| Back to Back Issues Page | ||||||||||||

|

||||||||||||

|

PWL#169, AI f/Aerospace, Wire Brushes for Cleaning, Advance in Al Robotic Welding, New ASME BPVC IX September 01, 2017 |

||||||||||||

| We hope you will find this Letter interesting and useful. Let us know what you think of it.

PWL#169 PWL#169, Aerospace Applications of Additive Manufacturing, Selecting Wire Brushes for Weld Cleaning, Advances for Filler Metal fusing in Aluminum Robotic Welding, New 2017 Issue of ASME BPVC Section IX, A Study on argon/hydrogen blend as shielding gas for welding of deposit of corrosion resistant overlays (CROs), usually Inconel 625, on high-strength steels and much more... September 2017 - Practical Welding Letter - Issue No.169DON'T USE REPLY to send your messages! Use the Contact Us form instead. This publication brings to the readers practical answers to welding problems in an informal setting designed to be helpful and informative. You are urged to pass-along this publication to your friends, if you like it, and if you think they may enjoy it. The addresses reported hereafter were live and correct at the time of their publication. Note: References to articles or other documents are given here in one of two forms. If they are URL's (Uniform Resource Locator), which is the analogue of an address, they begin with "http://..." or "www.". If the information is important to you as we hope, you may save the selected pages in a suitable folder on your Computer for easy reference. 1 - Introduction 2 - Article - Aerospace Applications of Additive Manufacturing 3 - How to do it well: Selecting Wire Brushes for Weld Cleaning 4 - Advances for Filler Metal fusing in Aluminum Robotic Welding 5 - Online Press: recent Welding related Articles 6 - Terms and Definitions Reminder 7 - Article: New ASME BPVC Section IX 8 - Site Updating: Welding Aluminum 9 - Short Items 10 - Explorations: beyond the Welder 11 - Contributions: a Study on argon/hydrogen blend 12 - Testimonials 13 - Correspondence: a few Comments 14 - Bulletin Board

2 - Article - Aerospace Applications of Additive Manufacturing

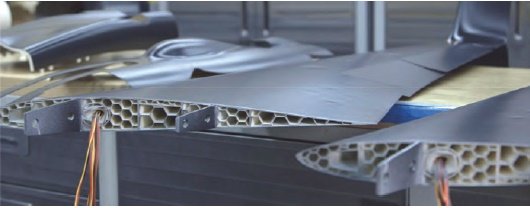

The first part of an article on the above subject was published at page 36 of the July/August 2017 issue of Advanced Materials and Processes, a magazine of ASM International. After a brief review of the first attempts to tap the great economic advantages of Additive Manufacturing (economy of energy and materials) as compared to the traditional Subtractive Manufacturing that was implemented by removing excess material, the article emphasizes that the mechanical properties obtained on new items must meet those of the best ones manufactured by older technologies. New Specifications devoted to AM are being developed to assist both manufacturers and users in describing requirements and in assessing results. Fabrication procedures must be firmly known and repeatable, accepted by the customer. Mechanical properties must meet design values statistically proven by the supplier. Furthermore AM part quality must be assessed by developing confidence in nondestructive evaluation to detect harmful defects possibly generated during manufacture. The article makes the point that design engineers, trained in subtractive manufacturing, must evolve in education, practice and mindset to extract the maximum out of the capabilities of AM. Design, manufacturing and cost issues were always present in the traditional approach. In an AM environment, the need for collaboration is magnified, to find the best combination of possibly conflicting requirements. Design iterations can be produced quickly, while determining manufacturing and cost implications may take longer to appear clearly to all involved. However the determination of ideal design should reduce significantly the product development time. As design may affect productivity issues, design may be different for one-off prototype vs. that intended for significant production quantities. Required post-processing operations must be taken into account during development, especially if alternatives are available. Specific issues like the removal of parts from the build plate, stress relief, hot isostatic pressing and powder removal and recovery are also discussed in the article which introduces non specialized readers into the special mindset needed to tackle the AM transition.

Final part build model (complex air foil), for which the build by additive manufacturing will be inspected. [From Adv. Materials and Processes, July/August 2017 - page 38] 3 - How to do it well: Selecting Wire Brushes for Weld Cleaning

If asked, nobody in a welding shop would answer that any wire brush would do for cleaning a joint before welding or for cleaning a weld once done. But it is what is being used in practice that will determine if the discipline to keep different brush types segregated and selected according to approved use is indeed followed. It is quite possible that, in a not properly supervised shop, anyone would grab whatever brush is handy at the moment, without any further thought, despite risky quality consequences. An article on proper brush selection was published at page 82 in the August 2017 issue of the Welding Journal. While straightforward information is presented, the article is recommended reading, in that it may remind a few facts that should never be forgotten. The article notes that the most common brush filaments material used for weld cleaning are carbon steel wire and stainless steel wire, the first being commonly used for steel constructions. For stainless steel welded fabrications, stringer bead knot wheels brushes are common, where the knot diameter, achieved by uniformly twisting multiple strands of wire together, is between 3/16 and 5/16 in. (4.8 and 8 mm) and the most common wire size is 0.020 in. (0.5 mm). The most widely used brush for weld preparation is 4 in. (100 mm) outer diameter (OD), but other diameters are also available. These brushes are usually mounted on an electric angle grinder. The guards should always be mounted on the machine when in use, as personal protective equipment and eye protection. Cup brushes, 2 3/4 in. OD (~ 70 mm) may be preferable for certain jobs for their larger contact area. Encapsulated cup brushes feature urethane filler between wire strands tend to not release wire bits and are therefore more attractive tools for health and safety. End brushes, suitable for more localized cleaning work, look like a single knot in a cylindrical head, ending in a 0.25 in. (6 mm) round stem to be mounted in die grinders, drills or collets. For use on stainless steel fabrications, brushes must not be contaminated by occasional cleaning of different materials. The recommended operating speed is generally much less than the maximum safe free speed printed on the wheels. Interested readers are urged to seek the original article to learn details not reported here.

SINGLETWIST® end brush cleaning hard-to-reach-weld joint. [From Welding Journal, August 2017 - page 83] 4 - Advances for Filler Metal fusing in Aluminum robotic welding

An article published at page 46 in the August 2017 issue of the Welding Journal explains the challenges confronting those using robotic gas metal arc welding (GMAW) for joining aluminum. It starts by reminding the most evident differences from welding steel, consisting in the high thermal and electrical conductivity of aluminum and the low melting point relative to its oxide layer. Then it reminds that gaps should be no more than half or even one quarter the thickness of the thinnest member. And also that tracking the joint through the arc is not possible because the output amperage does not change significantly with a change in electrical stickout. However it may be possible to use touch sensing technology, albeit at much higher voltage. The article continues by informing readers that advanced technologies were introduced to master the problems of robotic aluminum welding. The first innovation mentioned is AC automated welding obtained by coupling two DC power supplies of opposite polarity to provide square wave AC output, where the amount of time spent on the DC side of the wave is adjustable, which allows for full control of heat input. The automated welding system can reduce the amount of heat input, and thus penetration, at any given amperage or welding wire feed speed, offering increased control without melt through. The second is slope control, that allows the use of more heat input, by starting the arc at a higher amperage at the beginning of a weld then at the rest, to confront heat draining effect of aluminum. The third is synchro-weave that varies the amperage in sync with the weave, to allow to put more heat into the side that displays a bi-directional heat sink and less heat into the side that displays a single-directional heat sink. The last mentioned innovation is active or reciprocating wire feed technology that allows welding in short-arc mode without high level of spatter: this technology however requires a combination of a special robotic torch, wire feed-assist motor, and software. The article concludes that to find out the best technology for the robotic application concerned there is no better way than discussing the application with an expert. Interested readers are urged to seek the original article indicated above.

Active Wire or “reciprocating” wire feed technology is an alternative for automated welding of aluminum. The wire feeder reverses the wire feed direction after touching the weld pool, allowing for welding in the short-arc mode without high level of spatter. [From Welding Journal, August 2017 - page 48] 5 - Online Press: recent Welding related Articles Optimizing Your Robotic Welding Process

(Webinar) Miller Electric adds ArcReach capabilities Thermomechanical tank technology Galva Coat commissions automatic welding line for operation Welding Gas and Shielding Gas Market Outlook 2022 6 - Terms and Definitions Reminder Accelerating potential is that imparting velocity to electrons. Back weld is that made at the back of a single groove weld. Cast of wire is the diameter of the loop the wire forms when it comes off the spool. Depth of decarburization is the greatest depth of total carbon loss appearing in a light microscope when scanning the surface of a polished and etched cross-section of a suitable specimen. Electrical stick out is the distance from the end of the contact tip to the top of the welding arc Face reinforcement is the additional thickness deposited by the weld on the side of the joint from which the weld was done. Gap is a nonstandard term used for arc length, joint clearance and root opening. Helix is the distance a length of wire cut from a spool, approximately describing a circle, will rise from a flat surface. 7 - Article: New ASME BPVC Section IX

A thorough summary, detailing the changes introduced in the 2017 edition of the ASME Boiler and Pressure Vessel Code, Section IX, becoming mandatory January 1, 2018 for new qualifications, was published at page 46 in the August 2017 issue of the Welding Journal. As is widely known, BPVC Section IX deals with Welding, Brazing, and Fusing Qualifications. The review starts with global editorial revisions, with explanations on the perceived need for change. Then it explains the requirements of which documents take precedence when called for by other documents. Further down the page it explains a few cases where the dimensions of the coupon permit process qualification for a larger thickness range that was previously admitted. Other clarifications pertain to the P-number of metal overlays. A new process, low-power-density laser beam welding is explained and regulated. Changes were introduced for temper bead welding, by deleting previously excessive requirements. New rules were added to specify the width of tensile coupons, that was previously different in certain specifications, by making reference to a list of standards. An explanation is added for those looking for data in deleted documents. Another section deals with welder qualification changes. The term "density" referring to radiographic examination was removed because it is an integral part of Section V image quality requirements. For ultrasonic examination, the use of modern inspection techniques permits the use down to thickness that was not previously admitted. Additional observations explain why a certain footnote was revised to make it compatible with existing rules. Additionally, qualified welders are allowed to tack weld. Base metals and filler metals were added and were assigned P-numbers. A new filler metal specification, SFA-5.36 was added, to replace 5.20 and 5.29, which are not withdrawn for the time being. A few changes were applied to qualification of brazing processes and of plastic fusing. A link is provided to interpretations, to be found at http://cstools.asme.org/interpretations.cfm For those who need to find them, the article advises that all changes can be readily identified in the "Summary of Changes" found in the front of Section IX. Readers are invited to seek the original article, an essential introduction to the changes in the new 2017 Edition of BPVC Section IX. 8 - Site Updating: Welding Aluminum The website page indicated is now updated by including also a reference to the article published above (4) in this PWL#169, on Advances for Filler Metal fusing in Aluminum robotic welding. Readers working on aluminum fabrications by means of robots, or even those just considering such a move, are strongly advised to seek the original article quoted, to determine if any of the mentioned advancements is likely, if applied, to contribute to the success of their operation. It is important to note that aluminum welding requires special attention and experience gained through dedicated efforts to learn details from all available sources. The affected page is found by clicking on Welding Aluminum. 9 - Short Items 9.1 - Machinability is the relative ease of machining a metal, meaning the removing of material from a metal part, usually using a cutting tool, and usually using a power-driven machine. 9.2 - Native metal is any deposit in the earth's crust consisting of uncombined metal and also the metal in such a deposit. 9.3 - Offhand Grinding means performing metal removal using a grinding wheel, where the operator manually forces the wheel against the work, or vice versa. It often implies casual manipulation of either grinder or work to achieve the desired result. Dimensions and tolerances frequently are not specified, or are only loosely specified; the operator relies mainly on visual inspection and fitting to the corresponding element, to determine how much grinding should be done. 9.4 - Pack Nitriding is a method of surface hardening of steel in which parts are packed in a steel box with a nitriding compound and heated to elevated temperatures to diffuse the compound into the metal. 9.5 - Quench Aging is induced by rapid cooling after solution heat treatment. 9.6 - Radioactive Element is one that has at least one isotope that undergoes spontaneous nuclear disintegration to emit positive particles, negative particles, or rays.

10 - Explorations: beyond the Welder State Department Science Envoy Explains Why Trump Drove Him to Resign A Partial Eclipse Is Interesting; a Total Eclipse Is Mind-Blowing White Nationalists Are Flocking to Genetic Ancestry Tests--with Surprising Results Astronomers Capture Best-Ever Image of Alien Star Can a Crowdsourced AI Medical Diagnosis App Outperform Your Doctor? 11 - Contributions: a study on argon/hydrogen blend

It may come to some as a surprise that argon/hydrogen blends are currently used as shields for welding steels. In effect, the known danger of hydrogen- induced cracking (HIC) may be responsible for the general banishment of hydrogen containing blends. An article published at page 32 of the August 2017 issue of the Welding Journal explains the steps of a thorough study that was initiated to assess the real effects of hydrogen and to confirm or dispel the concerns affecting the issue. The special application considered was the deposit of corrosion resistant overlays (CROs), usually Inconel 625, on high-strength steels like 4130, 8630 and F22 for components in the oil and gas industry, using gas tungsten arc welding with hot-wire filler metal addition (GTAW-HW). It is reported that metallurgists working for the above mentioned industry are among the strongest opponents of hydrogen use because of HIC danger and for the damaging effects of hydrogen sulfide on carbon and alloy steel weldments. Furthermore fear of hydrogen explosion is diffused, although the flammability limit is at 4% concentration. The blend used for the study was 98% Ar and 2% H2. Hydrogen is reactive, reducing oxides and combining with oxygen present, and permitting to the weld pool to run hotter than when only argon is present. A brief account is offered of the first use of atomic hydrogen welding process, that was at the time, around 1930, the hottest temperature process available. Three coexisting conditions are necessary for HIC to occur in steel weldments: a crack susceptible hard microstructure and the presence of both stress and hydrogen. The primary goal of the study was to measure the amount of hydrogen present in the weld metal and to check if the addition of a small amount of hydrogen to the shielding gas would result in any degradation of mechanical properties of the weld metal zone, HAZ, or base metal. The article explains at length how the hydrogen content testing was performed and how the specimens were done. The conclusion is that when 98% argon/2% hydrogen shielding gas is used for joining high-strengthsteels, there is no evidence of any degradation of mechanical properties in the weld metal and HAZs, while the inclusion content of the weld deposit is reduced significantly. Readers skeptical of these conclusions and reluctant to adopt the suggested shielding gas mix are warmly encouraged to seek the original article and to confront the authors on any remaining doubts.

The top weld was made using argon shielding gas. [From Welding Journal, August 2017 - page 33] 12 - Testimonials Name: Joe Walker Details: Hi there, Hope this email finds you well! My name is Joe Walker, and I'm from Controlled Thermal Processing Inc. I'm writing to you on behalf of our President, Frederick J. (Rick) Diekman who is the author of Section 7 - Article - Cryogenic Processing - Part 2 - A Correction" published on your website here https://www.welding-advisers.com/PRACTICAL_WELDING_LETTER-PracticalWeldingLetterNo58.html I appreciate your featuring his contribution on your website, and was wondering if you could kindly include a link to our new site http://ctpcryogenics.com/ in the author bio. We are very proud of the work we do, and with the inclusion of a link to our site, we hope that your readers would be able to learn more about us and the industry, and visit our website. Please let me know if you need any other information, or if you have any questions. Thanks very much and I look forward to hearing from you soon. Regards, Joe Walker 13 - Correspondence: a few Comments I get a query. I answer by asking additional information, including complete description of the equipment or service requested. Simple, is not it? I get back the exact copy of the first query, with no additional information. My conclusion: the query is not serious enought to spend time on it. 14 - Bulletin Board 14.1 - Westec. 14.2 - Schweissen & Schneiden.

See you next time...  Watch - The Video: and also BUILT BY: Click on this Logo NOW! No better way to get to know SiteSell, Specific questions about SiteSell? Copyright (©) 2017, by Elia E. Levi and Back to Past Issues of PWL. | ||||||||||||

| Back to Back Issues Page |