| Back to Back Issues Page | |||||||||||||

|

|||||||||||||

|

PWL#149, Virtual Welding Simulators, Remote Control, Proper steel filler, new welding technique January 04, 2016 |

|||||||||||||

| We hope you will find this Letter interesting and useful. Let us know what you think of it.

PWL#149 PWL#149 - Evaluating Skills with Virtual Welding Simulators, Remote Control Welding Technologies, Steel Filler Metal appropriate for the Base Metal, Vaporizing Foil Actuator Welding (VFAW) new welding technique, Weld Quality and Resources, Tips for small Welding Businesses and much more...

January 2016 - Practical Welding Letter - Issue No.149

Important Notice The Mid December 2015 Issue of Practical Welding Letter, Bulletin 115, dealing with online Resources on Welding Quality (NEW) was not distributed by e-mail but it is available at Bulletin 115 and from the updated Welding Resources Page. DON'T USE REPLY to send your messages! Use the Contact Us form instead. This publication brings to the readers practical answers to welding problems in an informal setting designed to be helpful and informative. You are urged to pass-along this publication to your friends, if you like it, and if you think they may enjoy it. The addresses reported hereafter were live and correct at the time of their publication. Note: References to articles or other documents are given here in one of two forms. If they are URL's (Uniform Resource Locator), which is the analogue of an address, they begin with

"http://..." or "www.". If the information is important to you as we hope, you may save the selected pages in a suitable folder on your Computer for easy reference.

1 - Introduction 2 - Article - Experience with Virtual Welding Simulators 3 - How to do it well: Remote Control Welding Technologies 4 - Choosing a Steel Filler Metal appropriate for the Base Metal 5 - Online Press: recent Welding related Articles 6 - Terms and Definitions Reminder 7 - Article: VFAW - A new welding technique to watch 8 - Site Updating: Weld-quality and Resources 9 - Short Items 10 - Explorations: beyond the Welder 11 - Contributions: Tips for Small Businesses 12 - Testimonials 13 - Correspondence: a few Comments 14 - Bulletin Board

2 - Article - Experience with Virtual Welding Simulators

Virtual-Welding-Simulators are machines used for learning and training welding skills. Virtual reality or computer-simulated reality, replicates an environment that simulates a physical presence in space in the real world or in an imagined world, allowing the user to interact in that world. Virtual realities artificially create sensory experiences, which can include sight, hearing, touch, and smell. Initially it was developed for computer games, producing visors and screens, stereo headphones and inertia sensors. Outside of the welding profession, virtual reality has been widely used for training drivers and pilots. Successful training programs for medical use, employ a surgery simulator, based on computer technology, to offer the opportunity to perform virtual surgical procedures, for the purpose of training medical professionals before resorting to actual practice. We briefly mentioned Virtual-Welding-Simulators and their use in PWL#093, in PWL#096, and occasionally provided links to articles and commercial publications on the subject. A recent article, published in the December 2015 issue of the Welding Journal at page 389-s reports on "The Use of Virtual Welding Simulators to Evaluate Experienced Welders". In this article a known system from a commercial manufacturer was used to test if its use could provide a way to assess the actual skill of experienced welders. Assessment of tasks requiring skill can be performed using virtual reality trainers because simulations can be recorded and analyzed. A potential advantage of virtual reality simulation is the ability to measure technical competence using software programming to analyze performance. The conclusions of the study was that simulators properly programmed can indeed provide an objective and unbiased independent evaluation to help in screening job seeking welders, by assigning scores to their performance. The researchers suggest to continue to investigate the subject by performing follow-up studies to validate the findings. Interested readers facing the necessity to test and grade applicants to welders' positions in the industry may benefit from the reported study by looking into the above mentioned article, dowloadable from:

https://app.aws.org/wj/supplement/WJ_2015_12_s389.pdf

Was this article useful? Your feedback is welcome.

Simulated Welds completed by participants.

3 - How to do it well: Remote Control Welding Technologies

For certain types of construction where the power source is located far from the point of welding, it appears that recent profitable developments are now available. While the operation details may differ for different solutions, the advantages advertised include complete parameters setting and control at the welder's end, eliminating trips to and from the source and reducing risk of tripping and falls, increasing arc-on time, improving profitability and promoting jobsite safety. In the past, some devices involved the use of an extra cable for managing the controls, but this is discouraged in modern solutions that consider it an extra cost both for purchasing and for maintaining. Wireless controls are offered which may be adequate if the distance is not excessive and if the line of sight is not obstructed. Some solutions run the control signals on the power cables avoiding additional accessories. Interested readers who may wish to explore more in depth these modern remote control technologies for welding, can find a few articles on this subject in the press, albeit written by equipment manufacturers, who may offer biased suggestions. One of these can be found in the December 2015 issue of the Welding Journal at page 32. They could also ask their suppliers to inquire which solutions are offered. Readers with practical personal experience with the technology are invited to share it here.

Converting to flux-cored and advanced wire welding processes.

4 - Choosing a Steel Filler Metal appropriate for the Base Metal

Where can we find a guide to selecting a Steel Filler Metal appropriate for the Base Metal? An Article on this subject was published in the April 2015 issue of the Welding Journal at page 52. In case such a question is likely to come up sooner or later, it would be wise to keep this reference handy for the time when it may be needed. As more than one filler metal may be appropriate for any given case, one should note that other factors could play a role in the selection, like welding process, welding position, plate thickness, plate surface condition, electrode size and packaging. Low carbon steels include those of 0.05-0.30% carbon, Medium carbon steels those of 0.30-0.45% C, High carbon steels those of 0.45-0.75% C. While low carbon steels have good weldability and can normally be welded with many different filler metals and welding procedures without problems, medium to high carbon steels have poorer weldability and produce more crack sensitive welds. See the Lincoln Electric Filler Metal Selector Guide downloadable from: One important consideration that is frequently brought up is that of matching minimum tensile strength. Exact correspondence is not required, but the filler metal’s minimum tensile strength should be at least as high as that of the base metal. When welding together two steels of different strength it is recommended to select a filler matching the strength of the weaker of the two. The lower strength filler metal would provide such benefits as better ductility, improved weldability, and lower cost. Sometimes one can compensate for the reduced strength of the filler metal by increasing the section of the weld performed, beyond the strict minimum. This practice is called overwelding with undermatching filler metal. Preheat is needed in general for carbon content higher than 0.30% or for Hardness equal to or higher than 30 HRC. Post Weld Heat Treatment (PWHT) may be needed too in those cases. For high strength steels one should specify low hydrogen filler metals to reduce susceptibility to cracking. Requirements for filler metals exhibiting minimum Charpy V-notch (CVN) test value at given low temperatures are spelled out in certain Codes. If stress relieving is required, it may reduce the weld strength. To maintain the strength required from the structure, one may need to use low alloy steel filler metals instead of low carbon steel. Special requirement steels like weathering steels, low alloy steels and quenched and tempered steels may need special consideration that cannot be adequately covered in this short note. In conclusion the properties required from the structure to be welded (to perform adequately in service) will condition the choices available in the selection of appropriate filler metals. Interested readers in need of additional information are urged to seek the original article quoted above.

These tensile specimens represent examples of relative high and low ductility. 5 - Online Press: recent Welding related Articles Automated Welding for Making Custom Exhaust Snake-Arm Robot Welds with Lasers VIDEO: Industrial Robotics Simplifying the Welding Process Techniques for determining the effect of a sour environment on fracture toughness of steel Robotic arc welding Connect - Issue 12 - November/December 2015 6 - Terms and Definitions Reminder Adaptive control welding is done with a process control system that automatically determines changes in welding conditions and directs the equipment to take appropriate action. Backing back pass is a weld pass resulting in a back weld. Cold soldered joint results from incomplete coalescence caused by insufficient application of heat to the base metal during soldering. Design for welding primary objectives are to produce an assembly that performs the intended functions, has the required reliability and safety, and can be fabricated, inspected, transported and placed in service at minimum cost. Energy input is the quantity of energy applied per unit length of weld expressed in joules per meter or equivalent Fitter is a worker whose task is to fit the workpieces in preparation for welding. Gas Standards are regulatory specifications concerning properties, manufacture, transportation, storage, handling and safety procedures emitted by the (US) Compressed Gas Association (CGA), for gases used in the welding industry. Hydrogen Brazing is a nonstandard term used to indicate brazing in a hydrogen atmosphere. 7 - Article: VFAW - A new welding technique to watch

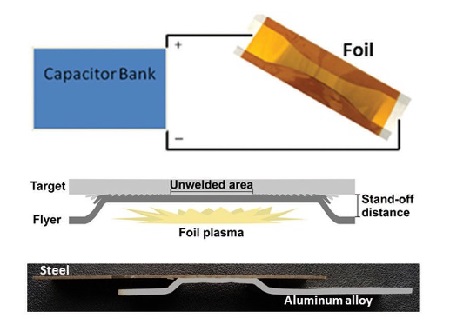

A short note, published at page 14 in the December 2015 issue of the Welding Journal, briefly introduces a new welding technique developed by engineers at The Ohio State University. It is worth watching because, after being properly commercialized, it could have a major impact on the automotive industry, as it is intended to weld together dissimilar metals, like high strength new steels and strong aluminum alloys, that are considered unweldable by current processes. Called Vaporizing Foil Actuator Welding (VFAW), this cold welding process produces welds similar to those obtained by explosion welding but in a laboratory setup, far from the dangers of working with explosives. A high-voltage capacitor bank creates a very short electrical pulse of high current inside a thin piece of aluminum foil. Within microseconds, the foil vaporizes, and a burst of hot gas pushes two pieces of metal together at very high speeds. The impact joins the two metals together, resulting in strong bonds. Upon testing, the failure occurs in the unaffected metals, not in the weld. Several materials combinations were successfully welded by this technique, where regular fusion welding would have produced unacceptable brittle intermetallic compounds. The aim of the development is to achieve automatic production of spot welds right in the assembly line of vehicle manufacturing. In another publication the author describes the characteristics of VFAW as follows: Low Energies needed, High Versatility, High Joint Efficiency, Great Joint Properties without heat affected zone, and possible Automation. Interested readers are urged to watch the following videos. Vaporizing Foil Actuator Welding by Collision of Dissimilar Metals

VFAW State of the Art November 2015

This diagram shows vaporized foil actuator welding.

8 - Site Updating: Weld-quality and Resources What are the Pages of This Month? By the way, why would not you try to come up with suggestions as to which subjects would you like to see explored in new pages? You are warmly invited to take some bits of your precious time to think over this! And to send us your ideas by the form at Contact Us. Thanks. Back to this (or better - last) month: the subject dealt with is Weld quality, a big item upon which stands most of the success of welding technology. The page reminds what supports our happy hopping on modern aicraft, our careless use of elevators, our confident driving of modern cars, and practically whatever we do. It may be useful to remind from time to time basic concepts that we may take for granted, but that in the practice of every welding job must be constantly present and monitored. The page in question is found at Weld-quality. And the list of links to useful online sources on the same subject is available in the Bulletin 115 page. Your comments and feedback are always welcomed. 9 - Short Items

9.1 - Green Sand is a naturally bonded sand, or a compounded molding sand mixture, that has been mixed with water and that is used while still moist. 9.2 - Hall Process is a commercial process used for winning aluminum from alumina by electrolytic reduction of a fused bath of alumina dissolved in cryolite. 9.3 - Impact Extrusion, also called cold extrusion, is either the process or the product in which a punch strikes an unheated slug in a confining die. The metal flow may be either between punch and die or through another opening. 9.4 - Linear Strain is the change per unit length, due to tensile or compressive force, in an original linear dimension. An increase in length is considered positive. 9.5 - Minimum Bend Radius is that over which a metal product can be bent to a given angle without fracture. 9.6 - Notch Depth is the distance from the surface of a test specimen to the bottom of the notch. In a cylindrical test specimen, the percentage of the original cross- sectional area removed by machining an annular groove.

10 - Explorations: beyond the Welder Why 2016 Could Be a Watershed Year for Emotional Intelligence--in Machines

The Science to Look Out for in 2016

So Your Neighbor Got a Drone for Christmas

Potential New Particle Sparks Flood of Theories

Archaeological Finds in El Salvador Tell a Whole Different Tale about Maya Society

11 - Contributions: Tips for Small Businesses

An article with the above title was published at page 36 of the December 2015 issue of the Welding Journal. The author interviewed the winners of a Small Business Awards contest comparing the achievements of welding shops, for the last five years. The winners were asked about the most significant aspects contributing to their success in today's economy. The answers identified different challenges, but their core issue was the same: strategic focus was singled out as their most important issue. One must find out one's core competencies and concentrate the efforts around projects that can forward the business: know what you do best, and stick to that product or service. Try to solve customer's problems at a faster lead time than the competitors. Deliver outstanding results whenever your customers needs. Make every product something the whole company can be proud of. If you only have one brand of product, this helps you keep a unique identity. Focus on more difficult projects that the competition veered away from. Some of the inquired stressed the importance of a strong website and the implementation of social media for increased communication with customers. Financial tips start with the need of an accountant and a bank that one feel comfortable with. Costs and workforce are common subjects that need attention. Know your customers needs ahead of time. Let them know that you follow personally their project. A capable and dedicated team is essential to the business success. These and other hints and suggestions appear in the article above that interested readers are urged to seek, to gather the most out of the experience of successful welding shops. The comments of experienced shop owners are welcomed for our readership. 12 - Testimonials On Fri Dec 04 05:27:13 2015, the following results were submitted from the "Form 5" on welding-advisers.com: Name: BOB EDWARDS On Tue Dec 08 12:04:44 2015, the following results were submitted from the "Form 5" on welding-advisers.com: Name: Hector Bernal 13 - Correspondence: a few Comments Looking for a new job? Readers

interested in checking for themselves, can obtain the list

by sending a request to: 14 - Bulletin Board ShipTech 2016. FABTECH Canada.

9th International Seminar & Conference on Advances in Resistance Welding. No Commute = Less Stress

Watch - The Video:

and also

BUILT BY: Click on this Logo NOW! No better way to get to know SiteSell, Specific questions about SiteSell?

Copyright (©) 2015, by Elia E. Levi and

See you next time... |

|||||||||||||

| Back to Back Issues Page |