higher levels of specialization in equipment and applications are needed, but different construction needs in various environments require welding specialists with different skill sets. Both schools and employers find themselves in difficulty. A broad education is preferred, but a narrow specialization will provide employers with personnel capable of performing the specialized roles required. The level of education required for emerging technology must be advanced, and manufacturing companies should be ready to train workers for their peculiar requirements. The question is: "What do I need to do to allow my business to expand and grow?" Companies must be ready to invest substantial resources to improve the level of education of their workforce, as required for emerging technologies. Skill development is a hot topic not only in the public sector but in government as well. Grants are assigned on the national level to provide incentives likely to leave their mark on the results. The concept of lifelong learning and development, from initial training until retirement is being debated within partnerships between schools and industry, to prepare for future needs. The final thoughts of the author of the quoted article are: "We don't need entry-level welders who only know how to join two pieces of metal. We need our new people coming into the industry to have the skills today that would have been considered midlevel skills five or ten years ago. [...] we have to transform how we are educating our workforce to meet our long-term goals and to maintain a competitive edge on the world stage. The welding field is maturing into a diverse group of disciplines, and we need personnel with different education and skills than we did in the past". Another article at page 44, titled "Fabricator Takes on the Welder Shortage", by Melissa Gomez, assistant editor of the Welding Journal, reports on an actual initiative taken by a bold engineering and construction company in Texas, that started a preemployment welder upgrade training program. After realizing that nobody was offering the much needed upgrade, the company did not see this as a problem, but rather as an opportunity. It took the educational job upon itself, by building and operating its own training site. The trainees are screened before being accepted, but the whole training upgrade is offered them at no cost. Special welding booths were set up with modern equipment and facilities. The regular upgrading welding course runs now for 12 to 14 weeks. No special obligations are set for the trainees except to pass the upgrading tests. The company hopes to hire as many of the trainees as possible. The initiative is successful and a long list of candidate are on the waiting list ready to start training as soon as possible. Word of mouth seems to be the best advertisement: interviewed trainees expressed their satisfaction. A third article at page 52, titled "How Industry-Education Collaboration Can Address the Welding Skills Gap", by Timm Boettcher, president and CEO of Realityworks, Inc., Eau Claire, Wis., and chair of the Industry Workforce Needs Coalition, also addresses the welding skills gap. "To fill the skills gap with educated, qualified professionals, welding instructors and trainers (and instructors in other high-demand fields) need to use programs and technology that will engage today’s 21st Century students, provide them with hands-on opportunities to explore related career pathways, and train them efficiently and effectively." Such programs and technology can be found in career and technical education (CTE) programs. The author reviews some cooperative initiatives, like a mobile college on a truck-trailer that provides students from rural schools the opportunity to explore directly manufacturing technology and careers. Another example is described where industry experts give training programs participants leads to industry-recognized credentials and other help to enter the local job market, continue their education or both. There are many ways for industry to fund and support career-based curriculum development. Besides welding, there are several other high-demand careers where skilled trade jobs are the hardest to fill. To ensure that these training and education programs meet the needs, industry experts must work with business and education leaders. Collaboration will assure that more students will receive the education and training they need to succeed in high demand careers, and competitive jobs will be filled. Readers interested in these arguments are urged to seek the original articles, and to send us their feedback on how the competence gap affects their working environment.

Wisconsin’s Chippewa Valley Technical College collaborated with Realityworks,

Inc.,

[From the Welding Journal, September 2015, page 53]

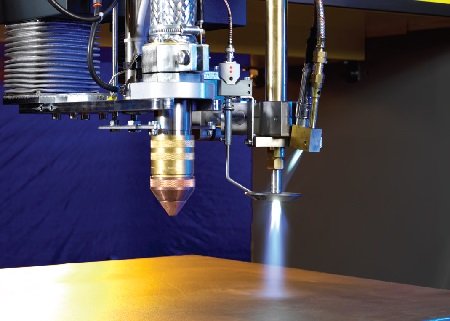

8 - Site Updating: Additive Manufacturing and related Resources The Pages of this Month revolve around a hot topic in quite different forms of fabrication, that will increasingly mark all types of production of the near future. Additive Manufacturing is by now a fact of life with exceptional achievements, albeit in the stage of rapid development. The website page can be found at Additive Manufacturing and the Resources Page at Bulletin 112. The webpages of the various providers advertise their equipment and their capabilities. No endorsement or recommendation is intended.

9 - Short Items

9.1 - Notch Brittleness is the Susceptibility of a material to brittle fracture at points of stress concentration. In a notch tensile test, the material is said to be notch brittle if the notch strength is less than the tensile strength of an unnotched specimen. Otherwise, it is said to be notch ductile.

9.2 - Oxidizing Atmosphere is that of a furnace with an oversupply of oxygen that tends to oxidize materials placed in it.

9.3 - Plasticity is the property of a material that allows it to be repeatedly deformed without rupture when acted upon by a force sufficient to cause deformation, and that allows it to retain its shape after the applied force has been removed.

9.4 - Quasi-Cleavage Fracture is a fracture mode that combines the characteristics of cleavage fracture and dimple fracture. An intermediate type of fracture found in certain high-strength metals.

9.5 - Resistance Seam Welding is a resistance welding process that produces welding at the faying surfaces of overlapped parts progressively along the length of a joint. The weld may be made with overlapping weld nuggets, a continuous weld nugget, or by forging the joint as it is heated to the welding temperature by resistance to the flow of electric current.

9.6 - Sectioning is the removal of a conveniently sized, representative specimen from a larger sample for metallographic inspection. Includes shearing, sawing, abrasive cutting, and electrical discharge machining.

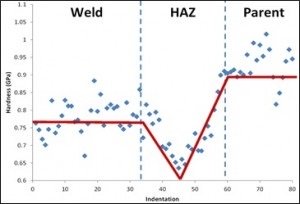

10 - Explorations: beyond the Welder How to Study 1 Million Patients' Medical Charts Graphene Gets a New Competitor Scientific American MIND Reviews Why We Work Firm in China Chemical Blast Skirted Safety Rules Pope Francis, Jimmy Carter and the "Greatest Threat to Peace" 11 - Contributions: Information from the Hardness Test As is widely known, the hardness test is simple and practical to perform. It actually describes the resistance to penetration of a well defined indenter under a specific load for a given time. The hardness value, expressed by a number in a scale, is derived from the resulting indentation. It should be remembered that the hardness is measured locally on the specific spot tested. If because of any causes the hardness is not uniform in the tested specimen, the result cannot describe the part as a whole. In general hardness results are often representative of strength, within limits of approximation. Metallurgical changes due to welding can be interpreted by the measured hardness changes. In alloy steels, high hardness could indicate the presence of untempered martensite, which might be objected as dangerous in certain situations. Low values might indicate overtempered conditions where the strength is lower than acceptable. In work hardened materials, welding may reduce strength as heat causes recovery and recrystallization. In materials heat treated by solution hardening and tempering, welding may cause overaging and reduction of strength. Series of hardness indentations performed on a welded specimen ground and polished, in specific directions and at given distances, give a picture of the hardness distribution in and around the weld. The information gathered from such a picture can help improving the welding process. Readers are reminded here that they can download at no cost a book on Practical Hardness Testing made Simple, by just subscribing to this publication.

Figure 3: Change in nanoindentation hardness across a P92 matched weld at 675 °C.

[from Nuclear Materials

12 - Testimonials On Thu Sep 03 01:50:04 2015, the following results were submitted from the "Form 5" on welding-advisers.com: Name: Chris Boone

On Fri Sep 18 11:58:56 2015, the following results were submitted from the "Form 5" on welding-advisers.com: Name: Doug Kautz

13 - Correspondence: a few Comments Many of the questions reaching my desk are already answered in several of our pages or other publications. Where the answer need more specific approach, the question should be generally more detailed with complete explanations on the specifics of the case. At the top of our contact us form we ask for a preliminary search through the wealth of our published material. It is suggested to start with checking the Site Map in search for specific website pages. Then a check of the FAQ Pages may find out what is needed. Additionally by browsing through Welding Topics Page one could find if the issue was treated in the past in this periodic publication. Finally by performing a Search in the special window appearing in almost every page of our website, one can be addressed to several places of this website where the question is already answered. 14 - Bulletin Board 14.1 - 27th National Robot Safety Conference. 14.2 - International Congress on Applications of Lasers &

ElectroOptics (ICALEO®). 14.3 - The Assembly Show. 14.4 - FABTECH 2015

SBI! E- Business - Building An Online Business

Watch - The Video:

and also

BUILT BY: Click on this Logo NOW! No better way to get to know SiteSell, Specific questions about SiteSell?

Copyright (©) 2015, by Elia E. Levi and

See you next time... |

|||||||||||

| Back to Back Issues Page |