| Back to Back Issues Page | ||||||||||||||

|

||||||||||||||

|

PWL#161, Adv. Microwave Brazing, Computer Modeling,Ni-WC Hardfacing, Inadequate Welding Screens January 01, 2017 |

||||||||||||||

| We hope you will find this Letter interesting and useful. Let us know what you think of it.

PWL#161

PWL#161, Advanced Microwave Brazing, Computer Modeling for Induction Hardening, GMAW Ni-WC Hardfacing on steel, American Welding Society steers its Global Strategy preparing for a Future of Global Engagement, Beware of Inadequate Welding Screens, Plasma Arc Gouging and much more...

January 2017 - Practical Welding Letter - Issue No.161

DON'T USE

REPLY to send your messages! Use the Contact Us form instead. This publication brings to the readers practical answers to welding problems in an informal setting designed to be helpful and informative. You are urged to pass-along this publication to your friends, if you like it, and if you think they may enjoy it. The addresses reported hereafter were live and correct at the time of their publication. Note: References to articles or other documents are given here in one of two forms. If they are URL's (Uniform Resource Locator), which is the analogue of an address, they begin with "http://..." or "www.". If the

information is important to you as we hope, you may save the selected pages in a suitable folder on your Computer for easy reference.

1 - Introduction 2 - Article - Advanced Microwave Brazing 3 - How to do it well: Computer Modeling for Induction Hardening 4 - Filler Metal for Ni-WC Hardfacing 5 - Online Press: recent Welding related Articles 6 - Terms and Definitions Reminder 7 - Article: AWS Roadmap on Global Engagement 8 - Site Updating: Plasma Gouging 9 - Short Items 10 - Explorations: beyond the Welder 11 - Contributions: Beware of Inadequate Welding Screens 12 - Testimonials 13 - Correspondence: a few Comments 14 - Bulletin Board

2 - Article - Advanced Microwave Brazing

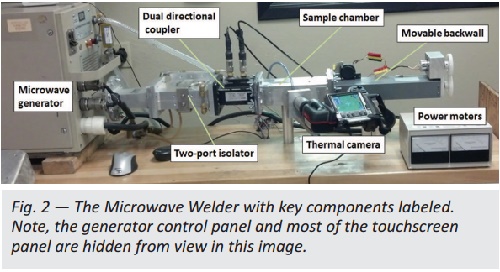

The information on a new Advanced Microwave Brazing process is published in the December 2016 issue of the Welding Journal at page 15. The system, capable of joining difficult-to-weld dissimilar combinations of advanced metals to ceramics and/or polymers, was recently patented by researchers affiliated with LeTourneau University, Longview, Texas. It is enhanced by use of predictive simulation software. The plasma-less closed-loop controlled system, to be built as scaled up prototypes, is expected to be developed to join advanced ceramic-matrix composites for elevated temperature and wear applications in the aerospace, oil and gas, and electronics industries. The extreme reproducibility and reliability of this closed loop controlled noncontact heating method makes the process interesting for Research and Development partners seeking solutions for critical applications. For more information interested readers are referred to the Article:

[From the Welding Journal Research Supplement, April 2016, page s-142]

3 - How to do it well: Computer Modeling for Induction Hardening

The article published at page 12 of the recent November/December 2016 issue of HTPro Vol 4 Issue 4 reminds that determining the appropriate inductor profile might be cumbersome and time-consuming. Required heat source control can be achieved by adjusting the current-carrying face of the appropriate inductor section, applying flux concentrators, and by varying the inductor-to-workpiece gap. In particular, in single shot inductors, made for rotating parts to be heat treated, the entire region to be hardened is heated at the same time. Single-shot inductors typically control hardness pattern and distortion better than scan and static hardening, particularly for stepped shafts. Computer simulation enables prediction of how different interrelated and nonlinear factors could impact the transitional and final thermal conditions of the heated component. It also helps determine what must be accomplished to improve process effectiveness to establish the most appropriate process recipes. Computer modeling helps when designing new inductors used for surface hardening of complex shape items, avoids unpleasant surprises, shortens the learning curve, and reduces development time by removing guessing. The article observes that most existing software programs are not capable of modeling single shot hardening. However, Finite Elements Analysis software developed by specialists working in the industry, enables taking into consideration all critical features of the induction hardening process. The article explains in detail the case study of a specific development process. Accurate descriptions of phase transformations and mechanical properties of individual phases are required for thermal stress analysis. The information contained in phase transformation diagrams and in dilatometry strain curve during martensite formation under continuous cooling is necessary to determine conditions developing in the parts during the processing time. Residual stresses are mapped in the final diagrams, helping to determine treated parts performance. This particular publication, Vol 4 Issue 4 of HtPro is included as an attachment to the November/December 2016 issue of Advanced Materials and Processes, a publication of ASM International. It will be made available online some time later on. Interested readers will find there, besides the article summarized above, another one with guidelines for obtaining NADCAP accreditation, and one on the influence of Industry 4.0 meeting Heat Treatment.

Variety of complex geometry components that are routinely induction hardened. [From HTProDec16, page 12]

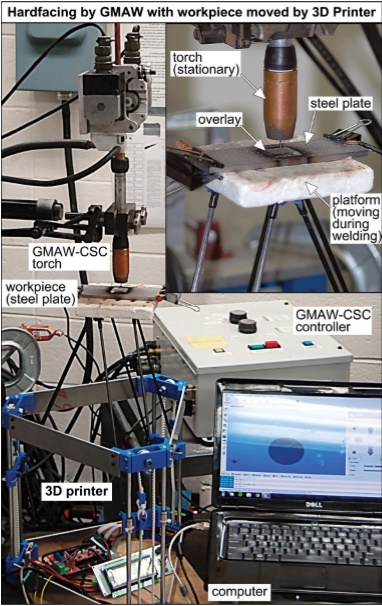

4 - Filler Metal for Ni-WC Hardfacing

A research article on hardfacing by Gas Metal Arc Welding (GMAW) with filler metal of Nickel embedded with tungsten carbide (WC) was published in the Welding Journal supplement in the December 2016 issue at page 251-s. The cladding of Ni-WC has exceptional abrasion resistance and moderate corrosion resistance suitable for diverse applications. In the reported research, the conventional GMAW process was compared with controlled short circuiting GMAW (GMAW-CSC). The second process was found to have a much wider window of acceptable parameters for making a smooth cladding without much spatter. Also the dilution increase with heat input was found less important for the second process, and excessive dilution can have a significant effect on the performance of the cladding. It was found that the weaving pattern of the welding gun can significantly affect the thickness uniformity of the clad layer and its dilution by the base metal. In the experimental setup of this research the optimum pattern was found by using a low-cost 3D printer to move the workpiece under a stationary gun. The controlled short circuit capability permitted to reduce melting of the steel substrate, thus preserving the hard phase for its intended use. This summarized article is titled: Interested readers are invited to seek all additional details exposed in the full version mentioned above.

3D printer (lower left corner) supporting and generating 3D motion of the steel workpiece under the welding gun to allow printing filler metal on steel

5 - Online Press: recent Welding related Articles Granta Design Announces GRANTA MI v10 Welding Equipment and Supplies: The Global Market Welding Robotics Market: New Growth Opportunities By 2021 Infrared Cameras Improve Quality of Plastic Welding Process Linear Friction Welding of Ti 6Al 4V for Aerostructure Applications

6 - Terms and Definitions Reminder Inert Gas is one that normally does not combine chemically with material even at elevated temperatures. Joint Clearance in brazing and soldering is the distance between the faying surfaces of a joint. Knurling means impressing a design into a metallic surface, usually by means of small, hard rollers that carry the corresponding design on their surfaces. Also to roughen the surface to prepare it to accept thermal sprayed powder for improved adherence. Lap Joint is that formed between two overlapping members in parallel planes. Machining Allowance is the additional material provided beyond the finished contours on a casting, forging or roughly prepared component which is subsequently removed in machining to size, as likely to contain imperfections. Neutral Flame is an oxyfuel flame regulates so as to be not oxidizing nor reducing. Out-of-position Welding indicates a welding position other than flat or horizontal, i.e. vertical, up or down, and overhead. Peel Strength is the force required to separate two adherent surfaces joined by a suitable process, by peeling them away from the joint.

7 - Article: AWS Roadmap on Global Engagement.

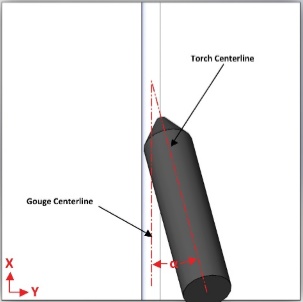

An important initiative started by AWS is briefly reviewed in a note published at page 44 of the December 2016 issue of the Welding Journal, concerning the elements of a strategy for keeping the Society open to meet the near future challenges and better prepared to provide needed solutions. It all started with a survey of members to help define AWS mission and the ways to improve the areas of focus in view of establishing a Global Strategy. Among the areas of importance isolated from the survey were shortage of welding personnel, professional development, certification, member and volunteer support/customer service, and global expansion. The methodology for the discussion was to isolate the area of concern, come up with the causes for this concern, and propose solutions. Several meetings of the committees appointed were conducted to elaborate on the recommendations. The oversight committee was charged to prepare a plan of action to address the five areas of focus and to propose it to the AWS Board of Directors for review and approval. The timeline for implementing the Global Strategy is January 2017. 8 - Site Updating: Plasma Gouging The website page of this month has been revised and a new section on Plasma Arc Gouging was added. The hint was taken from an article published in the December 2016 issue of the Welding Journal at page 38. The fundamentals of this process are briefly reviewed there and some guidance is given for the selection of correct parameters. It is stated that while its use increased in the last decade, offering a safe, efficient and cost-effective way to make a gouge, it is not yet employed in a wider way. In general terms, the quality of a gouge can be evaluated by determining if an operator has removed the correct amount of material in a controlled manner. Plasma has long since gained mainstream acceptance as a viable cutting alternative to oxyfuel, laser, electro-discharge machining, or waterjet. Although Plasma could be used effectively for a variety of common gouging applications it is lagging behind its potential, mostly because of lack of confidence. Interested readers can see the new section on Plasma Gouging in our page on Plasma-arc-cutting. Further information is available in the said article that all are advised to seek. All readers should be able to find what they need. If not from the Site Map, then by typing your question in the search window of any page of our website. Comments, feedback and questions are welcome: please use the Contact Us Form.

Offset angle method of gouging, top view (Z direction).

9 - Short Items

9.1 - Materials Characterization consists in the use of various analytical methods (spectroscopy, microscopy, chromatography, etc.) to describe those features of composition (both bulk and surface) and structure (including defects) of a material that are significant for a particular preparation, study of properties, or use. Test methods that yield information primarily related to materials properties, such as thermal, electrical, and mechanical properties, are excluded from this definition. 9.2 - Nanotechnology is a term used to describe many types of research which exploit phenomena and structures that can only occur at the nanometer scale, where the characteristic dimensions are less than about 1,000 nanometers or 1 micrometer (1 nanometer = 1x10-9 meter). The properties of materials become markedly different when their size approaches that of a few hundreds or tens of atoms. Nanotechnology requires understanding and control of matter at dimensions of atoms and molecules, to manipulate them individually and place them in a pattern to produce a desired structure. 9.3 - Orbital tube welding (OTW), is a mechanized system that permits to weld stationary tubes end to end or to tube sheets or to fittings. It consists generally in Weld Heads suitable for a certain range of tube diameters containing a special GTAW (Tig) torch which orbits around the joint. A weld schedule has to be established to ramp the current up from zero to the maximum appropriate for the thickness, and then, after some more than a full turn, to ramp it down back to zero. Depending on the requirements, special Heads can be used that allow multiple pass welding, as could be done manually. Welding is generally performed autogenously (without filler metal) but when needed a wire feeder can be added. For pressure resistant piping and for heavy joints, orbital welding is being done with special GMAW (Mig) or FCAW units, at much higher deposition rates. Power sources of different types can be employed, with the coordination being assured either manually or by microprocessor control. 9.4 - Passivation is: (1) A reduction of the anodic reaction rate of an electrode involved in corrosion. (2) The process in metal corrosion by which metals become passive. (3) The changing of a chemically active surface of a metal to a much less reactive state. 9.5 - Quantitative Metallography is a specialized discipline that makes use of computer aided picture analysis of visible features appearing under the microscope (and projected on a screen) on the surface of prepared specimens. By recognizing, grouping and performing simple geometric calculations on certain distinctive characteristics of the examined specimen surface, the technique permits to quantify their appearance and frequency. By these means the size, the aspect ratio and the amount of one or more phases in a given section can be expressed as a fraction of the matrix area. The correlation of the relative geometric properties as observed in metallographic sections, to the physical behavior revealed by testing, permits to perform studies and to use Quantitative Metallography as a tool for quality control. 9.6 - Radiant Tubes are used as heating systems for industrial heat treatment furnaces. Fuel is generally natural gas, but cost calculations should include also expenses relative to mandatory emission controls. Recirculating or regenerative types can recover at least part of the heat by using it to preheat combustion air. Recuperative burners add complexity to design but provide better fuel efficiency, temperature uniformity and reduced temperature exhaust gases. Ceramic radiant tubes of better quality and higher reliability than in the past are finding increased uses in higher temperature furnaces.

10 - Explorations: beyond the Welder Canadian Scientists Warn U.S. Colleagues: Act Now to Protect Science under Trump The Forgotten Life of Einstein's

First Wife

How to Convince Someone When Facts Fail

The Worst Wildlife Conservation Stories of 2016

The Most Popular Science Stories of 2016

11 - Contributions: Beware of Inadequate Welding Screens

An article published in the December 2016 issue of the Welding Journal at page 82 warns against the lack of protection that certain transparent screens, installed in welding booths, offer to bystanders' eyes. In fact the screens should permit to see the activity of welders engaged in their work, especially for alerting emergency help in case of need. Regular acceptable screens should filter out all dangerous ultraviolet and infrared radiation. It is stressed that screens of blue color do not offer such a protection and therefore should be banned from use. The matter is regulated by AWS F2.3M:2011, Specification for Use and Performance of Transparent Welding Curtains and Screens, but not all screens in the market meet all requirements. Therefore users are urged to check the products they install to guarantee to their welders adequate protection. Typically, screens passing the AWS standard are available on the market in red, orange, yellow, green, and bronze color. Screens passing the standard will filter hazardous blue light while allowing sufficient light for transparency and safety. Be sure your screens in use are conforming to requirements.

Welding screens filter hazardous radiant energy while allowing people to safely see the welder and welding operation. [From the Welding Journal December 2016 page 82]

12 - Testimonials On Mon Dec 12 06:47:03 2016, the following results were submitted from the "Form 5" on welding-advisers.com: Name: Atolani Bakare Wow. Thanks for replying. I'll check for some Chinese companies online and ask 13 - Correspondence: a few Comments Referring to the article on Welding Thermoplastics that was published (11) in the last issue of Practical Welding Letter (PWL#160), that reported on a long plastic pipeline for transporting cooling seawater to an onshore installation, our kind Correspondent and Mentor Anthony Rangus, who is already well known to our readers, sent us the following Comments: "Very few engineering companies used HDPE above grade. Suggest your readers go to "www.performancepipe.com" and look at Bulletin: PP 814-TN. Pay careful attention to linear expansion due to temperature changes and the hoops one must jump through for restraint design, expansion loop design etc. The costs become prohibitive, which is why we NEVER put HDPE above grade. We had some real bad experiences, even before the piping system was put into service. I have seen failures where the piping was sitting in the trench prior to any backfilling. Do not let great UV resistance be a selling point." Then he answered again to my doubts with the following message: "Elia, I read the entire article and was not being critical of what they accomplished. My employer spends a lot of money forcing our installation forces to qualify HDPE bonding procedures and imposes a significant amount of production bond destructive testing. We also impose very strict requirements on personnel qualifications. My sole reason for writing to you was to point out that when placing HDPE piping systems above grade, the large thermal expansion coefficient of HDPE can be a real issue when it comes to thermal stress, expansion loops, pipe supports etc. When someone touts HDPE's UV resistance, people may get the impression that one can just bond and lay it on the ground. This is why I referenced the technical bulletin. The phrase "jump through hoops" is a colloquial phrase meaning "huge effort". I hope interested readers will take note. 14 - Bulletin Board 14.1 - WIN EURASIA. 14.2 - 4th UKP Workshop: Ultrafast Laser Technology. 14.3 - BLECH

India.

See you next time...

Watch - The Video:

and also

BUILT BY: Click on this Logo NOW! No better way to get to know SiteSell, Specific questions about SiteSell?

Copyright (©) 2017, by Elia E. Levi and

Back to Past Issues of PWL.

|

||||||||||||||

| Back to Back Issues Page |