| Back to Back Issues Page | |||||||||||||

|

|||||||||||||

|

PWL#151, Follow-up on VFAW, Brazing Titanium Tips, HP Cold Al Spray, Active Diffusion Bonding of SS March 01, 2016 |

|||||||||||||

| We hope you will find this Letter interesting and useful. Let us know what you think of it.

PWL#151 PWL#151 - Follow-up on Vaporizing Foil Actuator Welding, Limiting interaction for Brazing Titanium, High Pressure Cold Spray of Aluminum wire for Magnesium Castings Repair, Active Diffusion Bonding for brazing stainless steel without brazing filler metal, Laser Surface Patterning Pre-Treatment for Plasma Spray, Metal Knowledge and the making of a Metals Encyclopedia and much more...

March 2016 - Practical Welding Letter - Issue No.151

Important Notice The next Mid Month Bulletin will be published as soon as possible. It will contain a revised edition of the Metals Encyclopedia - Vol. 1, as announced further down this page (8) in our page on Metals Knowledge.

DON'T USE REPLY to send your messages! Use the Contact Us form instead. This publication brings to the readers practical answers to welding problems in an informal setting designed to be helpful and informative. You are urged to pass-along this publication to your friends, if you like it,

and if you think they may enjoy it. The addresses reported hereafter were live and correct at the time of their publication. Note: References to articles or other documents are given here in one of two forms. If they are URL's (Uniform Resource Locator), which is the analogue of an address, they begin with "http://..." or "www.". If the information is important to you as we hope, you may save the selected pages in a suitable folder on your Computer for easy reference.

1 - Introduction 2 - Article - Follow-up on VFAW 3 - How to do it well: Brazing Titanium 4 - Aluminum Filler Metal for High Pressure Cold Spray of Magnesium Castings. 5 - Online Press: recent Welding related Articles 6 - Terms and Definitions Reminder 7 - Article: A new method of brazing stainless steel parts 8 - Site Updating: Metals Knowledge 9 - Short Items 10 - Explorations: beyond the Welder 11 - Contributions: Laser Surface Patterning Pre-Treatment 12 - Testimonials 13 - Correspondence: a few Comments 14 - Bulletin Board

2 - Article - Follow-up on VFAW

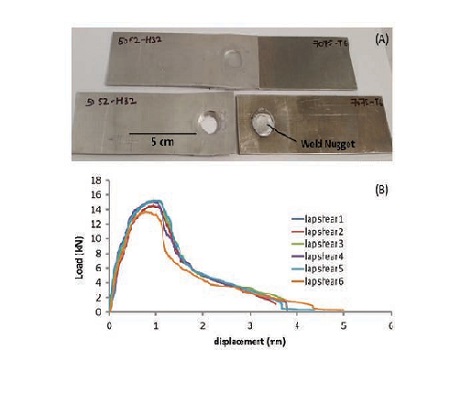

Our readers already had the opportunity to be informed by a short note, published in PWL#149, column (7), on a novel impact welding technique likely to be developed into automatic welding applications for automotive mass production. An article published at page 32 of the February 2016 issue of the Welding Journal, illustrates VFAW of aluminum Alloys A5052 and A7075. It explains again the process in detail and remarks that it may be important in the automotive industry toward approaching vehicle weight reduction. As already mentioned in the previous published note, the process called Vaporizing Foil Actuator Welding (VFAW) is an impact cold welding technique which imparts to the joints characteristic wavy morphology similar to those of Magnetic Pulse Welding (MPW) and explosive welding, but without the dangers of using explosives. It utilizes the force generated by a thin aluminum foil vaporized by a high electric current to launch one piece of metal toward one or more stationary target sheets. The results are similar to those of oblique impact between flyer sheet and target plates, leaving microscopic irregularities that contribute to the metallurgical bond, without any loss of mechanical properties due to heat. The quoted article describes the setup in detail and the test conditions. Overlapping test specimens of the two aluminum alloys investigated were spot welded and then subjected to shear testing, micro hardness and imaging. Microhardness results show that it was held constant at the base material level on both sides of the weld interface and around the weld nugget. The samples failed outside the weld nugget at an average load of 14.5 kN. The average nugget diameter was 10 mm. As compared to friction spot welds and resistance spot welds (both of which develop substantial heating) between similar materials, the welds created by VFAW are roughly twice as strong. This is not surprising as no heat was involved to reduce hardness and strength. The article attributes the results to three factors: 1) negligible thinning around the welded area, 2) no Heat Affected Zone (HAZ), and 3) very effective metallurgical joining at the bond line. The research group at The Ohio State University has recognized the following three main areas for improvement and is actively working on them: Automation, fixturing and noise reduction/handling of fumes. The conclusive remarks are reported hereafter: "Although significant effort is required for full-scale industrial implementation of this technology, early signs show that VFAW can play an important role in the world of joining". Readers interested in following-up on this technology are urged to seek the original article quoted above.

A - A5052/A7075 VFAW spot welded samples before and

after lap shear testing 3 - How to do it well: Brazing Titanium

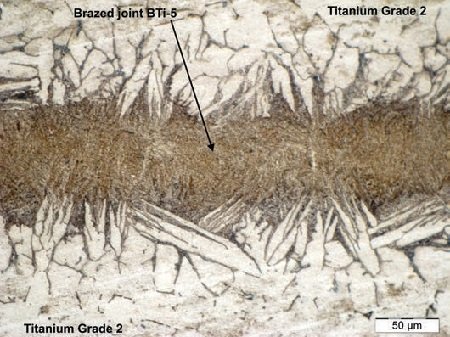

The regular Brazing Q&A column published in the February 2016 issue of the Welding Journal at page 24 deals with brazing Titanium Grade 2. The inquirer had difficulties in obtaining satisfactory results in his vacuum brazing attempts using a standard BTi-5 filler metal. In particular he had found large strength spread among specimens brazed for different length of time. The brazing expert answering to the question, Alexander E. Shapiro, remarks that the constituents of the filler metal (Cu, Zr, Ni) are characterized by high reaction ability and intense diffusion exchange during interaction with base metals and form brittle intermetallic phases. The fractured brazed joints occur in the intermetallic layer at the interface with the base metal. Only if the joint is very thin the brittle layer is not allowed to grow thick and dangerous. Therefore, the first recommendation of the article is to avoid large fillets, to assure quality and reliability of titanium brazed joints. It goes on, commenting that thermal cycles play an important role in optimizing the microstructure. Two approaches are adopted to change the thermal cycles, but the first, involving additional diffusion and aging is not discussed there as it requires separate consideration. Limiting the reaction time while also decreasing the temperature to the minimum is recommended, but it requires experimentation with the actual parts and brazing set-up, to find the optimal holding time for each selected temperature. Interested readers are invited to seek the original article indicated above.

Microstructure of Ti Grade 2 joint <50 microns thick brazed by BTi5 filler metal at 890°C for 10 min. [From the Welding Journal, February 2016 - page 25]

4 - Aluminum Filler Metal for High Pressure Cold Spray of Magnesium Castings.

An article excerpted from Tim Eden's contribution to "High Pressure Cold Spray: Principles and Applications", a new book from ASM to be published in May, throws new light on a process used to restore corroded magnesium castings used in aircraft applications. The article, titled "Magnesium repair on Lightweight aerospace Components" is published at page 10 in the February 2016 issue of International Thermal Spray & Surface Engineering (iTSSe), the official Newsletter of the ASM Thermal Spray Society, and distributed as an insert in the February 2016 issue of Advanced Materials and Processes (AM&P), a publication of ASM International. The article explains that magnesium alloy castings are frequently preferred for their structural strength combined with light weight, in weight critical applications, especially in helicopters. Unfortunately they have a very high anodic index, meaning that they are electrochemically active and prone to galvanic corrosion when coupled with another metal. Suitable coatings are used to insulate magnesium from other metals. However, when the coating deteriorates, corrosion starts and develops quickly. Welding repair, although possible in principle, is seldom used in practice due to severe limitations. Any alternative process not based on heat application is easily preferred, provided it is acceptable by engineering as fit for the purpose. The quoted article lists the benefits of the process indicated, essentially permitting restoration of scrapped parts, making them acceptable for further usage. Details on the process, not given in the article, will be explained in the book to be published. The above publication is downloadable from :

Micrograph shows commercially pure aluminum applied via high pressure cold spray. 5 - Online Press: recent Welding related Articles AweSim Project at OSC to Advance Welding Simulation Transforming Welding with Comprehensive NIST Metrology Thinking about submerged arc welding? No such thing as too

safe TWI Connect - January February 2016

6 - Terms and Definitions Reminder Aligned Porosity is a localized array of porosity oriented along a line. Composite is a complex material consisting of two or more discrete materials, thoroughly intermixed, each of which retains its physical identity. Electrode Tip is the end of a resistance spot welding electrode making contact with the workpiece. Groove Angle is that included between the groove faces of a weld groove. Interpass Temperature in welding is the temperature of the weld area between weld passes in a multipass weld. Keyhole Welding is a technique in which a concentrated heat source penetrates partially or totally through a workpiece, forming a keyhole at the leading edge of the weld pool. Metal Transfer Mode is the form or the way in which molten metal is transferred from the end of a consumable electrode across the welding arc onto the workpiece. Preheat is the heat applied to the base metal prior to welding to reach and maintain a specified preheat temperature. 7 - Article: A new method of brazing stainless steel parts

A new method of brazing stainless steel parts is briefly introduced at page 50 of the February 2016 issue of the Welding Journal. It is about a technology developed and patented by Alfa Laval Corp., Lund, Sweden. Unfortunately, further search at the Company website did not reveal any additional technical details on the process. This however is described as a unique active diffusion bonding technology patented by Alfa Laval, known as AlfaFusion technology. Obviously the process was developed to support one or more of the special products of the company, namely AlfaNova fusion-bonded heat exchangers. One of the company's publications describes the product as follows: From the WJ note, that is not accompanied by any list of References, one learns that "The method proved that it is possible to create a melted alloy of the parent material by using a Mn3P2 or NiP and pure silicon powder mixture as a melting point depressant on the plate surface in vacuum or in a hydrogen atmosphere. No additional brazing filler metal is used." According to the WJ note, specific powders are mixed with a water-based polymer binder to form a paste, and are placed onto the flat surface of a 316 stainless steel part. The details are not explained but is seems that the parts, covered at the joints emplacements by any of the two depressants, have to be conditioned by heat treatment for 2 h in vacuum at 1120°–1140°C. Any further details are missing, except for the comment that the formed joint alloy after cooling has a composition similar to the base metal. It can only be imagined that following the heat treatment described, either in the same or in a subsequent set-up, some pressure is applied to drive the diffusion bonding at some selected temperature. Interested readers who may wish to consider if the process might solve any of their production problem should apply to the company for licensing the process. Readers who may wish to add details they know are invited to share their experience. 8 - Site Updating: Metals Knowledge The Page of this Month was inactive for a long time. It was originally intended to provide readers with authoritative welding information. The idea was to publish online links to reputable sources whose publications could be the core of a Metals Encyclopedia to be assembled at no cost by anyone interested, as a repository of information readily accessible in files saved on one's computer. Two electronic volumes in printable format were offered for a modest price, and several readers profited from the material made available, and downloaded whatever they deemed useful, as printed information from many sources. Reliable information is still needed by those working on welding. The two original volumes will undergo update and revision, and will be made available in a short time, at no cost, to all interested. They are going to be published as Mid Month Bulletins. The above page Metals-Knowledge was rewritten, and it will be updated as soon as the Bulletins are published. In the meantime readers are urged to explore a similar publication of this website, the page on Welding Resources listing the subjects already dealt with, and growing in time. We hope that readers find what they need, and everyone is invited to write us their questions, using the Contact Us form. For orientation, the Site Map is probably a good place to start from.

9 - Short Items

9.1 - Basic Steel is that melted in a furnace with a basic bottom and lining and under a slag containing an excess of a basic substance such as magnesia or lime. 9.2 - Catalyst is a substance capable of changing the rate of a reaction without itself undergoing any net change. 9.3 - Dewaxing in casting, is the process of removing the expendable wax pattern from an investment mold or shell mold, usually accomplished by melting out the wax with the application of heat or dissolving it with an appropriate solvent. 9.4 - Elastic Deformation is a change in dimensions directly proportional to and in phase with an increase or decrease of the applied force. 9.5 - Ferromagnetic Material is one that in general exhibits the phenomena of hysteresis and saturation, and whose permeability is dependent on the magnetizing force. Microscopically, the elementary magnets are aligned parallel, in volumes called domains. 9.6 - Grain Coarsening is a heat treatment that produces excessively large austenitic grains in metals.

10 - Explorations: beyond the Welder Gravitational Waves Discovered from Colliding Black Holes Did Global Warming Slow Down in the 2000s, or Not? Can Kids Learn More When They Exercise During Lessons? Negative Emotions Are Key to Well-Being Exoplanet Census Suggests Earth Is Special after All 11 - Contributions: Laser Surface Patterning Pre-Treatment

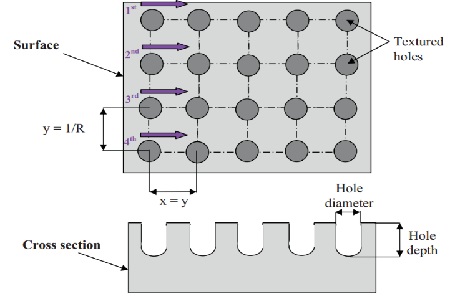

An article briefly mentioned in iTSSe (see 4 above) and published in ITSC 2015 — Proceedings of the International Thermal Spray Conference, is available for purchase ($15) from ASM International. Its complete title is: The article reports on research work that studied the application of a fiber laser to create micro-patterning on metallic surfaces in order to promote coating adhesion. The use of grit blasting for creating a uniform roughness risks of damaging delicate surfaces and of leaving contamination on the surface to be sprayed on. Lasers tools employed for conditioning have been shown to improve surface behavior of materials as surface treatment techniques for cleaning purposes, topography modification and preheating. Laser advantages can be summarized in its flexibility, adaptable to the most diverse situations. In the study reported, the laser application was used to create a pattern of fine holes regularly distributed on the surface, to provide anchoring points to the splat particles of thermal spray. In the conclusions it is affirmed that textured surface with optimized keyhole morphology permits to obtain a higher adhesion value, about three times that observed with conventional pretreatments. Interested readers wishing to improve the adhesion results of their applications of thermal spray may benefit from studying the quoted article indicated above.

Shallow Spot-Shape Cavities [From ITSC 2015—Proceedings of the International Thermal Spray Conference May 11-14, 2015 - page 121]

12 - Testimonials From Alain Juhasz February 3rd, 2016 Hello Elia, You are a trusted source of welding advice like there is no equivalent on the net, I want to thank you for sharing your knowledge and passion so consistently with your readers over the years, and I am sure you don't fully

realize how much help you are to the welders out there. Thank-you Alain

13 - Correspondence: a few Comments You may recall that in the last issue, following a request of a skeptic reader, I asked virtually trained welders to kindly express their appreciation of the new training technology, to let us learn from their experience. Either no such trained welders are in our readership or else they are too busy to let us know their remarks. The sad fact remains that not a single reader wrote us to comment on the effectiveness of virtual welding training. That was what I feared to begin with. Too bad, for us and for curious readers. Sorry! 14 - Bulletin Board 14.1 - FABTECH

Canada 14.2 - International Conference on Plastic Welding and Joining 14.3 - International Laser Technology Congress AKL ’16. 14.4 - 18th International Symposium on Zirconium in the Nuclear Industry SBI! E-Business - Building An Online Business

Watch - The Video:

and also

BUILT BY: Click on this Logo NOW! No better way to get to know SiteSell, Specific questions about SiteSell?

Copyright (©) 2016, by Elia E. Levi and

See you next time... |

|||||||||||||

| Back to Back Issues Page |