| Back to Back Issues Page | ||||||||||||||

|

||||||||||||||

|

PWL#155, ICTP, Aluminum feedability, SMO 254, FAST, Modern High Temperature Testing, Cast Iron July 01, 2016 |

||||||||||||||

| We hope you will find this Letter interesting and useful. Let us know what you think of it.

PWL#155

PWL#155, Induction Coupled Thermomagnetic Processing, Feedability of Aluminum Filler Metal in GMAW, Welding Austenitic SMO 254 Stainless Steel in a desalination project, Field Assisted Sintering, Modern High Temperature Testing, Resources on Cast Iron, Metals Part 4, for building an Encyclopedia Online, and much more...

July 2016 - Practical Welding Letter - Issue No.155

Important Notice Check the New Mid June Bulletin including Resources on Metals, Part 4.

DON'T USE REPLY to send your messages! Use the Contact Us form instead. This publication brings to the readers practical answers to welding problems in an informal setting designed to be helpful and informative. You are urged to pass-along this publication to your friends, if you like it, and if you think they may enjoy it. The addresses reported hereafter were live and correct at the time of their publication. Note: References to articles or other documents are given here in one of two forms. If they are URL's (Uniform Resource Locator), which is the analogue of an address, they begin with "http://..." or "www.". If the information is important to you as we hope, you may save the selected pages in a suitable folder on your Computer for easy reference.

1 - Introduction 2 - Article - Induction Coupled Thermomagnetic Processing 3 - How to do it well: Feedability of Aluminum Filler Metal in GMAW 4 - Filler Metal: Welding Austenitic SMO 254 Stainless Steel 5 - Online Press: recent Welding related Articles 6 - Terms and Definitions Reminder 7 - Article: Field Assisted Sintering 8 - Site Updating: Bulletin_120, Resources on Cast Iron 9 - Short Items 10 - Explorations: beyond the Welder 11 - Contributions: Modern High Temperature Testing 12 - Testimonials 13 - Correspondence: a few Comments 14 - Bulletin Board

2 - Article - Induction Coupled Thermomagnetic Processing

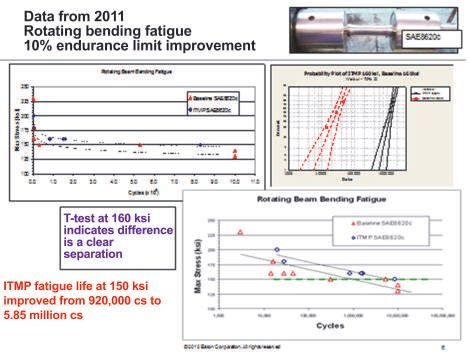

Described as a disruptive technology, the process outlined in the title above promises to improve significantly the mechanical properties of simple steels enabling them to achieve results currently obtained only with complex alloys and costly treatments. The article introduces studies performed by an alliance of companies with ORNL (Oak Ridge National Laboratory). It is published at page 9 in the current issue of HTPro for June 2016, the official letter of the Heat Treating Society of ASM International, and included in the June 2016 issue of Advanced Materials and Processes, a magazine of ASM International. The project called Induction Coupled Thermomagnetic Processing (ITMP) was initiated by the U.S. Department of Energy (DoE), with the purpose to achieve energy savings with a corresponding reduction in the carbon footprint. The article explains that performing controlled-frequency induction heat treatment to metals while applying a strong magnetic field, results in properties not achievable using conventional techniques. The magnetic field produces a change in thermodynamics that alters conventional phase diagrams, providing opportunities to develop alloys with new microstructures and improved physical and mechanical properties. In addition, the acceleration of phase transformation kinetics results in improved processing efficiency and refined microstructural features. In short the high magnetic field assisted processing enables the development of metals with improved performance using faster processing times and less energy. The reported benefits of ITMP, as affecting the iron-carbon diagram, are summarized as follows: • Accelerated transformation kinetics The article concludes the research with the following comments:

Interested readers are urged to seek the original article,

that can be downloaded from the following link:

Improvement in rotating bending fatigue life of ITMP samples over baseline properties

3 - How to do it well: Feedability of Aluminum Filler Metal

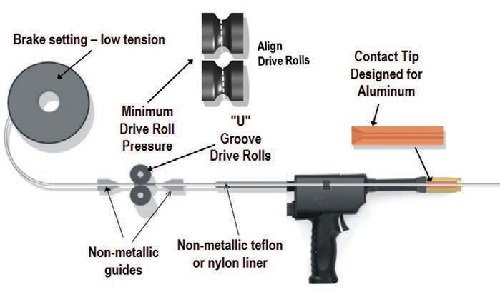

An article with the above title, written by the world renowned expert Tony Anderson, was published in the June 2016 issue of the Welding Journal at page 22, in the Section dedicated to Aluminum Q&A. The author explains that problems are likely to appear especially with softer aluminum alloys like 1100 and 4043 and with smaller diameter wires. The article draws readers' attention to the important differences between gas metal arc welding (GMAW) systems designed for steels and those made especially for work with aluminum alloys. Take care to the Spool Brake settings that are to be adjusted to an absolute minimum just to prevent freewheeling when stopping welding. Higher than minimum pressure will increase the potential for feeding problems and burnbacks. Special automatic braking systems were developed to provide more sensitivity in this area, and are particularly useful to improve feeding. Then a major difference is outlined between systems designed for aluminum vs. those intended for steel: the latter use metallic liners and wire guides, that tend to cause abrasion and wear in delicate aluminum wires. For aluminum applications those parts should be made of soft plastic materials, exactly for preventing those damages. Also drive rolls should be special for aluminum use, smooth, aligned and set to the correct drive roll pressure, again to avoid shavings than can block the liners. Only special contact tips made specifically for aluminum wire welding should be used, with bore diameter 10 to 15% larger than the electrode. Quality and uniformity, surface smoothness, wire diameter control and final treatment of the aluminum filler metal wire should be reliable and consistent, to minimize feedability problems. The type of feeding system used should be suitable to each application, taking into account several parameters, like the type of welding (light or heavy duty), size and alloy, and the need for a long, flexible conduct: in short, no single type meets all requirements. The author's recommendation is: choose the feeding system best suited to your application and set it up to optimize its feeding capability. As single action (push or pull) systems have limited flexibility, specially developed push-pull feeders use the most positive method of feeding aluminum welding wire, essential for robotic or automated operations. GMAW systems dedicated to welding aluminum are to be preferred to convertible ones, also capable to weld steel. It is highly recommended that interested readers and welders who experience difficulties with the issue of Feedability of Aluminum Filler Metal, seek the original article above, that ends by summarizing all the important items explained there in detail, to learn what to do when specific hindrances show up.

Considerations for improved aluminum feedability

4 - Filler Metal: Welding Austenitic SMO 254 Stainless Steel

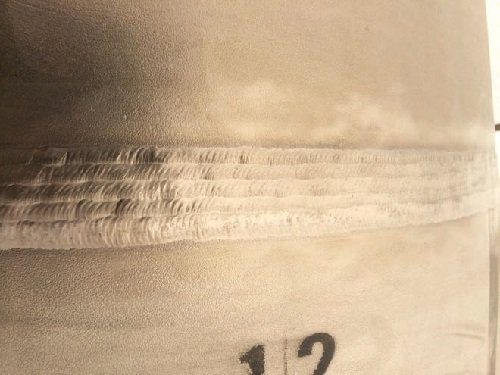

An article published at page 60 in the June 2016 issue of Welding Journal describes the technical details of the construction of a major water desalination plant recently built in California. Of interest are the materials selection and the strict rules enforced during fabrication to ensure soundness and reliability for long years to come. The choice of base material was SMO 254 (UNS 31254), for its ability to provide excellent resistance to crevice corrosion (PREN>40) and pitting, for its high impact toughness, resistance to chloride stress corrosion cracking, and excellent workability and weldability. Like other fully austenitic stainless steels, this one too can be prone to hot cracking in the weld metal. Therefore precise instructions were provided in the working documents (WPS) to limit heat input: to avoid failure risks, constant temperature monitoring and speed control were undertaken. Welding technique involving stringer bead on the weld per pipe manufacturer's recommendation was performed, because weaving can cause excessive heat input, and for the same reason maximum interpass temperature was specified. Gas purging was specified and gas backing was used. The root pass was made by GTAW process with EW-Th-2 thoriated tungsten electrode with DC straight Polarity, using Avesta P12 Polarit (1.6–3.2 mm diameter) ER NiCrMo-3 as the filler metal. Filler metal wire for GMA Welding is not specified in the article but it is believed it should comply with AWS Specification A5.14 (AWS electrode classification ERNiCrMo-3) and ASME Specification SA5.14. A well conceived program was put in place with the concurrence of the local labor union, to train the workforce for the special requirements of the project, as welder qualification was essential to the project success. Special provisions were devised to monitor and record important parameters and then to calculate travel speed and heat input in order to check that limits were not violated. Furthermore all the welds on the SMO 254 piping were 100% radiographic inspected. In conclusion the article stresses that a special effort was invested to understand the weldability and essential variables in alloy SMO 245, with the purpose to make sure that the plant withstands the corrosive attacks of seawater and the high pressures developed in the Reverse Osmosis process. Interested readers are urged to seek the original article to see what is involved in realizing a successful complex welding project.

A completed weld on the SMO 254 alloy pipe at the Carlsbad Desalination Plant.

5 - Online Press: recent Welding related Articles New Screws Cut Weight When Joining Parts

and Sheets of Metals GM says it’s first to weld steel to aluminum Growing Demand from Wind Energy Sector to Create Opportunities for the Lincoln Electric Releases Revised Aluminum GMAW Welding Guide Pipe Production Automation (Navy Video)

6 - Terms and Definitions Reminder Lamellar tear is a subsurface terrace and step-like crack in rolled, laminated base metal with orientation parallel to the wrought surface, caused by tensile stresses in the through thickness direction of the base metals, weakened by the presence of small, dispersed, planar shaped nonmetallic inclusions, parallel to the metal surface. Malleable Cast Iron is an iron-carbon alloy which combines the outstanding properties of cast iron and steel to produce a material which can still be cast, allowing the production of complex shapes combined with a thin wall section but has improved strength and ductility. In its cast state it is very hard and brittle and unsuitable for most engineering applications. A controlled heat treatment process (annealing), applied to the cast material, changes the structure and reduces the carbon content. The resulting microstructure gives a less hard material, no longer brittle and with good malleable and ductile properties while retaining a sufficiently high strength. Nontransferred arc is one established between the electrode and the constricting nozzle of the plasma arc torch or thermal spray gun. The workpiece is excluded from the electric circuit. Oxidation is (1) a reaction in which there is an increase in valence resulting from a loss of electrons. Plug weld is made in a circular hole in one member of a joint, fusing that part to another member. Reinforcement (face or root) is weld addition, i.e. excess material deposited over the level of adjoining base metal members, to assure that minimum weld dimensions are achieved. Salt bath dip brazing is a variation of dip brazing process where assemblies to be brazed are immersed into a molten salt bath furnace. Tack Welds are made to hold parts of a weldment in proper alignment until the final welds are completed.

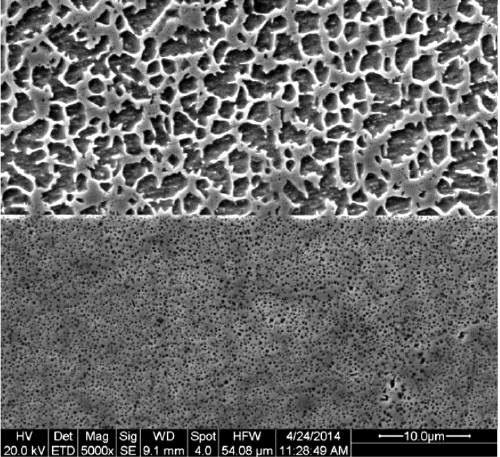

7 - Article: Field Assisted Sintering

An article published at page 22 in the June 2016 issue of Advanced Materials and Processes (AM&P), a magazine of ASM International, sheds new light on important improvements brought about by perfecting advanced technologies. In this case, the goal in the manufacture of modern aeroengine gas turbines, is doubling the thrust-to-weight ratio of the engine, which is achievable by reducing the weight of turbine components and increasing the speed of rotating parts. The article reminds that Linear friction welding (LFW) (see PWL#150 (7)) is used to join blades to disks to manufacture polycrystalline titanium compressor blisks, where the materials are easily deformed. Unfortunately, for the turbine, where the blades are cast nickel base single crystal alloys, and the disks are forged, LFW is not practical. NASA developed low-density, single-crystal (LDS) nickel-base superalloys for turbine blade applications, which offer significant improvements in the thrust-to-weight ratio. To take advantage of potential weight savings, researchers looked at joining LDS Ni-base superalloys via FAST (field assisted sintering technology). Nickel-base superalloys for advanced disk applications require high creep resistance and crack growth resistance in the rim region to withstand temperatures exceeding 650°C, and high strength and fatigue resistance in the bore and web regions, which operate at temperatures of 500°C or less. A uniform grain structure along the disk radius cannot accommodate the different temperature dependent stress conditions. Therefore, an optimal disk should have a dual microstructure, consisting of fine grains in the bore and web and coarse grains in the rim. Low-solvus, high-refractory (LSHR) Ni-base superalloy turbine disks were processed using a dual microstructure heat treatment producing a microstructural gradient consisting of coarse grains in the rim and fine grains in the bore. The article shows micrographs of a good bond between LDS and LSHR Ni-base superalloys using FAST at a temperature of 900°C. To provide turbine disks with the required properties in all regions, Hybrid Disks are being developed, either by solid state joining of two different materials with a sharp interface, or by using two different powder materials compacted and sintered together forming a hybrid disk without a sharp interface. According to the article, mechanical properties of the interfaces are now being evaluated. Other lines of development for other products are being pursued in the same research center. Readers interested in following more closely these and similar developments are urged to seek the original article where they can find also how to contact the author.

Scanning Electron Micrograph of LDS Ni-base superalloy

to LSHR Ni-base superalloy

8 - Site Updating: Bulletin_120, Resources on Cast Iron The Page of this Month introduces more information on Resources on Metals, Part 4 aimed to enrich your Materials Encyclopedia built from articles gathered online. This page is dedicated to Cast Iron. Due to the various types of Cast Irons available, their different properties and applications, it is most important for informed professionals to have an updated database where information is right on their fingertips. It is therefore recommended to busy readers to dedicate the required time to perform gathering and organizing in a practical way the pages available from many sources. Also brochures and catalogs from commercial companies may provide useful information, despite the built in bias they may provide for advertising purposes. To download all the pages introduced in Resources on Metals, Part 4, dedicated to Cast Irons, Metallurgy, properties, applications and welding procedures click on Bulletin 120. Then organize the downloaded material in indexed folders, arranged for easy retrieval of information.

9 - Short Items

9.1 - Local Action is the Corrosion due to the action of "local cells," that is, galvanic cells resulting from inhomogeneities between adjacent areas on a metal surface exposed to an electrolyte. 9.2 - Macroshrinkage means isolated, clustered, or interconnected voids in a casting, that are detectable macroscopically. Such voids are usually associated with abrupt changes in section size and are caused by feeding that is insufficient to compensate for solidification shrinkage. 9.3 - Normal Segregation is the Concentration of alloying constituents that have low melting points in those portions of a casting that solidify last. 9.4 - Oxygen Probe is an atmosphere-monitoring device that electronically measures the difference between the partial pressure of oxygen in a furnace (or furnace supply atmosphere) and the external air. 9.5 - Passive is (1) a metal corroding under the control of a surface reaction product or (2) the state of the metal surface characterized by low corrosion rates in a potential region that is strongly oxidizing for the metal. 9.6 - Radial Marks are Lines on a fracture surface that radiate from the fracture origin and are visible to the unaided eye or at low magnification. Radial marks result from the intersection and connection of brittle fractures propagating at different levels. Also known as shear ledges.

10 - Explorations: beyond the Welder Excitement Builds for the Possibility of Life on Enceladus IEA Warns Air Pollution to Kill Millions More If Policies Don't Change The "Internet of Things" Needs a Fix 2-Dimensional Materials Create New Tools for Technologists A Huge, Floating Screen Will Sift Plastic out of the Ocean

11 - Contributions: Modern High Temperature Testing

A comprehensive article, published at page 17 in the June 2016 issue of Advanced Materials and Processes (AM&P), a magazine of ASM International, illustrates the needs of advanced industries, and the corresponding achievements of testing equipment suppliers, aimed at measuring accurately and precisely material properties at elevated temperatures. The author reminds to the reader that high heat may mean at least three different temperature ranges to three groups of researchers. The first range, 200°-425°C, applies to polymer matrix composites (PMCs). Test engineers need to carefully consider tradeoffs in each range, in order to run effective tests, measure material properties at elevated temperatures, and acquire high-quality results. Accuracy and precision of mechanical test data are directly affected by these tradeoffs, because any object that holds, touches, or is placed near the specimen may increase data scatter. All the essential tools and accessories involved in such testing are thus potential sources of experimental error. Special attention must be devoted to the development of suitable grips for PMC to avoid damage to the reinforcing fibers in the matrix. Hydraulic grips help maintain the correct pressure as the chamber and grip wedge heads heat up, but they become relatively large, commanding adequately large environmental chambers. That makes difficult using contact extensometers, therefore requiring non contact devices that complicate the issue. Testing at the highest temperatures challenges the strength of the grips, requiring special solutions, like selective cooling, for testing the most heat resistant materials. The article concludes that very few commercial off-the-shelf solutions exist for high-temperature materials testing. But making ad hoc solution for specific problems introduces new challenges, like systems integration expertise requirements. These are needed for innovative high-temperature testing to reduce data variability and to allow researchers to run fewer tests in order to achieve accurate results. Interested readers are urged to seek the original article to learn the issues in depth and possibly to discuss their problem with the expert author.

Remotely actuated hydraulic grips for

PMC specimen at

temperatures to 425°C

12 - Testimonials On Sat Jun 04 02:50:45 2016, the following results were submitted from the "Form 5" on welding-advisers.com: Name: Sayeed Parvez

13 - Correspondence: a few Comments Our tireless revisor Mr. Anthony Rangus, to whom I am obliged for many pertinent observations, took issue with a definition published in the last issue of this publication. He writes: "The following is stated: "Acceptable Weld is the one that meets all applicable requirements." I admit that Mr. Rangus might be right, and he could certainly forward his remark to the AWS Committee for Terms and Definitions who could profit from his input.

14 - Bulletin Board 14.1 - 3rd Welding Education, Skills & Certification Conference 14.2 - Lasers Conference.

See you next time...

Watch - The Video:

and also

BUILT BY: Click on this Logo NOW! No better way to get to know SiteSell, Specific questions about SiteSell?

Copyright (©) 2016, by Elia E. Levi and

Back to Past Issues of PWL.

|

||||||||||||||

| Back to Back Issues Page |