| Back to Back Issues Page | ||||||||||||||

|

||||||||||||||

|

PWL#162, Tips on GMAW Guns, Distortion Control, Nanoparticles Doping, Nanostructured Metal February 01, 2017 |

||||||||||||||

| We hope you will find this Letter interesting and useful. Let us know what you think of it.

PWL#162

PWL#162, Tips on GMAW Guns, Distortion Control by Welding with Trailing Reverse Side Flame Heating, Nanoparticles Doping of a MoNi Brazing Filler, Progress in nanostructured bainitic steels, Low Impedance Resistance Welding, MIG Welding Tips and much more...

February 2017 - Practical Welding Letter - Issue No.162

DON'T USE REPLY to send your

messages! Use the Contact Us form instead. This publication brings to the readers practical answers to welding problems in an informal setting designed to be helpful and informative. You are urged to pass-along this publication to your friends, if you like it, and if you think they may enjoy it. The addresses reported hereafter were live and correct at the time of their publication. Note: References to articles or other documents are given here in one of two forms. If they are URL's (Uniform Resource Locator), which is the analogue of an address, they begin with "http://..." or "www.". If the information is important to you as we

hope, you may save the selected pages in a suitable folder on your Computer for easy reference.

1 - Introduction 2 - Article - Tips on GMAW Guns 3 - How to do it well: Distortion Control 4 - Filler Metal: Nanoparticles Doping of a MoNi Brazing Filler 5 - Online Press: recent Welding related Articles 6 - Terms and Definitions Reminder 7 - Article: Nanostructured Metal 8 - Site Updating: MIG Welding Tips 9 - Short Items 10 - Explorations: beyond the Welder 11 - Contributions: Low Impedance Resistance Welding 12 - Testimonials 13 - Correspondence: a few Comments 14 - Bulletin Board

2 - Article - Tips on GMAW Guns

Those who work regularly with GMAW Guns know probably more on the subject than all others combined. Nevertheless it may pay to check from time to time if any new feature gains acceptance and why, or if maintenance procedures should be revised. Due to some unusual chance two articles on the subject were recently published in the January 2017 issue of the Welding Journal. The first, at page 44, offers six tips to extend the life of this essential piece of equipment by implementing best practices for selecting, installing, and maintaining the robotic GMAW gun. The first tip urges users to select a Solid Mount instead of a clutch to avoid collisions while assuring repeatability of tool center point (TCP). This is especially true for systems using through-arm style guns where cable assemblies run inside of the robotic arm. The second tip extols the advantages of using an Air Blast Feature to help enhance gun performance and cool down the gun between weld passes. The use of a simulation program is suggested to achieve the best results, also by selecting suitable nozzle and gun neck for a given job, to limit excessive robot movements. Also the use of a neck inspection system is suggested to improve productivity. Proper gun and cable selection and installation are key steps toward maximizing performance of the robotic GMAW gun. And finally thorough maintenance is recommended, spatter removal, and tracking of consumable life, to replace parts prior to failure. The second article, at page 48 suggests how to select a manual GMAW gun suited to the job to do. It starts by explaining the differences in cooling systems, detailing advantages and limitations of each type. It also dedicates some thoughts to how comfortable should be the gun in welders' hand, to reduce fatigue and increase productivity. It reminds that fume capture is available with certain guns, a welcome capability in some working environments. Finally a check list is proposed to help in troubleshooting when the gun is not up to the job. Readers should welcome the opportunity to refresh their knowledge and to improve their worth as alert and updated welders, by seeking and learning the original articles reported here.

[From the Welding Journal, January 2017, page 49]

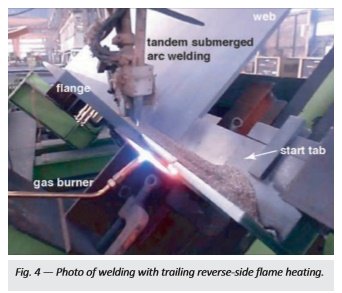

3 - How to do it well: Distortion Control

An article published in the January 2017 issue of the Welding Journal in the Welding Research Supplement at page 31-s highlights the principles involved in trying to control distortion right during the welding process and not as a corrective action to be implemented at a later stage. It is titled: The article reports on a study made to improve the geometric results of manufacturing plate girders in bridge construction by using trailing reverse side flame heating. Tandem submerged arc welding, which is the actual fabrication process used in bridge construction, was conducted to construct the plate girder in the controlled experiment. Among the distortions measured, both with and without trailing reverse side flame heating, were longitudinal and transverse shrinkage and bending distortions of the upper and lower flange plates, height and flatness of the web plate, and perpendicularity between the web and flange plates at both the upper and lower sides of the plate girder. The results showed the perpendicularity between the web and flange plates can be controlled successfully within allowable limits by welding with trailing reverse side flame heating without significant negative influences on other shrinkage and distortion. Furthermore, mechanical testing validated that yield and tensile strengths of the welds increase slightly and the Charpy value is not influenced negatively by trailing reverse side flame heating. Reverse-side heating located immediately below the weld torch, lessens the temperature gradient through the thickness of the welded materials to reduce the angular distortion that develops during welding. The effectiveness of welding with trailing reverse-side flame heating in controlling welding-induced geometric imperfections in the plate girder was validated through comparison with the allowable limits regulated by the specifications for highway bridges. Angular distortion of the flange plates and perpendicularity between web and flange plates can be successfully controlled without significant negative influences on other deformations. At the time of this publishing, the link for direct download is not yet available from the AWS website. It should appear any time soon: use the link: and then click on the link for RESEARCH PAPERS. The link to the above article should appear when the January 2017 issue is listed. Interested readers are urged to seek the original article, and maybe to try to improve distortion problems by implementing similar means.

[From the Welding Journal Welding Research Supplement, January 2017 page 33-s]

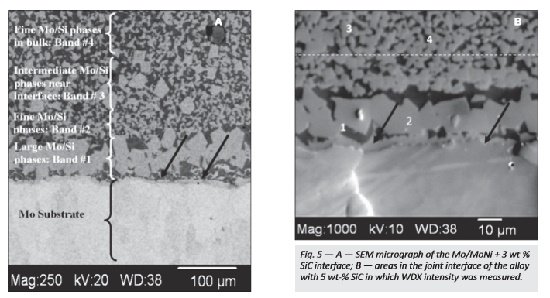

4 - Filler Metal: Nanoparticles Doping of a MoNi Brazing Filler

A research Article published in the January 2017 issue of the Welding Journal at page 11-s illustrates how Doping a binary eutectic MoNi brazing filler metal with SiC nanoparticles leads to enhanced mechanical integrity of the joint. Mo-Ni brazing filler metal (BFM) can be used for bonding refractory metals, e.g., molybdenum, rhenium, and/or porous tungsten provided the excessive wettability is somehow controlled. The article reports on previous work that showed that wettability change was achieved by adding nanoparticles of the same material (Mo-Ni) or a distinct material, such as SiC to a binary eutectic MoNi brazing filler metal. Then the mechanical properties of the formed brazed joint would be improved dramatically. The present study showed that shear stress and nanohardness improved upon doping, due to microstructural modifications. The failure of all brazed specimens occurred in the brazement zone and proceeded in a brittle mode. Besides single lap brazed joints shear tested to failure, also metallographic specimens were prepared to study phase morphology. The results of the study are summarized in the Conclusions reported hereafter. The shear strength of the brazed Mo-Mo joint with the Mo-Ni eutectic SiC doped filler was twice as high as that reported for nondoped filler. The major beneficial changes of the brazed joint’s morphology due to alloying of Mo + Ni alloy with SiC moderate additions take place in the joint microstructure. These changes are expressed in a transformation, a replacement of typical eutectic morphology consisting of dendrites embedded within a mixture of lamellae into a new type of refined microstructure consisting of a mixture of very small, evenly distributed eutectic crystals having cuboidal and trapezoidal forms. This transition expressed itself with changes in the forms and dimensions of crystallized eutectic phase components from rounded lamellae crystals to faceted ones. Interested readers are urged to seek the link to the original article, titled "Microstructure Refining of a MoNi Brazing Filler by Nanoparticles Doping", as it will be published in the AWS website, by following the procedure indicated for the previously reported article.

[From the Welding Journal Research Supplement, January 2017, page 16-s]

5 - Online Press: recent Welding related Articles Simulate Stamp, Welding and Product Assembly How we’re boosting awareness about welding in Nigeria GRANTA MI Improves Material Workflows and Simulation Support Technology Spotlight: Clearing out the blowback slag Are you lax on your PPE? It could cost you

6 - Terms and Definitions Reminder Quenching is usually understood as rapid cooling of heated metal that modifies the microstructure and produces favorable mechanical properties. Reducing Atmosphere is a chemically active protective atmosphere present in a suitable furnace, that will reduce metal oxides to their metallic state at elevated temperature. Sensitization is an occurrence affecting adversely the corrosion protective properties of stainless steel. This happens by heating the metal in the range from 600 to 900 °C (1100 to 1650 °F). Heating promotes the precipitation (gathering) of chromium carbides at grain boundaries. Stainless Metal depleted of chromium becomes susceptible to corrosion. Thermal Conductivity is an intensive property that indicates its ability to conduct heat. It is the quantity of heat transmitted, due to an unit temperature gradient, in unit time under steady conditions in a direction normal to a surface of the unit area. Undercut is a groove melted into the base metal adjacent to the weld toe or weld root, and left unfilled by weld metal. Vertical Down is a nonstandard term for downhill. Weld is the act of welding. X-Radiation is a form of electromagnetic radiation capable of penetrating certain materials for medical or technological inspection.

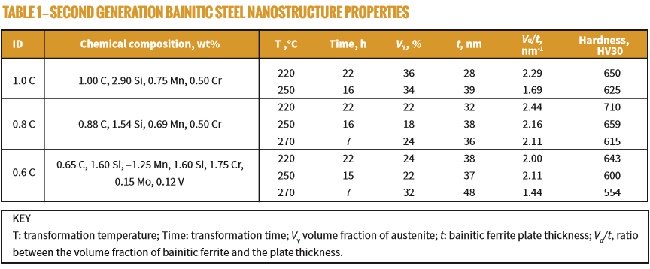

7 - Article: Nanostructured Metal

An important breakthrough was announced at page 21 in the January 2017 issue of Advanced Materials and Processes (AM&P), a publication of ASM International, where progress in nanostructured bainitic steels is detailed. The development involves new processing in bulk producing bainitic structures consisting of nano-scale ferrite crystals 20-60 nm thick interwoven by austenite. The material has the highest strength/toughness combination ever recorded in bainitic steels and has extraordinary rolling-sliding wear performance. The latest research into accelerating the bainite reaction suggests partial martensite transformation with subsequent transformation upon up-heating. Though the quenching and bainite transformation process occurs more quickly than in direct isothermal transformation, industrial production lines are not yet prepared for this kind of heat treatment. In the summary of this highly theoretical article, the following conclusions are reported. Nanostructured bainitic steels have been theoretically designed and manufactured using conventional industrial practices, achieving mechanical properties never recorded before in bainite structures. Bainitic steel microstructures consist of extremely fine plates of carbon-supersaturated ferrite and retained austenite. The increased solubility of carbon in ferrite might form a better basis for phase transformations theory on alloy design. Potential applications have yet to be fully explored. Interested readers with an eye to possible uses of these steels exploiting their exceptional characteristics are urged to seek the original text where names and contacts are available for follow up.

[From AM&P January 2017, page 22]

8 - Site Updating: MIG Welding Tips As advised above in the Introduction, the Page of the Month is simply expanded in its content by adding the information, supplied in this publication, providing additional tips on selection and maintenance of GMAW Guns. By adding this 162th issue of our newsletter Practical Welding Letter to the links of the above page, available at Mig Welding Tips the two references quoted above (2) in the article on Tips on GMAW Guns are now available to all readers, possibly helping them in selecting and maintaining equipment. All readers should be able to find what they need. If not from the Site Map, then by typing your question in the search window of any page of our website. Comments, feedback and questions are welcome: please use the Contact Us Form.

9 - Short Items

9.1 - Ultimate Strength is the maximum stress (tensile, compressive, or shear) a material can sustain without fracture. It is determined by dividing the maximum load by the original cross-sectional area of the specimen. 9.2 - Vibratory Stress Relief is a non-thermal stress relief method used by the metal working industry to enhance the dimensional stability and mechanical integrity of metallic components. 9.3 - Waterjet Abrasive Machining is a hydrodynamic machining process that uses a high-velocity stream of water with injected fine abrasive particles to cut hard and dense materials. 9.4 - X-Ray Fluorescence is the emission of characteristic "secondary" (or fluorescent) X-rays from a material that has been excited by bombarding with high-energy X-rays, widely used for elemental analysis and chemical analysis. 9.5 - Yield Strength is the stress at which a material exhibits a specified deviation from proportionality of stress and strain. An offset of 0.2% is used for many materials, particularly metals. 9.6 - Zincrometal is a steel coil-coated product consisting of a mixed-oxide underlayer containing zinc particles and a zinc-rich organic (epoxy) topcoat. It is weldable, formable, paintable, and compatible with commonly used adhesives. Zincrometal is used to protect outer body door panels in automobiles from corrosion.

10 - Explorations: beyond the Welder The War on Facts Is a War on Democracy Cosmic Lenses Show Universe Expanding Surprisingly Fast New Exosuit

Fabric Could Boost Mobility in People with Disabilities A New Antarctic-Proof Greenhouse Heads South to Polar Scientists Climate Change Is Raising Flood Risk in the Northern U.S.

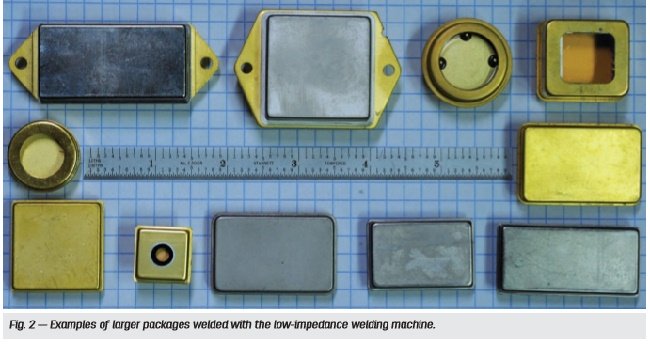

11 - Contributions: Low Impedance Resistance Welding

A most interesting article was published in the January 2017 issue of the Welding Journal at page 38 concerning developments in low impedance resistance welding machines built to perform long perimeter resistance welding for sealing purposes with a single electric discharge. Such applications save much longer time needed for alternative progressive seam welding processes and avoid excessive heating of nearby sensitive locations. The concerns which helped define equipment characteristics for this specific use were: 1) welding expulsions, 2) limited heating and 3) residual stress effects. Early semiconductors were frequently hermetically sealed, using resistance welding, in dry gas-filled metal packages. However with growing device size and new packaging technologies, the old resistance welding was found inadequate to provide defect free hermetic seals, mainly because of weld expulsions. In time it was found that much of the problem is caused by the relationship between the resistance of the welding equipment and the weld itself. Specifically, it is because the resistance of the weld can be low relative to that of the welding machine. Other processes were developed providing sequences of many small overlapping spot welds but with considerable time and cost disadvantage vs. a weld that can seal the entire perimeter with a single discharge lasting a few milliseconds. Advancement in the technology had to wait until recent times when the understanding that the electrical and physical characteristics of resistance welding equipment could affect the quality of the weld finally dawned upon those looking for breakthroughs. The change in attitude of experts trying to quantify the characteristics of resistance welds while neglecting to specify the welding machine type, occurred with the development of low impedance welding equipment. These "constant voltage" welding machines had still built in limitations that needed to be overcome. The developers of the new resistant welding machines had the goal to design, construct, and utilize resistance welding equipment that displayed the low-impedance welding characteristics of constant voltage operation without the weld current limitations posed by constant voltage welding equipment. The article goes on with the observation that single-discharge resistance welding remains the most cost effective and reliable method available for long perimeter seal joints. The welding system described resolves all manufacturing requirements in a unique and elegant manner. It continues by explaining the importance of impedance control in resistance welding and with a discussion on how to determine if a lower impedance welding technology would be advantageous in any particular situation, and it finally lists the advantages of using it for welding hermetic seals. Interested readers are urged to seek the original article where they will find additional essential details and the link to contact the author.

[From the Welding Journal, January 2017, page 39]

12 - Testimonials

Name: John Diehl On Sun Jan 01 12:48:09 2017, the following results were submitted from the "Form 5" on welding-advisers.com: Hi Elia, Your efforts produce lots of points regarding innovation and development that I would otherwise never get to see. It is like an ongoing education. I follow some of the links and am amazed at what has happened since I started so long ago. I love the topic and have been at it since 1976 - Oxy Acetylene, all self taught except one Vo-Tech type course in TIG. I have most of the modern stuff now MIG - TIG - Spot - but Laser and Microwave are pretty far out of reach since all I do in this realm is self funded. Retiree budgets don't go far towards some of the newer methods. As a curiosity I looked up what it would cost to replace my now old TIG machine - ghastly! Almost twice what I paid for my machine. There is no one with whom I am able to discuss anything welding related so your letter fills a very nice niche. Thank you again for work well done. I hope it is as rewarding for you as it is to those of us out here reading it and sharing the discoveries you include. Kindest regards, John Diehl 13 - Correspondence: a few Comments It is amazing that after so many years that our website is available online, many correspondents still don't know what is our real job (welding and metallurgical consultancy). We are asked quotations for execution of welding or brazing jobs, or we are offered materials for sale as if we could have interest in purchasing. Most amazing are those who, without a word of introduction, start by writing "I want..." as if our unique job was to sit here ready for their requests. Fortunately we have also kind readers, like the one quoted in the previous section, who express their appreciation, and I gladly admit that searching new welding developments for unknown readers is indeed rewarding to me as suggested above. 14 - Bulletin Board 14.1 - The 4th Lightweight Vehicle Manufacturing Summit 2017. 14.2 - WIN EURASIA Metalworking 2017 14.3 - 4th UKP Workshop: Ultrafast Laser Technology.

See you next time...

Watch - The Video:

and also

BUILT BY: Click on this Logo NOW! No better way to get to know SiteSell, Specific questions about SiteSell?

Copyright (©) 2017, by Elia E. Levi and

Back to Past Issues of PWL.

|

||||||||||||||

| Back to Back Issues Page |