| Back to Back Issues Page | |||||||||

|

|||||||||

|

PWL#158, Advances in High Entropy Alloys, Spatter Reduction, Ferrite Content, Cross-Arc Welding October 05, 2016 |

|||||||||

| We hope you will find this Letter interesting and useful. Let us know what you think of it.

PWL#158

PWL#158, Advances in High Entropy Alloys, Spatter Reduction, Comparing measured and calculated Ferrite content, Research on Cross-arc Welding, Composite Dies, Issues that will disrupt the industry, Comments and much more...

October 2016 - Practical Welding Letter - Issue No.158

DON'T USE REPLY to send your messages! Use the Contact Us form

instead. This publication brings to the readers practical answers to welding problems in an informal setting designed to be helpful and informative. You are urged to pass-along this publication to your friends, if you like it, and if you think they may enjoy it. The addresses reported hereafter were live and correct at the time of their

publication. Note: References to articles or other documents are given here in one of two forms. If they are URL's (Uniform Resource Locator), which is the analogue of an address, they begin with "http://..." or "www.". If the information is important to you as we hope, you may save the selected pages in a suitable folder on your Computer for easy

reference.

1 - Introduction 2 - Article - Advances in High Entropy Alloys 3 - How to do it well: Spatter Reduction 4 - Filler Metal: Comparing measured and calculated Ferrite content 5 - Online Press: recent Welding Related Articles 6 - Terms and Definitions Reminder 7 - Article: Cross-Arc Welding 8 - Site Updating: Composite Dies 9 - Short Items 10 - Explorations: beyond the Welder 11 - Contributions: Issues that will disrupt the industry 12 - Testimonials 13 - Correspondence: a few Comments 14 - Bulletin Board

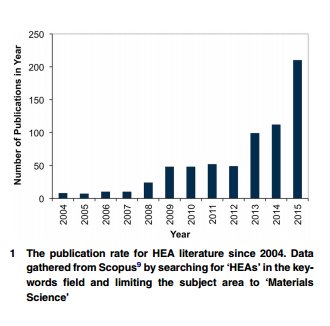

2 - Article - Advances in High Entropy Alloys This subject was introduced in PWL#140 - April 2015, more than a year and a half ago, as the big promise of metallurgical innovation, likely to introduce soon new materials exhibiting exceptional mechanical properties capable of unheard of performance in all kinds of demanding applications. Now however, while much research work has be done and better understanding has been achieved, we are still awaiting the appearance of those materials whose promise is still looming some time in the future. The article summarized hereafter, providing a critical review of research work performed over recent years, still affirms that "Their use as structural materials is one of the most promising and exciting opportunities", referring to new High Entropy Alloys. The introduction reminds that those are compositionally very different from classical engineering alloys, as they contain multiple principal alloying elements in near equi-atomic ratios. From the first original discovery work and subsequent research on fundamental properties, four main characteristics, called core effects, were singled out and proposed:

By assessing these claims on the basis of existing experimental evidence in the literature, as well as classical metallurgical understanding, the article challenges the validity of the above assumptions and concludes that the significance of these effects may not be as great as initially believed. The critical assessment of the first of the core effects above reveals that in many of the alloys studied the phase stability is much weaker than originally believed. In fact, excluding a few very specific compositions, the majority of the other HEAs investigated have been found to decompose into more than one solid phase given the correct heat treatment. The article therefore concludes that there is limited evidence to suggest that entropic stabilization has an overarching effect on the microstructural stability of HEAs. "In the rare cases that HEAs have been found to be stable as a single solid- solution phase, it is not the effect of high configurational entropy that leads to their stability. Rather, it seems that the enthalpy term associated with solution separation or intermetallic formation has not been significant in these cases. The influence of enthalpy, not entropy, is predominant". At this point the article embarks in a discussion about the naming of these alloys as a group, recommending further work to establish a systematic convention for calling different HEAs classes by specific attributes. Concerning the second point, on severely distorted lattices, the article reminds that the introduction of substitutional solute atoms into a solvent matrix causes the displacement of neighboring atoms from their ideal lattice positions, generating a strain field whose interactions with dislocation movement result in solid-solution strengthening. However in certain studies it appears that the strengthening effect of precipitates may have been overlooked. The article concludes that this topic requires further investigation. On the third core effect, namely sluggish diffusion kinetics, the article observes that there is a great deal of experimental evidence that implies that atomic movement in HEAs is not unusually sluggish, as confirmed by observations of precipitation in many as-cast HEA samples, including those subjected to very rapid cooling, and it concludes that "in summary, the evidence considered here suggests that atomic diffusion in HEAs is unlikely to be anomalously slow, and that it is certainly not so in a generalized sense across all HEAs". Finally the article dismisses the last core effect, as rules of mixtures, permitting to explain special properties, applies also to conventional alloys. The article advocates a search to the route for alloy development for structural applications, because of the enormous range of possible HEA alloy compositions, and provides several examples where phase prediction was based on parametric studies, but it advises that there are some significant limitations. The concluding remarks include the following understanding: "HEAs have thrust us out of an age of limitation, where alloys were designed around one principal element, and into a new world of seemingly endless possibility. However, careful and educated alloying is required, such that we focus our attention on key features of the compositional landscape presented by HEAs, rather than wander somewhat aimlessly in its limitless expanse." Readers interested in the subject of HEAs and their development are advised to download and study the article High-entropy alloys: a critical assessment of their founding principles and future prospects (20 pages)

Publication Rate for HEA from 2004 [From the quoted article above, page 3]

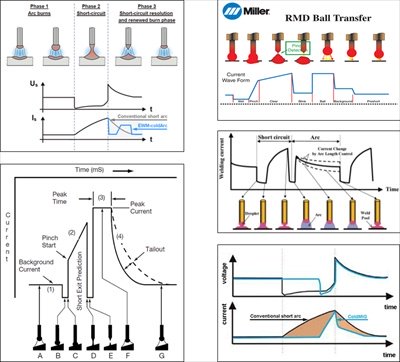

3 - How to do it well: Spatter Reduction A comprehensive article by TWI throws light on the means that different equipment suppliers developed in recent times to control and reduce spatter generation. The article is titled: The article analyzes the different forms of metal transfer and provides graphs indicating the change of voltage and current during the various phases of material detachment from the electrode. It goes on explaining the need of finer control in order to improve the quality of the weld and the efficiency of the process. Different solutions are proposed by different manufacturers, all intending to improve control and stability of current profile, aiming at reducing spatter generation and enhancing heat input control. No indication is given as to which solution is to be preferred in which circumstances. This leaves users with an overchoice, very much dependent on the persuasion arts of equipment sale agents. Only by using in practice different systems and comparing their performances in applications typical to the shop, can one establish preferences with some confidence of having done the best selection for the jobs at hand. Interested reader are urged to see the original article indicated above, and to prepare the critical questions they should ask suppliers to meet their purposes and solve their problems.

Waveforms produced from different Power Sources. Clockwise from top-left: EWM ColdArc, Miller RMD, Daihen CBT, Merkle ColdMIG and Lincoln STT. [From the TWI Article above, Fig.3]

4 - Filler Metal - Comparing measured and calculated Ferrite content

Measured ferrite content in austenitic stainless steel GMA weld metal from metal cored electrode EC308L was found much higher than the calculated ferrite content. The same was not found when using solid metal electrode ER308L. Answering to the question on the reasons for the difference, our preferred mentor Damian J. Kotecki writes at page 50 in the September 2016 issue of the Welding Journal that measurements made with a calibrated instrument should take precedence over predictions, however diligently calculated. The Author advises that there is a fundamental difference in the Nitrogen content in the two types of filler metal: while in the solid rod N is assumed as 0.08%, in the metal cored wire it is more likely 0.02%. The difference stems from the different processing of the solid wire, from stainless material, vs. the metal core one, where all the alloying elements are present in the filling. Just by taking nominally identical materials, having different nitrogen contents as assumed above, brings about the different calculated contents as appearing in the reported diagram, and as reported by the inquirer. Better results could have been obtained by using actual nitrogen content. As usually, the article summarized above is highly instructive. It is strongly recommended to all readers needing Ferrite Number measured or predicted.

5 - Online Press: recent Welding related Articles GE makes $1.4B bet on 3D printing, acquires two firms to boost additive manufacturing Exploration and Development of High Entropy Alloys for Structural Applications 'Significant changes' announced for Honda, Acura

welding, sectioning rules 5 Ways To Keep Your Cool Huntingdon Fusion Techniques monitors argon quality during welding processes 6 - Terms and Definitions Reminder Overwelding is welding made in excess of what is required for sustaining the applied stresses. It results from inaccurate cutting and fitting, poor supervision, insufficient training or lack of confidence in the strength of the weld as specified. It results in unforeseen, useless costs. Projection Welding is a resistance welding process where the heat is produced by resistance to the flow of electric current between two electrodes pressing on the elements to be welded. The resulting weld nuggets are localized at predetermined points by projections, embossments or intersections. Runoff Weld Tab is an additional plate, placed beyond the end of the joint, on which the weld is terminated. Stringer Bead is a weld bead deposited along a straight line travel without weaving. Transferred Arc is an electric arc struck between the electrode of the torch and the workpiece. Underfill is a groove weld condition in which the weld face or root face is below the adjacent surface of the base metal. V-groove weld is a type of groove weld performed on base metal where a V-groove was machined. Wormhole porosity is a nonstandard term when used for piping porosity, which is a form of porosity with length greater than its width that lies approximately perpendicular to the weld face.

7 - Article: Cross-Arc Welding

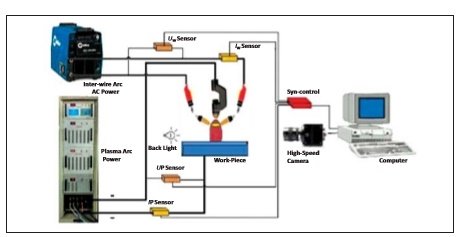

A research article published at page 340-s in the Welding Research supplement of the September 2016 Issue of the Welding Journal starts with the observation that regular Gas Metal Arc Welding (GMAW), the most widely used welding process, has an inherent weak point. It consists in the fact that when one wants to increase deposition rate, one increases also the heat input. In the search for higher productivity this is seldom desirable. The researchers tried to build a new welding process that would decouple the effects by separating the molten filler metal supply from the arc employed to heat the workpiece. By using an indirect arc between two filler metals in close position fed by an alternating current power supply, while the workpiece is not connected to the power source, heat input is minimized but is also non controllable. The article makes reference to a similar process using also a GTAW electrode to form a bypass arc, melting a wire supplied independently from that of the GMAW, providing improvements in quality and productivity. In the present study, the GTAW process that was previously used was substituted by a plasma arc (PAW), while a cross-arc is established between two GMAW wires made to advance one toward the other with separate speed control, and the heat input into the workpiece is controlled by the Plasma Arc. The Plasma arc force is essential to detach the droplets from the wires. The larger the pulse duration and the larger the plasma gas flow the greater the force on the droplets and the smoother the metal transfer. While this new method seems still far from being easily introduced in the typical welding shop, the process may be worth of attentive follow-up especially for the cases where productivity improvement is needed without unduly increasing heat input in the workpiece. Interested reader are urged to seek this article, titled

Experimental System for Cross-Arc Welding Process [From the Article above, Welding Journal September 2016, Fig.6, page 341-s]

8 - Site Updating: Composite Dies The pages of this Month are a surprise, in that they don't deal with subjects related to welding, the main theme of this website. For a number of reasons the author, after coming up with new ideas relative to methods for building forging or forming dies, decided to publish them in this place to make them available to a larger public. It is expected that our readers are not so narrow minded to refuse to look at something outside of the principal interests of this publication. In this case you may enjoy reading what is all about in a page on Two other pages can be reached, one describing methods of assembling such dies, at the other showing the

calculations to be made to assure stability, at Comments and feedback on these pages are welcome. Please use the Contact Us Form.

9 - Short Items

9.1 - Mill Scale is the heavy oxide layer that forms during the hot fabrication or heat treatment of metals. 9.2 - Necking is the reduction of the cross-sectional area of a material in a localized area by uniaxial tension or by stretching. Also the reduction of the diameter of a portion of the length of a cylindrical shell or tube. 9.3 - Overdraft is a condition wherein a metal curves upward on leaving the rolls because of the higher speed of the lower roll. 9.4 - Passivity is a condition in which a piece of metal, because of an impervious covering of oxide or other compound, has a potential much more positive than that of the metal in the active state. 9.5 - Ratcheting is the progressive cyclic inelastic deformation (growth, for example) that occurs when a component or structure is subjected to a cyclic secondary stress superimposed on a sustained primary stress. The process is called thermal ratcheting when cyclic strain is induced by cyclic changes in temperature, and isothermal ratcheting when cyclic strain is mechanical in origin (even though accompanied by cyclic changes in temperature). 9.6 - Sand is a granular material naturally or artificially produced by the disintegration or crushing of rocks or mineral deposits. In casting, the term denotes an aggregate, with an individual particle (grain) size of 0.06 to 2 mm (0.002 to 0.08 in.) in diameter, that is largely free of finer constituents, such as silt and clay, which are often present in natural sand deposits. The most commonly used foundry sand is silica; however, zircon, olivine, aluminum silicates, and other crushed ceramics are used for special applications.

10 - Explorations: beyond the Welder Why the Deadly Louisiana Flood Occurred Can a Supercomputer Suggest the Best Cancer Treatment? Love in the Age of Machine Learning New Membrane Could Save $2 Billion a Year for U.S. Industries Why Your Children's Commute Won't Look Anything Like Yours

11 - Contributions: Issues that will disrupt the industry The Fabricator's new issue runs an article that asks some tough questions. But instead of discussing the problems and suggesting how to analyze them, after listing them, it refers the readers to a specialized firm whose job is to help industries grow. Nevertheless people active in their fields may realize that massive change is bound to occur, and that the best chances to survive and succeed are to adapt to the changes, as Darwin explained a long time ago. As problems become too hard to solve them alone, it may be a good idea to look for help, either by joining forces with alike people or by studying with external advice how to restructure activities. In the most difficult cases the last resort may be to find out how to quit before it is too late. The article indicated hereafter has a link sending to a program highlighting some of the issues in general terms. The consulting firm quoted, or other ones, capable of helping industry reorganize, may indeed suggest the general framework into which one should move. But it is essential that the hard choices on selection of items to be produced by which machines and methods will be made by those most adapted to take decisions and introduce innovations in their own activity. Readers facing these and similar difficulties are invited to share how they plan to confront them. Manufacturing Leadership Council names six issues that will disrupt the industry

12 - Testimonials From Michael, PRACTICAL WELDING LETTER Unsubscribed There is nothing you or your publication did or didn't do that lead to this [unsubscription]. I am just cleaning up what arrives in my inbox at work. I had gotten advice from you a number of years back when I needed, and I am grateful. I have been out of the welding "field" for a few years now, so unfortunately this is just one of the type of e-mails that no longer gets looked at or read. If I ever do get back in the field, I know of your existence and knowledge base. Therefore, I would not hesitate to re-subscribe and/or directly ask questions. I will also continue to refer you to weldors I know (new or experienced) that may have questions. Sincerely, 13 - Correspondence: a few Comments The fact that students ask immature questions is not surprising. They still don't know what they need. But it often appears that they did not make any effort to understand their problem. In that case I simply refer them to browsing our website, asking them to come back with clearer queries. But it is quite amazing that inquirers already deeply involved with welding ask their question after the fact. As an example, a recent query was related to an

order of welded items from abroad. It should have been obvious that any quality requirements should have been spelled out at the time of ordering. 14 - Bulletin Board 14.1 - 10th International Conference on Trends in Welding Research 14.2 - 28th National Robot Safety Conference 2016. 14.4 - ASNT Annual Conference 2016. 14.5 - So you are the new welding engineer

See you next time...

Watch - The Video:

and also

BUILT BY: Click on this Logo NOW! No better way to get to know SiteSell, Specific questions about

SiteSell?

Copyright (©) 2016, by Elia E. Levi and

Back to Past Issues of PWL.

|

|||||||||

| Back to Back Issues Page |