| Back to Back Issues Page | |||||||||||||

|

|||||||||||||

|

PWL#152, Bridge Welding Code New Issue, Testing Auto Composites, Spec Fine Print,monitor laser power April 01, 2016 |

|||||||||||||

| We hope you will find this Letter interesting and useful. Let us know what you think of it.

PWL#152 PWL#152 - AWS D1.5, Bridge Welding Code new edition, New ways to test Automotive Composites, Read fine print to avoid Qualification issues, New way too measure real time welding laser power, Minimizing Titanium alpha case, first release of links to build online Encyclopedia and much more...

April 2016 - Practical Welding Letter - Issue No.152

Important Notice Check the New Mid March Bulletin including Resources on Metals, Part 1.

DON'T USE REPLY to send your messages! Use the Contact Us form instead. This publication brings to the readers practical answers to welding problems in an informal setting designed to be helpful and informative. You are urged to pass-along this publication to your friends, if you like it, and if you think they may enjoy it. The addresses reported hereafter were live and correct at the time of their publication. Note: References to articles or other documents are given here in one of two forms. If they are URL's (Uniform Resource Locator), which is the analogue of an address, they begin with "http://..." or "www.". If the information is important to you as we hope, you may save the selected pages in a suitable folder on your Computer for easy reference.

1 - Introduction 2 - Article: AWS D1.5, Bridge Welding Code new edition 3 - How to do it well: Testing Automotive Composites 4 - Duplex Stainless Filler Metals and Procedure Qualification Problems 5 - Online Press: recent Welding related Articles 6 - Terms and Definitions Reminder 7 - Article - A new way to measure Laser Power 8 - Site Updating: Bulletin_117 with Resources on Metals, Part 1 9 - Short Items 10 - Explorations: beyond the Welder 11 - Contribution: Minimizing Alpha Case 12 - Testimonials 13 - Correspondence: a few Comments 14 - Bulletin Board

2 - Article: (AWS) D1.5, Bridge Welding Code new edition

The Editorial, published at page 6 in the March issue of the Welding Journal, highlights changes and improvements introduced in the new edition of the AASHTO/AWS D1.5 Bridge Welding Code. Huge changes and significant improvements to welding procedure qualification rules and a new nondestructive examination method are announced. The article considers that years of experience under the older code demonstrated that the right time came to simplify qualification rules. So a single pass groove weld qualification test piece is no longer required for single pass fillet weld procedures. There will also be more flexibility in use of consumables designed for fillet welds, such as active fluxes for submerged arc welding. That is because it was found that active flues react with voltage to improve weld metal strength, which is a welcome consequence. But the older rule requiring grove weld test for qualification precluded their use, because in multi pass welds the alloys build up makes the weld metal brittle, so that some of the best techniques for fillet welding were not available. Experience permitted to simplify the rules regulating heat input to help qualify an acceptable range of welding parameters by removing additional restrictions on additional voltage and amperage variation constriction. The production procedure method requires that the actual parameters to be used in the work should prove they can pass testing, removing additional limitations. The new code adopts optional phased array ultrasonic testing (PAUT) to keep up with advancement in technology, offering significant advantages. The author who, as vice chair of the committee took part in the preparation of the new edition, considers that it takes great steps forward in welding procedure qualification and nondestructive examination and invites users to provide feedback.

3 - How to do it well: Testing Automotive Composites

Most metallurgists who learned the trade years ago (like myself), know the classic metal testing methods used in a well equipped laboratory to validate or investigate the mechanical properties of metal parts. Unfortunately though, that is not enough any more when one has to study new laminate materials recommended for weight reduction, to evaluate their suitability to vehicle construction. Among these, apart from high strength steel and aluminum alloys, a huge range of plastics including continuous carbon fiber polymer composites offer the greatest potential for lightweight structures. To surmount various processing and cost hindrances, developments for composite materials are required, obviously based on thorough understanding of their mechanical properties. An article addressing these issues and the testing methods devised, was published at page 21 in the March 2016 issue of Advanced Materials and Processes (AM&P), a publication of ASM International. The article emphasizes that besides static bulk properties of composite materials, like tension, compression, and shear tests, one needs also to characterize properties related to inhomogeneity, such as interlaminar fracture toughness, which measures resistance to delamination. To predict the long-term durability of a material in service, creep and fatigue testing is needed. For studying behavior under crash conditions it is necessary to understand how the material behaves under high rates of strain. Further, tests generally need to be conducted over a range of temperatures and other environmental conditions. Several types of test specimens are mentioned in the article, usually with bonded tabs, to prevent damage in the composite from the squeezing grips jaws. Readers interested in enlarging their understanding in the testing of composite materials are urged to seek the original article indicated above.

Typical composite test specimens.

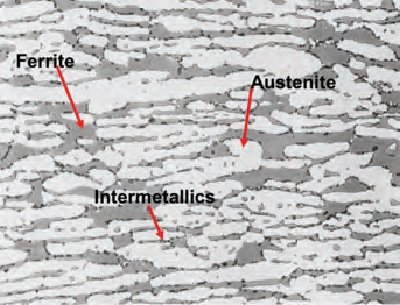

4 - Duplex Stainless Filler Metals and Procedure Qualification Problems The Stainless Q&A column of the Welding Journal for March 2016, written by Damian A. Kotecki, a well known stainless expert worth learning from, discusses the qualification of a procedure for welding duplex stainless steel Alloy 2205, 0.5 in. thick. A manufacturer submitted the query because the results of Test Method C per ASTM A923 exceeded the maximum acceptable. ASTM A923 gives the Standard Test Method for Detecting Detrimental Intermetallic Phase, "to the effect that toughness or corrosion resistance is affected significantly". Kotecki explains that two alloy grades (S31803 and S32205) are given in ASTM A240 for duplex alloy 2205, differing only in the minimum specified content of nitrogen. For welding purposes the second grade with higher minimum nitrogen content is usually preferred because it improves austenite formation in the heat affected zone (HAZ). In the specific case of the query the base material specification was not reported but the author advises that some suppliers provide dual classified materials meeting both requirements. The three methods of ASTM A923 to detect detrimental intermetallic phases are: The standard specifies that both methods B and C are indirect means of determining intermetallic precipitation. The fine print explains that method A is a rapid screening test, whose acceptable results, showing unaffected structure, avoid the need for the Charpy test. The same applies for method C because it can be applied for acceptance but not for rejection, so that the result reported by the inquirer could not influence the qualification. A later follow up showed that method A, the rapid screening, was indeed successful. Readers confronting similar issues are urged to seek the original article quoted above.

(Reprinted with permission from ASTM A923-14, Affected Structure. Structures observed in UNS S31803 as a result of ASTM A923 Test Method A. [From the Welding Journal, March 2016, page 19]

5 - Online Press: recent Welding related Articles Ready, set, interview 6 tips for better GTAW results The $140,000-a-Year Welding Job Welding Productivity: Home Evolution of ageing management An Interactive History of Metallurgy 6 - Terms and Definitions Reminder Adaptive Control pertains to regulator that automatically determines changes in process conditions and directs the equipment to take appropriate action. Backing is a material or device placed against the back side of the joint, adjacent to the weld root to support and shield molten weld metal. In electrogas and electroslag welding, such devices called shoes, usually cooled by running water, are placed at both sides of the joint, with welding proceeding vertically up. Backing material may be partially fused or remain unfused during welding and be either metal or ceramic. Cold welding includes a group of solid state processes in which pressure, exerted by different means, is used to produce a weld without heating and melting, with substantial deformation at the weld. Examples are Ultrasonic welding, Magnetic pulse welding, Explosion welding and Vaporizing Foil Actuator Welding (VFAW). Deposition Rate, relative to a definite process operating at selected parameters with a given filler metal, identified by material and size, is the weight of filler material deposited in a unit of time. Electrode Extension, in welding processes where filler metal is supplied as a continuous wire, is the length of electrode extending beyond the contact tube of the torch and up to the arc. Forge Welding is a solid state welding process that produces a weld by heating the workpieces in a furnace and applying blows sufficient to cause permanent interpenetrating deformation at the faying surfaces. Gas Lens consists in one or more fine mesh screens located at the gas nozzle to produce a stable stream of shielding gas, used in gas tungsten arc welding (GTAW). Horizontal Welding Position is that where the welding axis is approximately horizontal but at least one of the base metal surfaces is in a vertical plane. 7 - Article - A new way to measure Laser Power

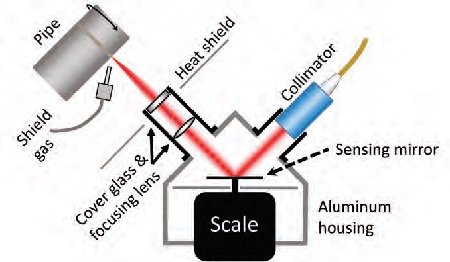

An article published in the March 2016 issue of the Welding Journal at page 30 describes a new way to measure laser power that allows both accurate and real-time measurements of laser welding power, being developed by the National Institute of Standards and Technology (NIST). It explains that, for critical applications where laser welding quality monitoring is required, one needs accurate real time power measurement. Unfortunately however, with current technology one can measure quite accurately the laser’s power but not during the welding process or, while welding, with greatly reduced accuracy. For this development the new NIST approach is different: instead of absorbing all the laser light, it was preferred to reflect it as much as possible from a mirror and, rather than measuring heat, to measure the very small force of the light as it pushes on the mirror. The idea of measuring the radiation pressure is used in other scientific fields. In this case adaptations had to be found for measuring the energy of high power lasers. It was assumed that if the laser power could be measured to within 1–2% accuracy during welding operation, this would allow for quality monitoring and could simplify the setup process for a weld. A prototype Radiation Pressure Meter (RPM) was set up as a research project using a delicate high precision weight scale. Suitable provisions had to be implemented to insulate the scale from all sources of vibration and other disturbance. The scale employed can sense a change in mass as small as 10 µg. A high quality (Distributed Bragg Reflector) mirror that reflects more than 99.9% of the incident laser light was employed so that the power absorbed by the reflecting mirror was assumed to be less than 0.1% of that of the laser beam. Therefore, by recording the light force (radiation pressure), the optical power of a laser beam could be measured. The article describes at length the actual makeup of the prototype instrument and the arguments that influenced the actual choices of the means employed. Then practical laser beam welding (LBW) tests were performed, while recording the measured power employed, and correlating the results with the metallographic examinations of weld sections. The uncertainty of the laser power measurement using the radiation pressure power meter is a preliminary estimate to be refined further with more measurements, but currently the uncertainty is dominated by that in calibration of the scale over the lowest mass ranges (300–500 µg), which correspond to about 600–1000 W of laser power. The uncertainty of the scale calibration at these lowest levels is estimated at about 1.5%. The article explains the advantages of using a "Pick-Off" measurement of a fraction of the laser light beam by using a photodiode (a small, semiconductor-based optical power detector): while the accuracy is low, its response is immediate. Therefore hybrid techniques are being studied where the radiation pressure power meter calibrates the photodiode in real time (eliminating concerns about drift in the pickoff ratio) to provide a fast and accurate measurement. The scientific approach used to test the innovative idea of real time measuring of laser beam power during welding promises that future developments and experience will provide practical, useful means to monitor laser beam welding quality. Readers interested in laser beam applications are urged to read the quoted article, briefly summarized here, recommended for the breadth and the depth of the information provided.

Diagram of radiation pressure power meter (RPM) 8 - Site Updating: Bulletin_117 with Resources on Metals, Part 1 As announced in our page on Metals Knowledge, the first of the series of Mid Month Bulletins was published, dedicated to provide readers with selected links to quality information. It can be found at Bulletin 117. Readers who accept our invitation to build in the memory of their computer a valuable Encyclopedia on what they may ever need to understand and learn important issues affecting Metals and Welding, should start as soon as possible to organize and gather the information. Starting now will prepare the work to be done when the next issues are published. The importance to be able to find reliable information cannot be overemphasized. Building your Encyclopedia will put you in the best position to enjoy the knowledge and making it part of your know how. If you care for the advancement of your professional career you can appreciate the opportunity to reach and learn from most diverse sources to better understand difficult issues. If you think your personal organizing solution may have some merits your colleagues could like, you are welcome to share it with this readership. Readers who actually did the work proposed, are welcome to share their comments on the whole project of Encyclopedia building. 9 - Short Items

9.1 - Mechanical Testing consists of the methods by which the mechanical properties of a metal are determined. 9.2 - Open-die Forging is the hot mechanical forging of metals between flat or shaped dies in which metal flow is not completely restricted. Also known as hand or smith forging. 9.3 - Proof Testing means subjecting a component or system at its peak operating load or pressure or at a predetermined higher value to verify its correct operation. 9.4 - Quality represents different concepts in different contexts: 9.5. - Runner is a channel in the casting mold through which molten metal flows from one receptacle to another. 9.6 - Surfacing Weld is a type of weld composed of one or more stringer or weave beads deposited on an unbroken surface to obtain desired properties or dimensions.

10 - Explorations: beyond the Welder Special Report: The Psychology of Terrorism Rescue Mission: Freeing Young Recruits from the Grip of ISIS Fueling Terror: How Extremists Are Made What You Don't Understand about Suicide Attacks Weakening Encrypted Communications Would Do Little to Stop Terrorist Attacks, Experts Say 11 - Contribution: Minimizing Alpha Case

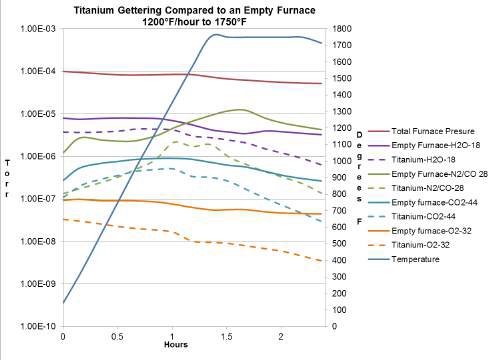

All those who work with titanium alloys for demanding applications, mainly aerospace, know that specifications require to check and to limit the alpha case on the surface. Alpha case is a diffusion reaction occurring at the surface of titanium parts when heating at elevated temperature. Various gases in the furnace atmosphere including vacuum, contribute to form it. Oxygen at low concentrations acts as a solution strengthener, but at higher concentrations decreases ductility and forms alpha case, a brittle constituent that has a detrimental effect on part performance and stability. An article on the subject mentioned in the title is published at page 12 in the periodic HTPro of March 2016 (Volume 4, Issue 1), the official letter of the Heat Treating Society of ASM International. The above leaflet is included as an insert in the March 2016 issue of Advanced Materials and Processes (AM&P), a publication of ASM International. It describes an experimental procedure that was undertaken to check whether the protocols required by applicable specifications like AMS2769, are reliably effective in reducing alpha case formation. The quoted article describes in detail the experimental procedure, specifying different ramp rates that were adopted for various specimens that were sectioned to determine the depth of case. Furthermore the vacuum furnace atmosphere was checked with a Residual Gas Analyzer to provide a trend analysis of relative gas composition and pressure during the cycle. The following results are reported: The study showed that "Varying ramp rates or instituting intermediate temperature holds during outgassing did not minimize the formation of alpha case, owing to the strong gettering effect of titanium as revealed by the RGA." The conclusions are: A side note adds that: Interested readers are urged to read the original article, by downloading it from the following link: Readers with personal experience on the topic are invited to contribute their point of view.

Residual Gas Analyzer (RGA) trends show strong gettering effect of titanium.

12 - Testimonials On Wed Mar 02 14:07:03 2016, the following results

were submitted from the "Form 5" on welding-advisers.com: Name: todd marshall todd

On Sun Mar 13 09:58:10 2016, the following results were submitted from the "Form 5" on welding-advisers.com: Name: Darr Or [...] 13 - Correspondence: a few Comments It is quite some time that I implemented the policy of requesting the payment of a minimal sum in exchange for the time and work required for preparing a suitable answer to readers' questions. Most of the inquirers drop their request with no further communication, rather than paying, confirming to me that the question itself was not worth my working time and attention. As if they could ask their lawyer or their doctor without paying for the advice sought. Exceptionally someone answers with an angry "no" as if it were my obligation to provide an answer at no cost. It is not. What really mattered for me, and what I almost never got, is a word of thanks and a follow up on what happened next, after my answer. No complaints, though, this is how it works. Unfortunately there is almost always a cost for ignorance or incompetence, but it is mostly hidden, and management is not aware of the influence of mistakes on the bottom line, or at least they don't know and don't care. Frequently management itself prefers to cover up failures with costly internal trials that bring nowhere, instead of engaging the services of an expert that would save time and money. 14 - Bulletin Board 14.1 - 9th International Seminar & Conference on Advances in Resistance Welding

14.2- International Conference on Plastic Welding and Joining We Were Just Trying to Make Ends Meet

Watch - The Video:

and also

BUILT BY: Click on this Logo NOW! No better way to get to know SiteSell, Specific questions about SiteSell?

Copyright (©) 2016, by Elia E. Levi and

See you next time... |

|||||||||||||

| Back to Back Issues Page |